System and method for calibrating terminal APC (Automatic Power Control) automatic production

A technology for automatic production and calibration systems, applied in transmission systems, transmission monitoring, electrical components, etc., can solve problems such as low production efficiency and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

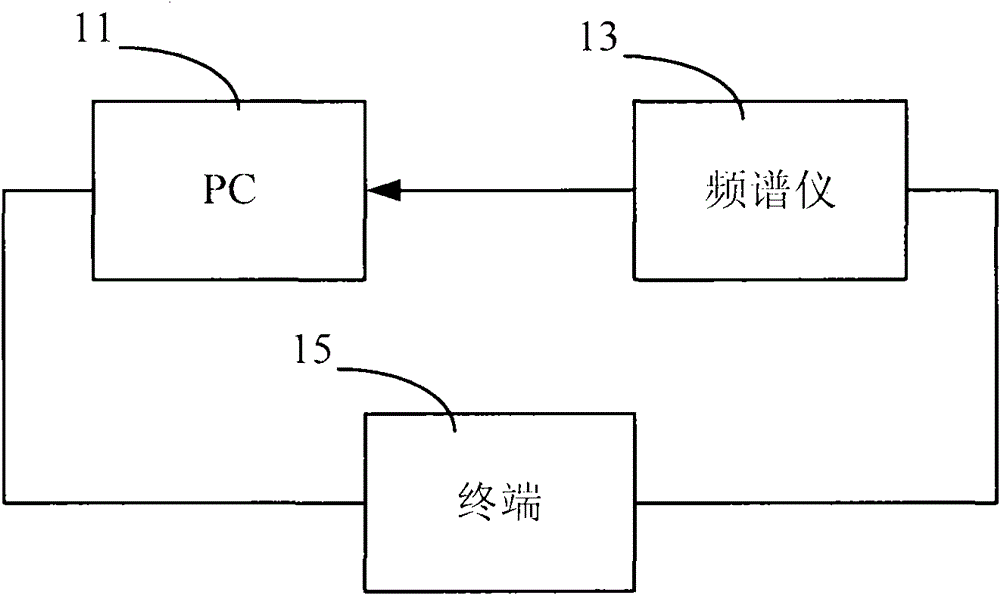

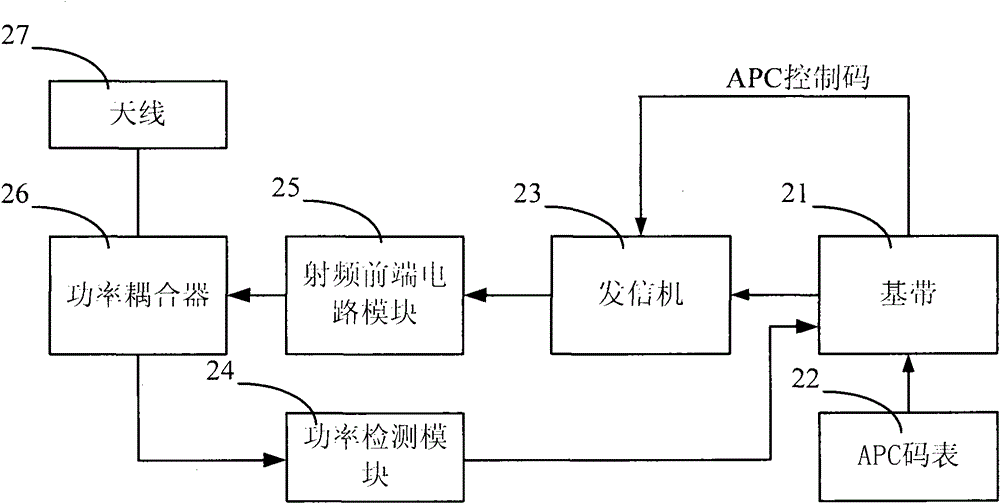

[0068] Embodiment 1 of the present invention provides a method for terminal 15 to perform APC automatic production calibration, such as figure 1 and figure 2 As shown, the method steps include:

[0069] Step 1: Calibrate the measurement error of the power detection module 24

[0070] A: The terminal 15 enters the production test mode under the control of the PC 11.

[0071] B: The baseband 21 of the terminal 15 first controls the transmission power of the transmitter 23 according to the APC code table 22 with the APC control code corresponding to the maximum transmission power level, and the transmitter 23 sends a pseudo-random waveform file according to the transmission power.

[0072] C: The power detection module 24 detects the power value transmitted to the antenna 27 through the power coupler 26, and returns the measured power value to the baseband 21.

[0073] D: The spectrum analyzer 13 reads the power value transmitted to the antenna 27 through the power coupler 26...

Embodiment 2

[0092] Embodiment 2 of the present invention also provides a method for terminal 15 to perform APC automatic production calibration, the method includes the following steps:

[0093] Step 1: Calibrate the measurement error of the power detection module. The calibration method is consistent with the method for calibrating the measurement error of the power detection module in Embodiment 1, and will not be repeated here.

[0094] Step 2: APC Automatic Production Calibration

[0095] Turn on the terminal 15 to enter the APC automatic production calibration mode.

[0096] 1, baseband 21 every frame sends a plurality of time slots, assuming that every frame sends the maximum number of time slots to be N, one calibration can complete the calibration of N power levels; The APC control code controls the transmission power of the transmitter 23 to send the pseudo-random waveform file, and the second transmission time slot is reduced by one power level, and the APC control code correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com