Foundation pit supporting method with double rows of piles

A technology of foundation pit support and double-row piles, which is applied in the field of foundation foundation, can solve the problems of small excavable depth of foundation pit, deformation of the ground outside the foundation pit, and endangering the surrounding environment, so as to reduce the reinforcement amount of the pile body, The effect of increased excavation depth and good technical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

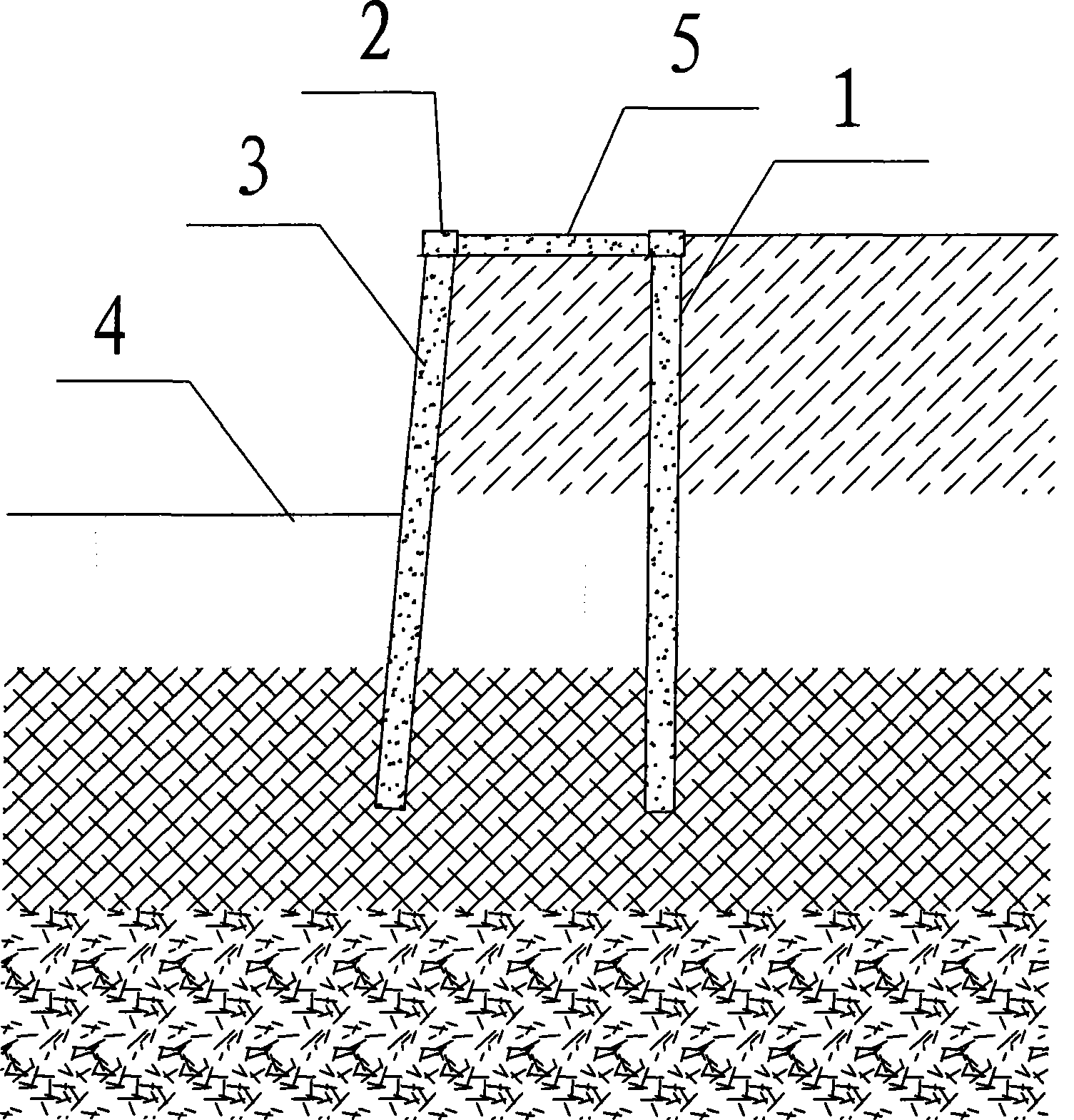

Image

Examples

Embodiment 1

[0029] The rectangular foundation pit of an office building is 75.0m long, 18.0m wide, and the excavation depth is 9.120m. The geotechnical engineering investigation report shows that the range from the ground to the buried depth of 2.4m is miscellaneous fill, and the range from the buried depth of 2.4m to the buried depth of 16.5m Inside is silt. There are no important buildings around the construction site of the foundation pit project, and the supporting structure adopts double rows of piles with the front row of piles inclined. The inclination of the front row of inclined piles is 15°, the length of the supporting piles is 21m, the diameter of the piles is 800mm, and the distance between piles is 100mm. The construction method of hanging prefabricated piles is adopted. The vertical piles in the back row are 18m long, 800mm in pile diameter, and 100mm in pile distance, and the construction method of hanging and driving prefabricated piles is adopted. The distance between t...

Embodiment 2

[0031] The excavation project of a subway station is 230.0m long, 22.4m wide, and the excavation depth is 16.370m. Double-row piles with inclined front piles are used on both sides of the long side, and the two ends are blocked in advance by underground diaphragm walls.

[0032] The vertical distribution of strata within the excavation depth range of the foundation pit from top to bottom is: fill soil, thickness 2.70-4.50m; ②silt, thickness 8.10-13.00m; ③coarse gravel sand, thickness 1.0-8.0m; ④silty Clay, thickness 0.18-2.80m; ⑤ residual sandy cohesive soil, thickness 1.40-13.10m; ⑥ fully weathered granite, thickness 0.85-7.85m; ⑦-1 sandy strongly weathered granite, thickness 0.40-14.50m; ⑦-2 Fragmented strongly weathered granite, with a thickness of 1.0-3.9m; ⑧medium weathered granite, with a thickness of 1.10-12.20m; ⑨slightly weathered granite.

[0033] The support structure adopts a double row of piles with the front row of piles inclined. The inclination of the front r...

Embodiment 3

[0035] A circular foundation pit with a diameter of 137 meters and a depth of 14.150 meters is used for foundation pit support with a double row of piles with an inclined front row of piles. The ground elevation of the foundation pit site is 2.367 meters above sea level, the range from the ground to the elevation -18 meters is miscellaneous fill and silt, the elevation -18 meters to the elevation -27 meters is silty clay, and the soil quality is good. Tube wells are arranged in the foundation pit for dewatering and dewatering.

[0036] The supporting structure of the foundation pit adopts a double row of piles with the front row of piles inclined. The inclination angle of the front row of piles is 1°, the length of the supporting piles is 31m, the diameter of the piles is 800mm, and the center distance of the bottom of the piles is 850mm. The vertical piles in the back row are 29m long, 800mm in pile diameter, and 100mm in pile distance. They are drilled and poured into piles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com