Vision inspection apparatus and plate-establishing inspection device and method therefore

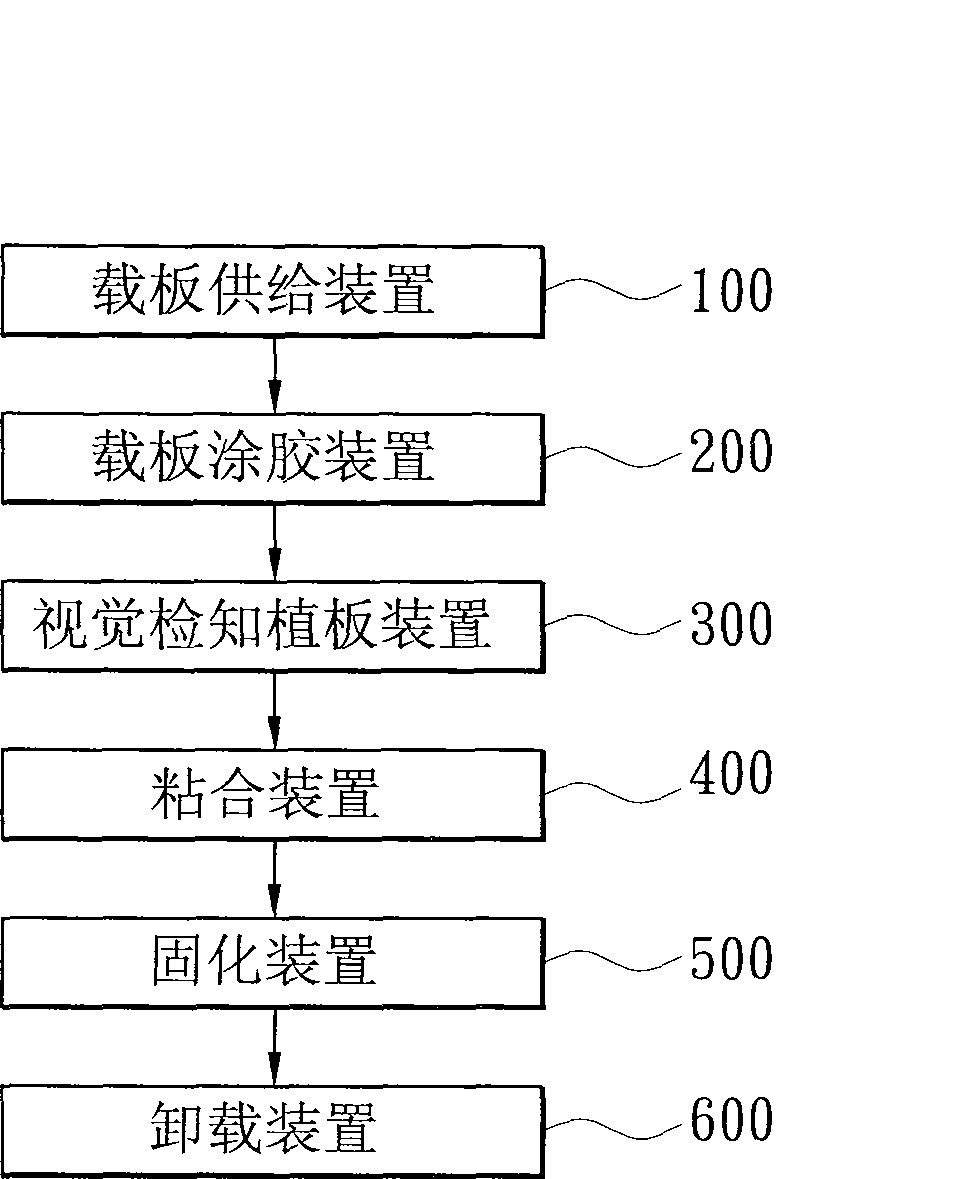

A detection and vision technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inability to operate, increase costs, and position errors, and achieve the effects of saving production costs, increasing production capacity, and increasing pass rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

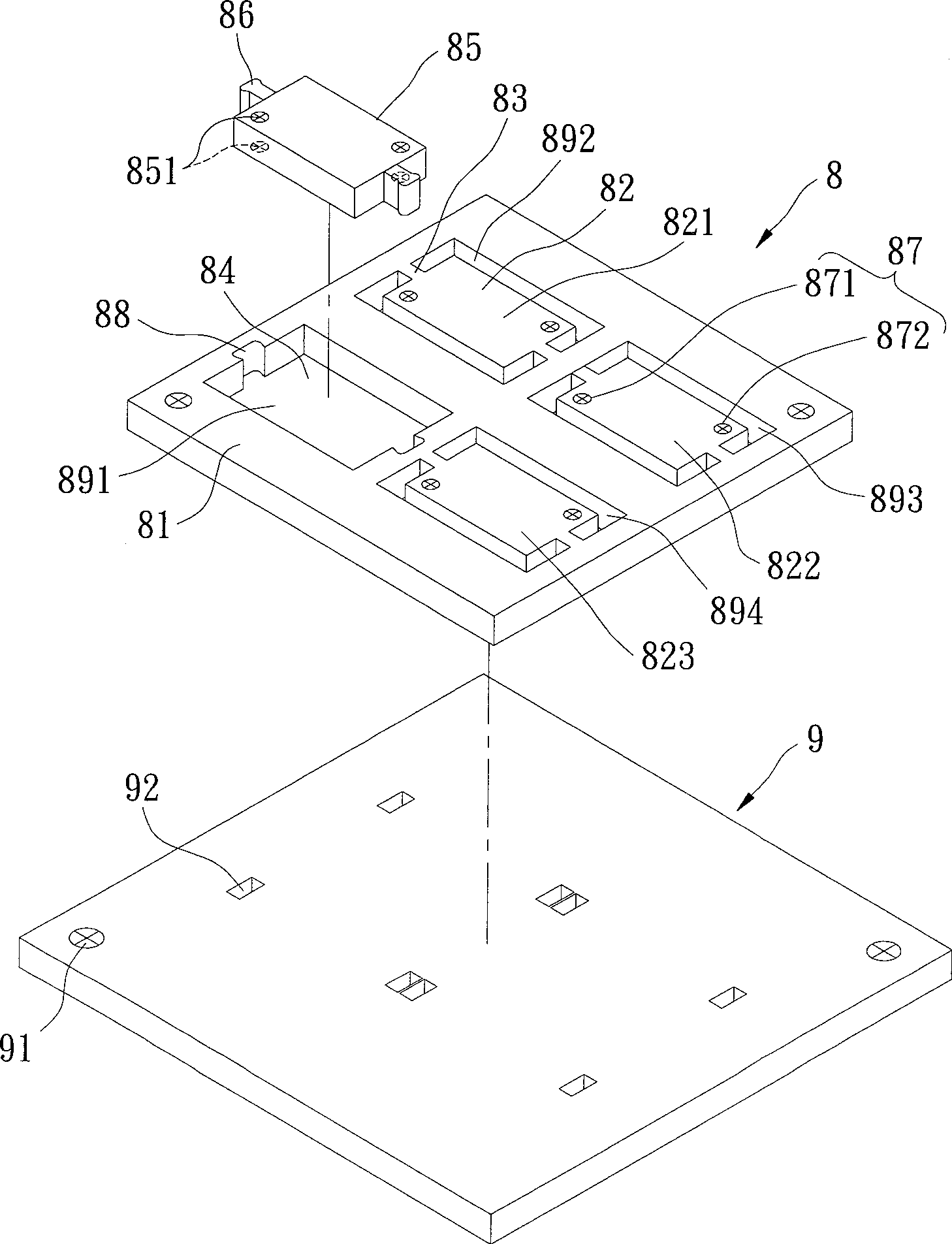

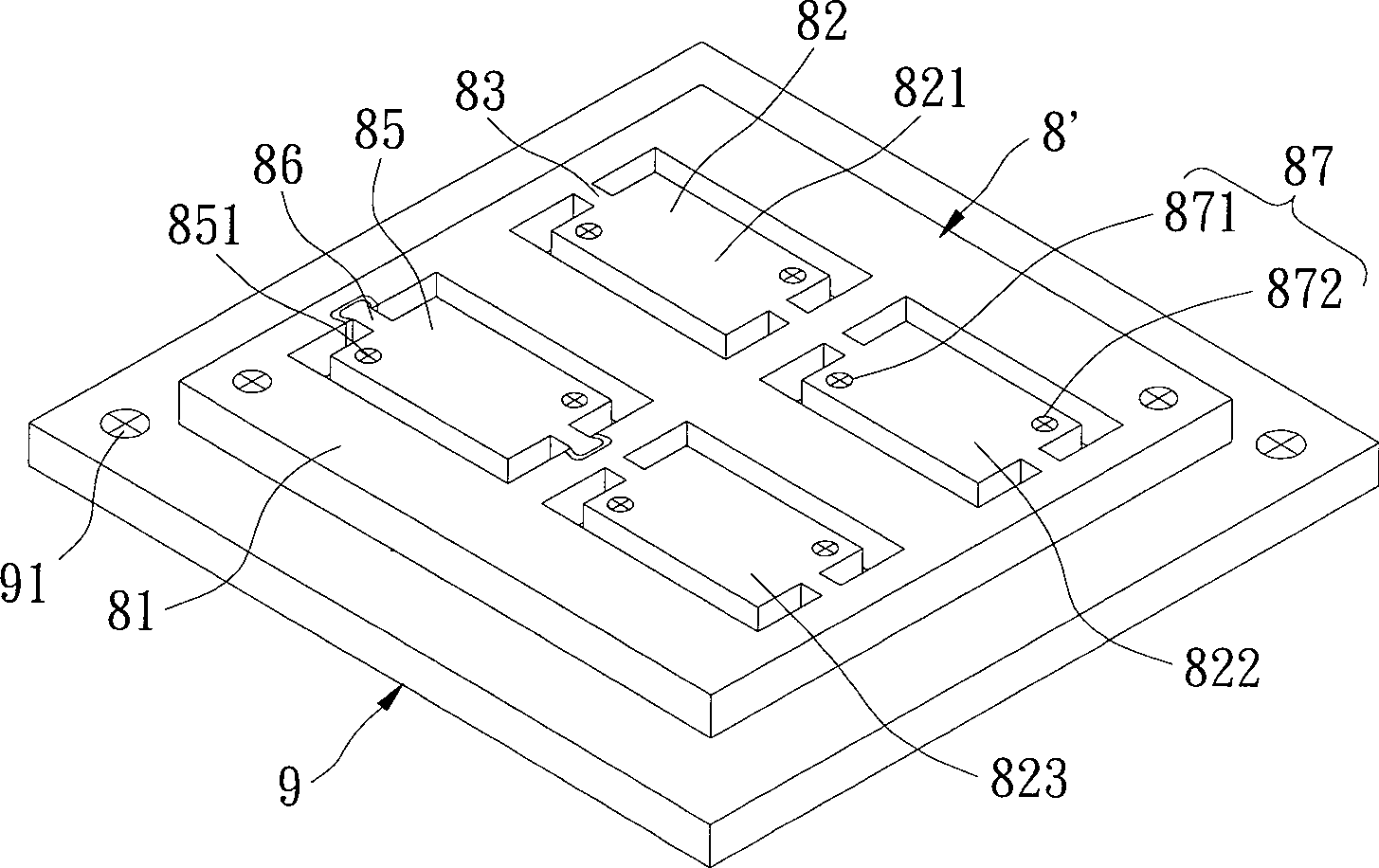

[0107] Please refer to Figure 4 , which is the first embodiment of the carrier board gluing device 200 of the present invention, the carrier board gluing device 200 includes a frame body 11 , a transport device 12 , and an adhesive coating device 13 .

[0108] The transportation device 12 is installed on the frame body 11 , and it can be a conveyor belt, a robot arm or other devices with transportation capabilities, which are used to transfer the carrier board 9 .

[0109] The viscose coating device 13 is arranged on the frame body 11, and it can be erected on one side of the frame body 11 parallel to the transportation device 12, and the viscose coating device 13 can extend along the side of the transportation device 12 parallel to the transportation device 12. The side moves horizontally, and the viscose coating device 13 includes a cantilever 131, which has a telescopic function. The component 132 can control the coating amount of glue, so as to coat the glue on the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com