Novel method for preparing hafnium acetylacetonate

A technology of acetylacetone and hafnium acetone dimer, which is applied in the preparation of aldehyde/ketone chelate, organic chemistry, etc., to achieve high yield, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

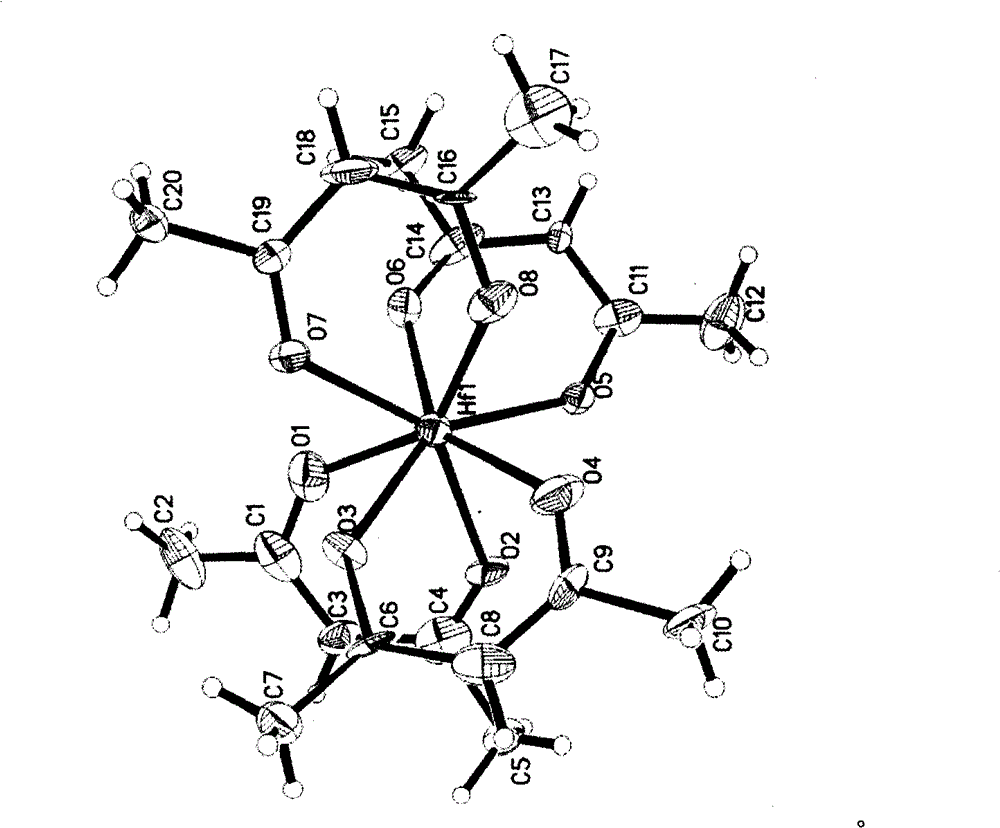

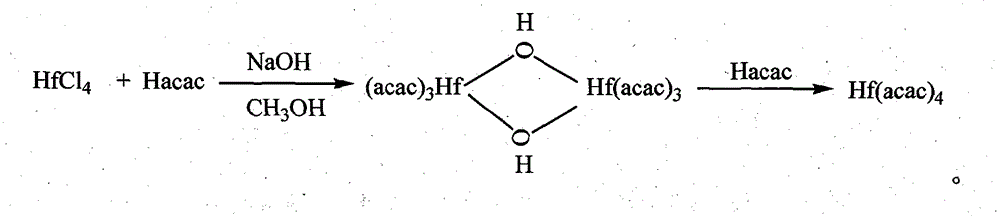

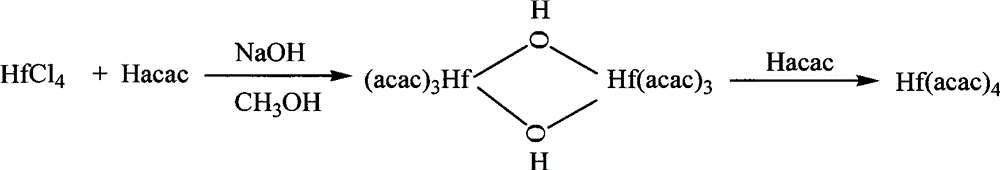

[0010] 1. Hafnium acetylacetonate dimer Hf containing hydroxyl bridge 2 (OH) 2 (acac) 6 Preparation

[0011] Weigh 40.0g anhydrous HfCl 4 Dissolve in 250ml methanol, transfer to a 1000ml reaction flask, add 74ml Hacac, adjust the pH value between 6-9 with NaOH, if necessary, use Hacac to reverse-adjust, and react at 60℃ for 5h, filter to remove the precipitate, change the reaction solution Concentrate to dryness to obtain hafnium acetylacetonate dimer Hf containing hydroxyl bridge bond 2 (OH) 2 (acac) 6 60.27g, the yield is 98%.

[0012] Hf 2 (OH) 2 (acac) 6 The characteristic structure parameters of the element: (1) Elemental analysis C 36.47% H 4.43% Hf 36.47% is consistent with the theoretical value C 36.51% H 4.46% Hf 36.20%; (2) FAB + -MS m / e=987(C 30 H 44 O 14 Hf·H + , 45%); (3) IR(cm -1 , KBr tablet) 3437 (s, v O-H), 1529 ~ 1595 (s, vC = O), 540 ~ 565 (m, vHf-O); (4) 13 C(dmso, ppm) 188.0, 102.5, 26.7; (5) 1 HNMR(CDCL 3 , Ppm) 5.5 (s, 1H, CH), 4.1 (s, 1H, OH), 1.97 (s, 6H, 2C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com