Optical fiber grating soil pressure sensor

An earth pressure sensor and optical fiber grating technology, which is applied in the field of earth pressure applications, can solve the problems that the earth pressure sensor cannot eliminate the influence of temperature, reduce the authenticity of measurement results, and cannot realize distributed measurement, etc., and achieves low cost, simple structure, and convenient cascade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

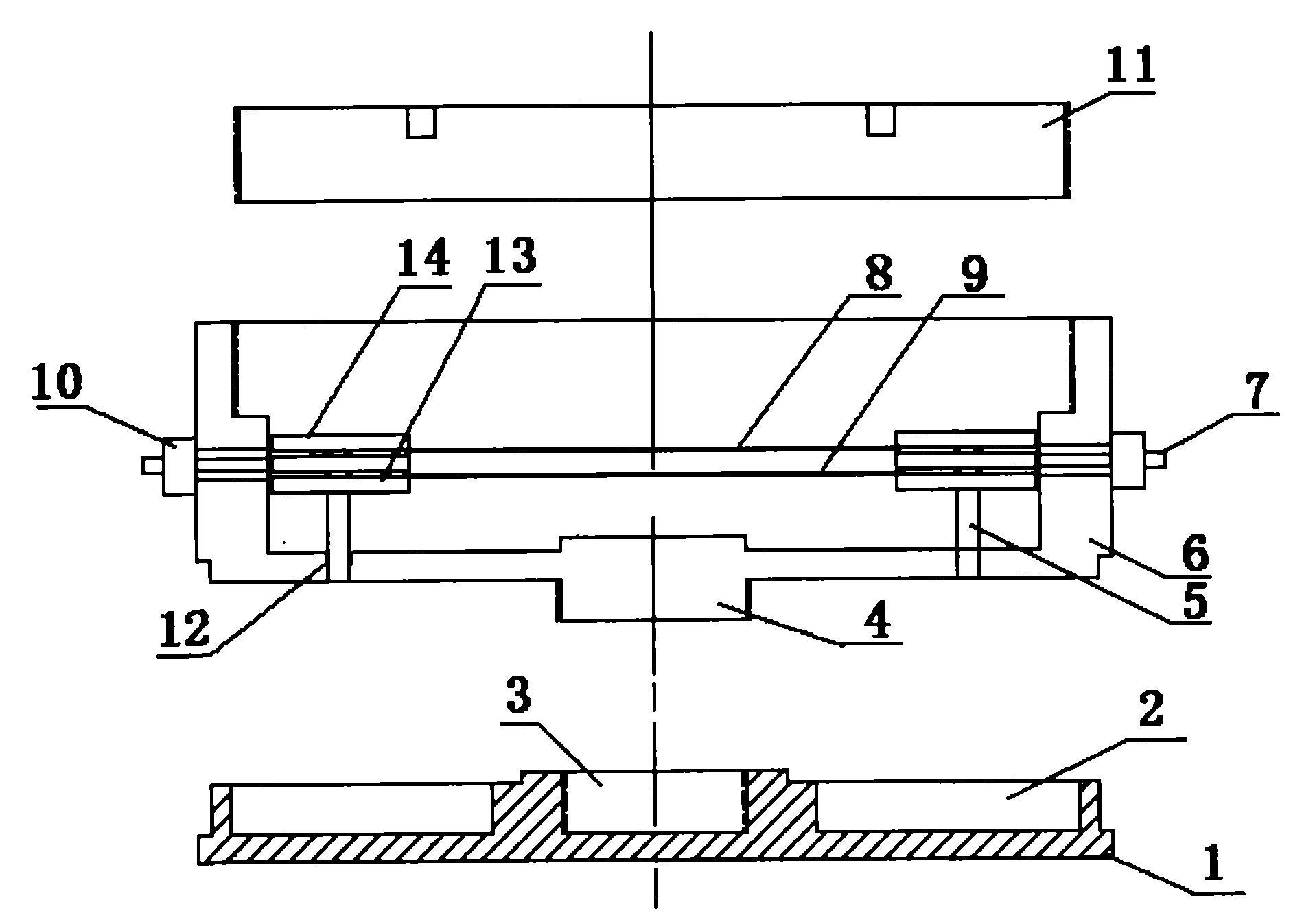

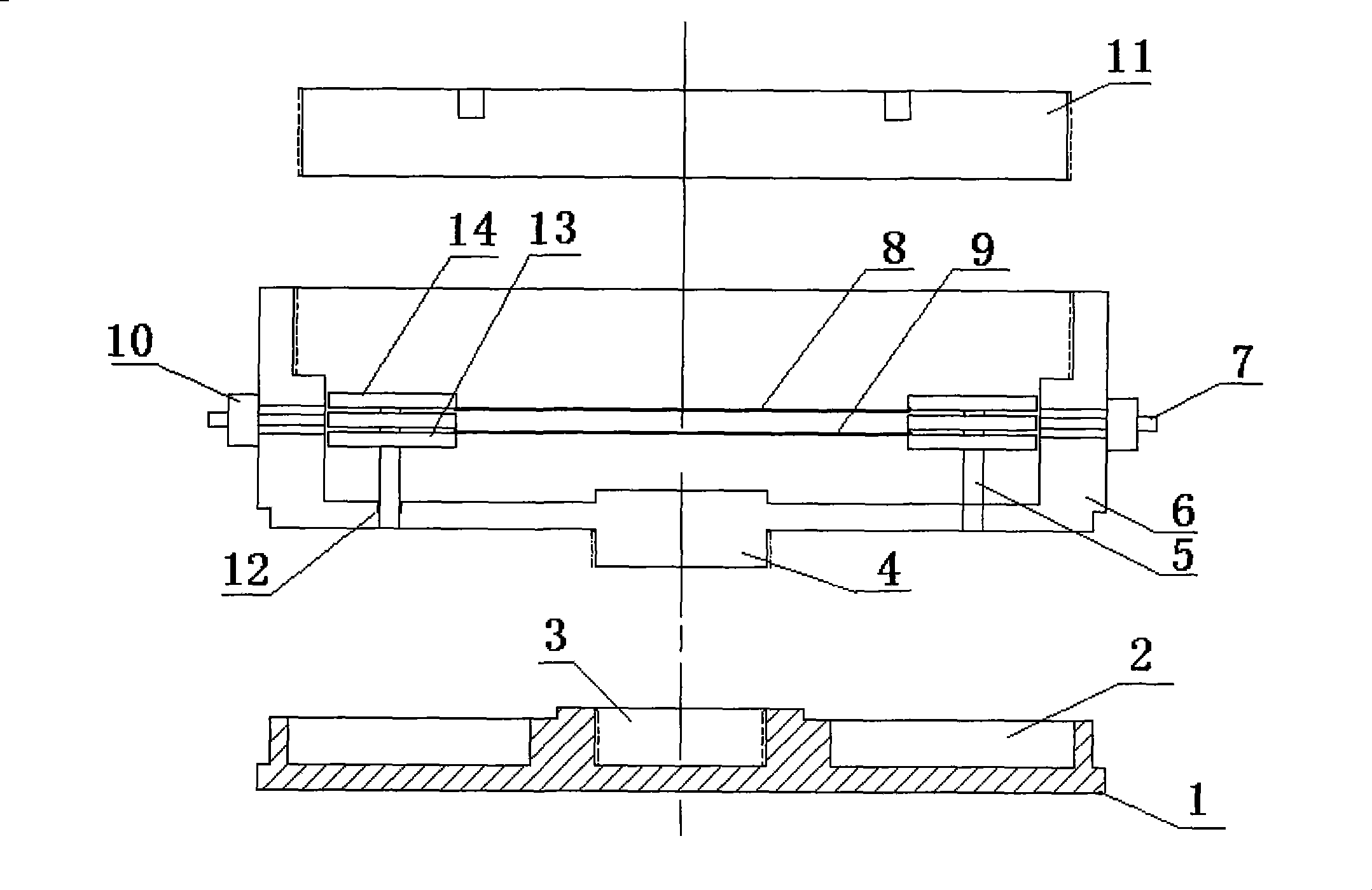

[0019] As shown in Figure 1, it includes a pressure bearing plate 1, a disc cover 11 and a circular cavity housing 6, the pressure bearing plate 1 and the circular cavity housing 6 are connected by threads, and the circular cavity housing 6 and the disc cover 11 are used Threaded connection; two wedge-shaped blind holes 12 are symmetrically opened at the bottom of the round cavity shell 6, and the two fixing columns 5 are wedged into the two wedge-shaped blind holes 12. The upper part of the fixed column 5 has a solid splint 13 and a buffer splint 14. The two symmetrical solid splints 13 are used to fix the two ends of the force-measuring grating 9, and the symmetrical buffer splint 14 is used to fix the two ends of the temperature compensation grating 8. The force-measuring grating 9 is connected in series with the temperature compensation grating 8, and after the force measuring grating 9 and the temperature compensation grating 8 are connected in series, the two ends are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com