Temperature field distribution non-contact measuring method in danger wastes thermal decomposition incineration furnace

A hazardous waste, non-contact measurement technology, applied in the direction of radiation pyrometry, measuring devices, optical radiation measurement, etc., can solve the problems that cannot truly reflect the distribution of the temperature field in the furnace, and the detection points are difficult to arrange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

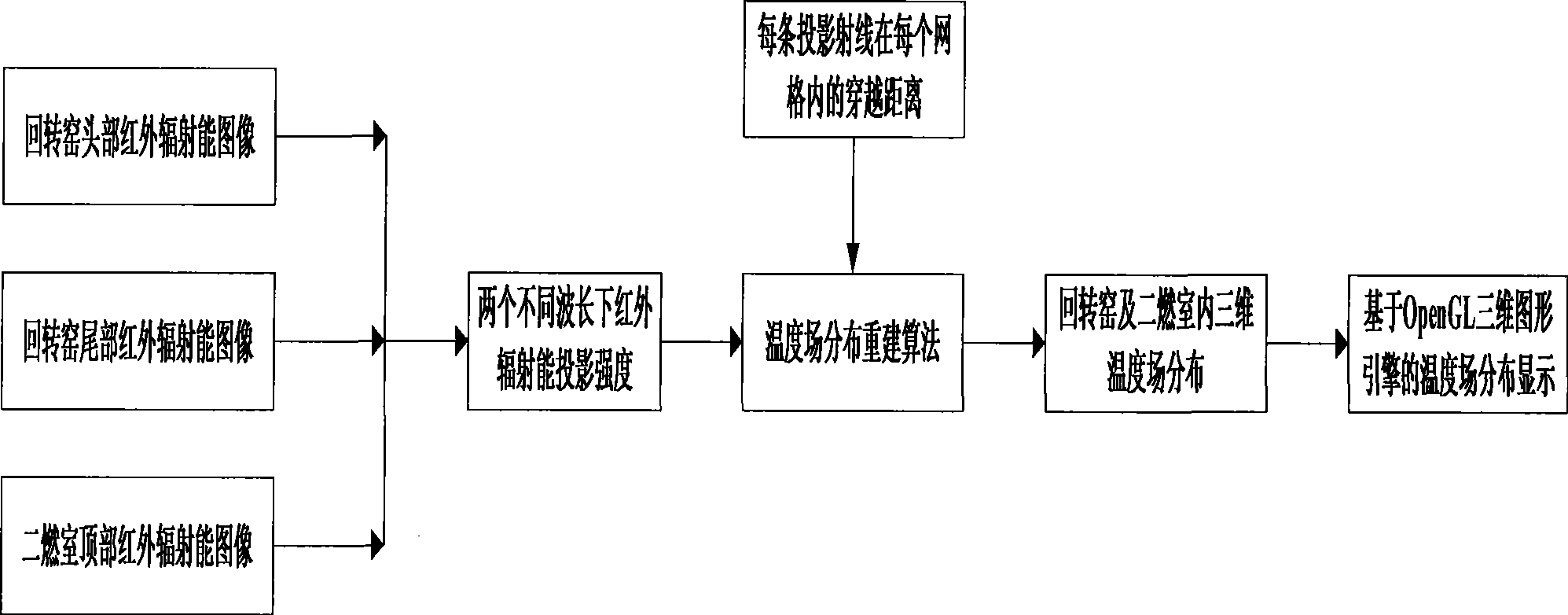

[0042] Taking the two-stage pyrolysis incinerator commonly used in the hazardous waste incineration disposal process as the measurement object, the steps of the non-contact measurement method for the temperature field distribution in the hazardous waste pyrolysis incinerator are as follows:

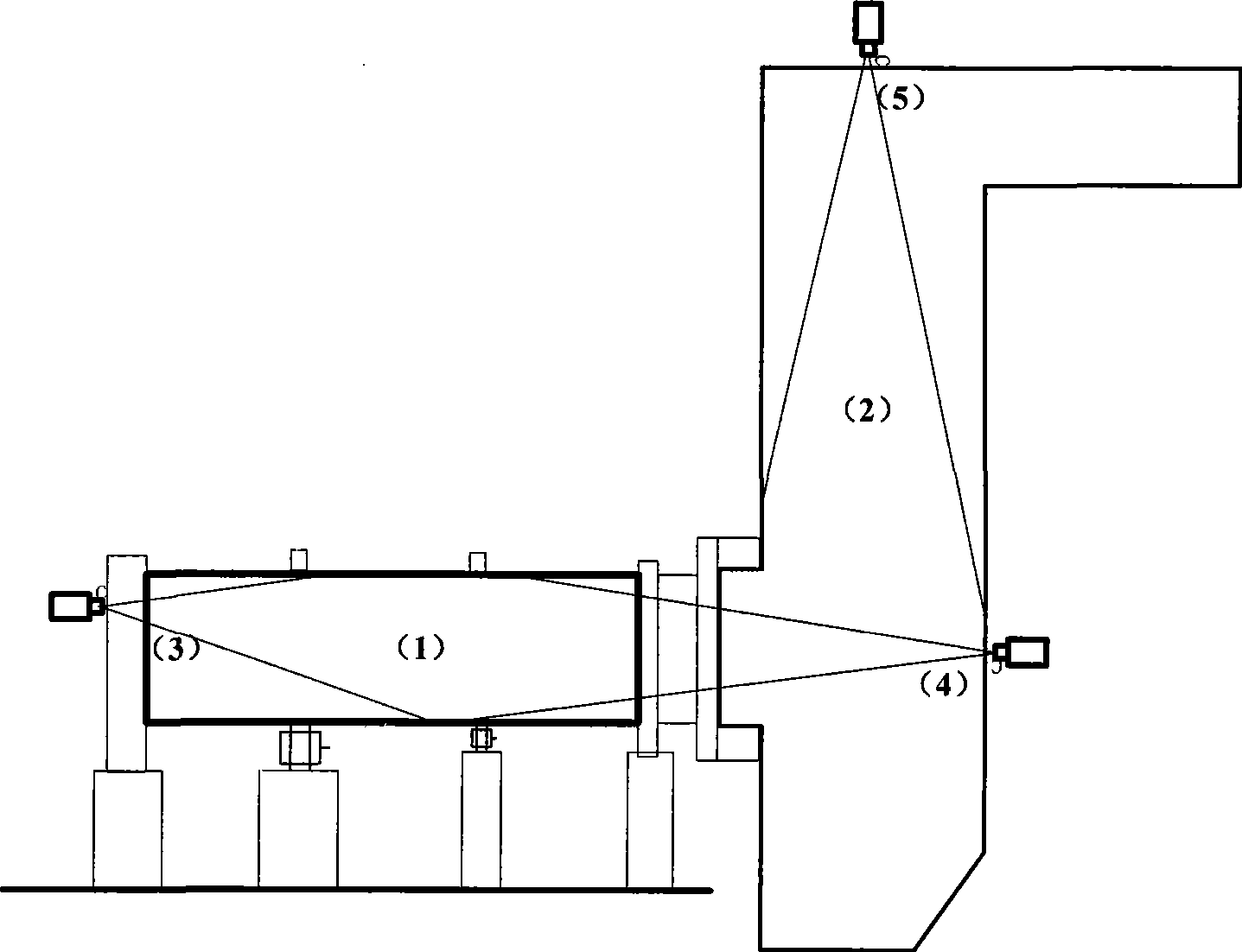

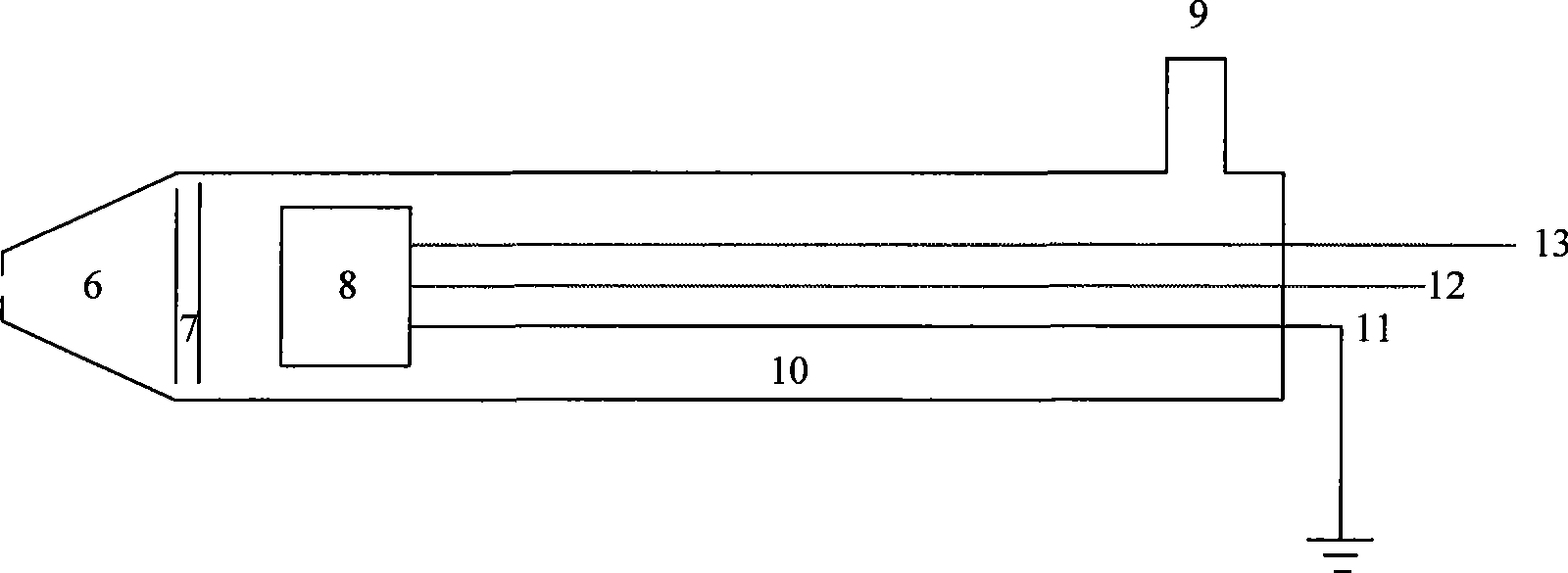

[0043] 1) At the head 3 of the rotary kiln, the tail 4 of the rotary kiln and the top 5 of the second combustion chamber of the hazardous waste incineration system according to figure 2 The infrared radiant energy image measuring gun is arranged in the manner shown, and the infrared radiant energy image is obtained in a non-contact manner. Measuring gun structure such as image 3 shown. The measuring gun must pass through the refractory insulation layer of the incineration system to ensure a viewing angle of more than 60°. The measuring gun is cooled by compressed air. The cooling air is sprayed into the measuring gun from the cooling air inlet 9. The cooling air is not reused. The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com