Preheating method for residual oil raw material on bubbling bed

A fluidized bed and raw material technology, which is applied in the field of preheating of inferior residue oil, can solve the problems that the outlet stream temperature of the heating furnace cannot be guaranteed, the performance of the fluidized bed hydrogenation reaction is affected, and the long-term stable operation of the device is affected, and the temperature requirement can be guaranteed. indicators, avoid condensation and coking reactions, and reduce processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

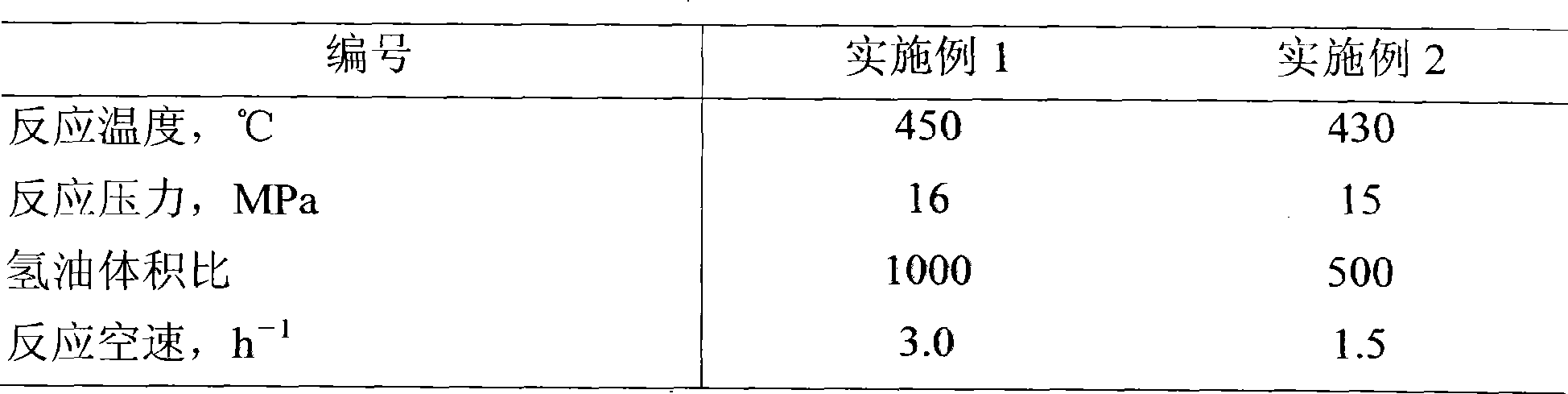

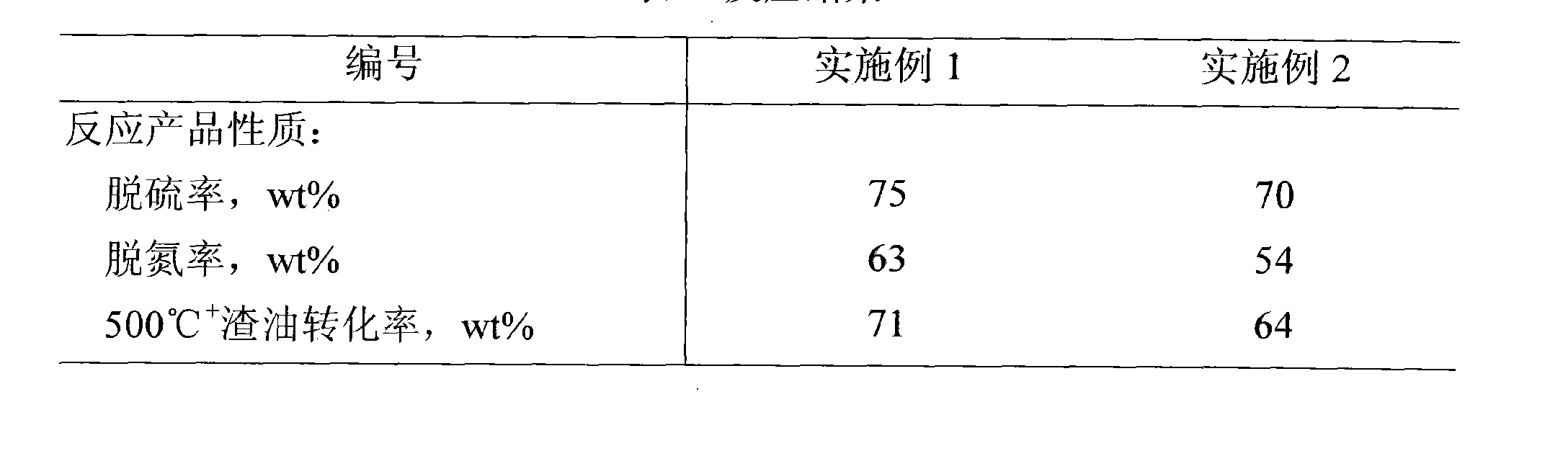

Embodiment 1

[0032]This example is an example of using a moving-bed preheating reactor to preheat residual oil. The specific process is as follows: a spent diesel hydrogenation catalyst (spherical, with a particle size of 0.6mm) heated to 600°C by a heating furnace and preheated The mixture of residual oil raw material heated to 300°C and hydrogen (wherein hydrogen accounts for 30% of the residual oil raw material volume) enters from the solid feed line and raw material feed line at the top of the moving bed preheating reactor respectively, wherein the hot solid matter is fed by Gravity is added, and the weight ratio of solid matter and residual oil raw material is 4.3, and the contact heat exchange time of raw material and hot solid matter in container is 30 minutes, and the flow outflow temperature of control preheating reactor outlet is 450 ℃, gauge pressure is 0.3MPa. The raw material flow after heat exchange is discharged from the middle and lower part of the container and enters the ...

Embodiment 2

[0035] This example is an example of using batch operation to preheat ebullated bed feed, using an empty cylinder reactor, and the specific process is: in the heating furnace, the waste residue oil hydrodenitrogenation catalyst (with a particle size of 0.8-1.1mm) Heating to 650°C, and then transporting it to the container by gravity from the top of the preheating reactor; then injecting the residual oil preheated to 250°C and hydrogen gas (wherein hydrogen accounts for 15% of the residual oil raw material volume) In the preheating reactor, it contacts with hot solid matter to exchange heat; wherein the weight ratio of waste catalyst to residual oil raw material is 3.5, the outflow temperature of the stream at the outlet of the preheating reactor is controlled to be 430°C, the operating pressure is normal pressure, and the reaction time is 50 minutes. The solid matter is not discharged from the reactor, and is directly heated by the method of oxidizing and burning charcoal in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com