Tetra-piston type air pump

An air pump, piston type technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problems of small exhaust flow and low working efficiency of the air pump, and achieve the effect of enhancing the ability to transport gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

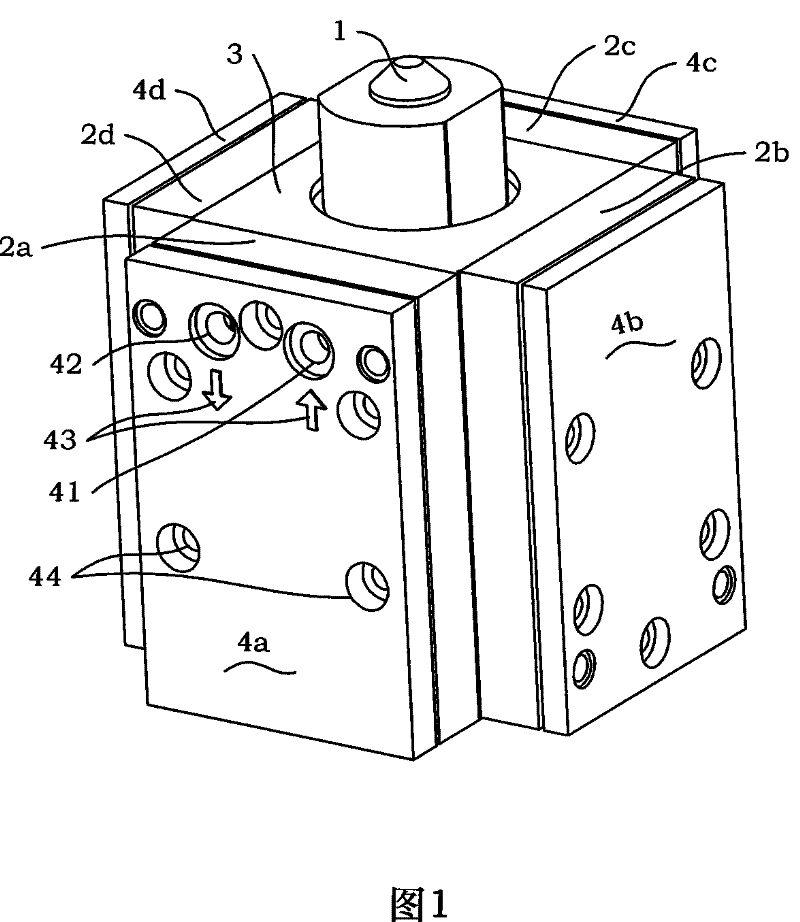

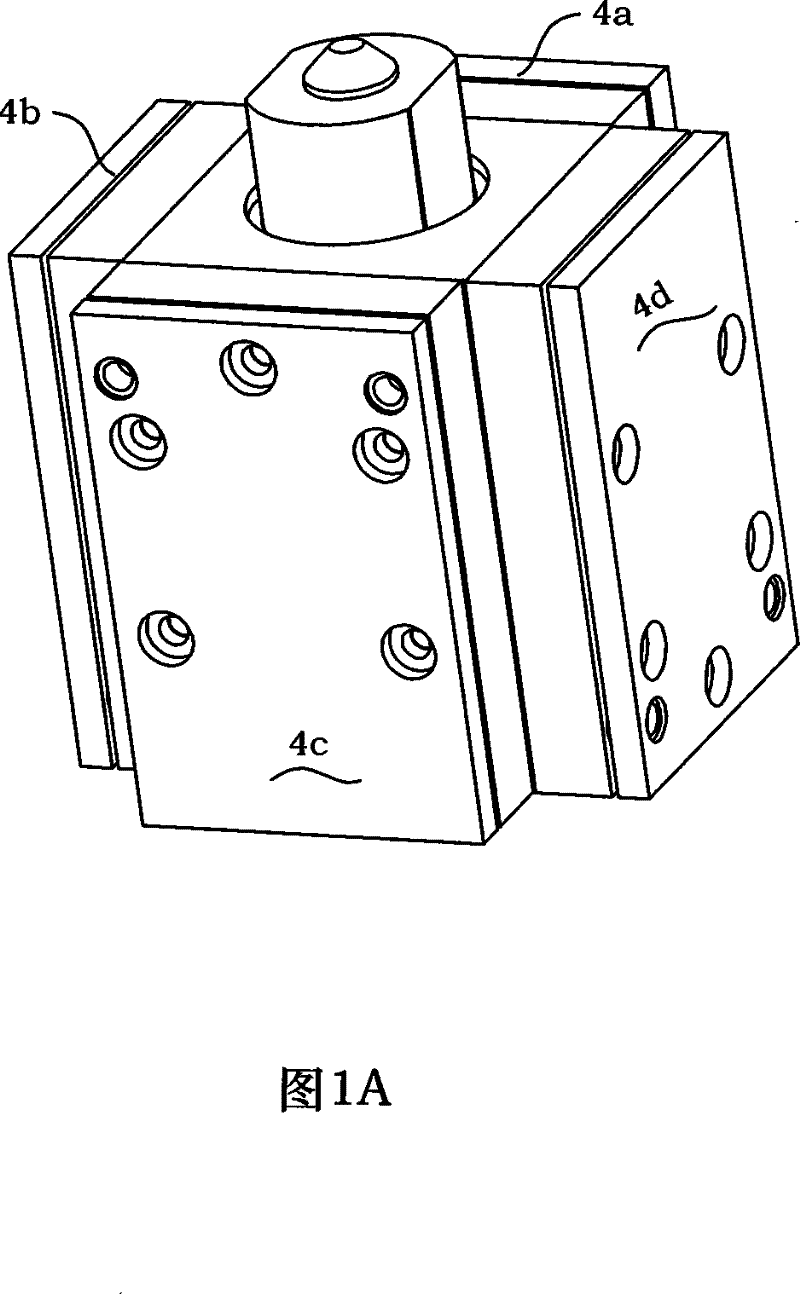

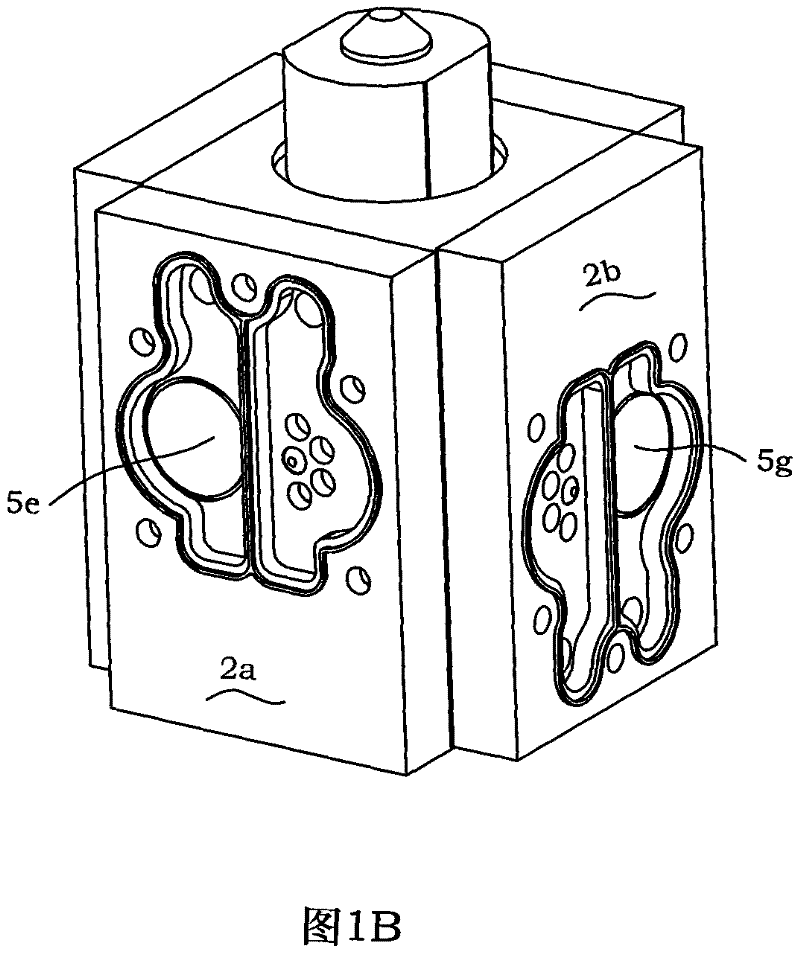

[0022] see figure 1 , Figure 1A ~ Figure 1E , figure 2 Shown, the present invention is a kind of four-piston air pump that has motor to rotate one week, has four suctions, four exhausts, and this air pump includes four cover plates (A cover plate 4a, B cover plate 4b, C cover plate 4c, D cover plate 4d), four air guide plates (A air guide plate 2a, B air guide plate 2b, C air guide plate 2c, D air guide plate 2d), power assembly 1, pump body 3, And multiple diaphragms for air intake and exhaust. The power assembly 1 is installed in the motor installation hole 35a of the pump body 3, the four air guide plates are respectively fitted and assembled on the four mounting surfaces of the pump body 3, and the four cover plates are respectively fitted and assembled on the four air guide plates .

[0023] see figure 2 , Figure 2A As shown, the power assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com