Heat exchange method of pipe shell type heat-exchanger and heat exchanger thereof

A shell-and-tube heat exchanger, heat method technology, applied in indirect heat exchangers, heat exchanger types, evaporators/condensers, etc., to save costs, reduce fouling deposits, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

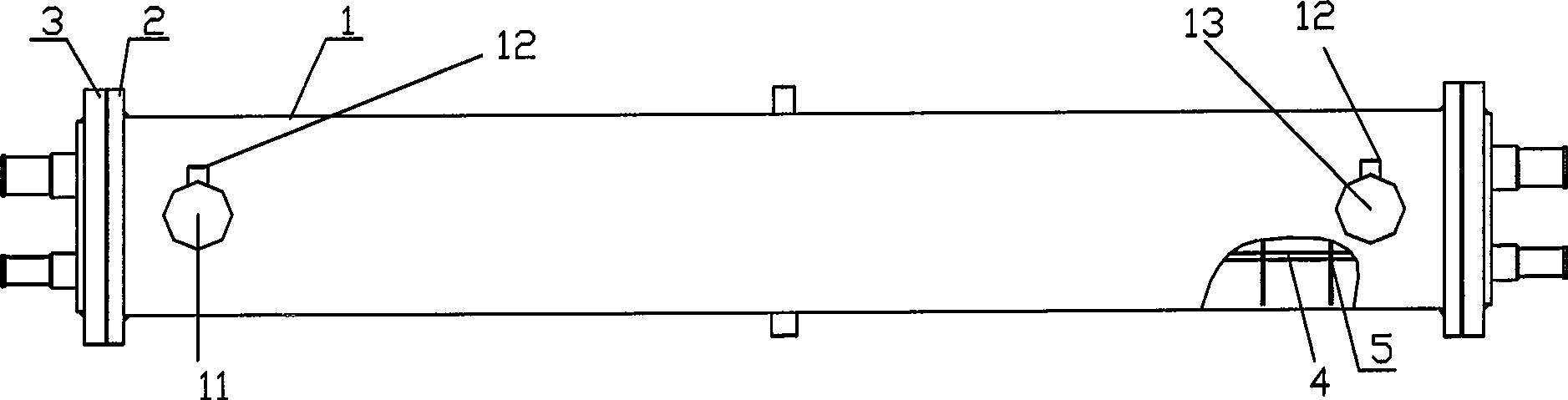

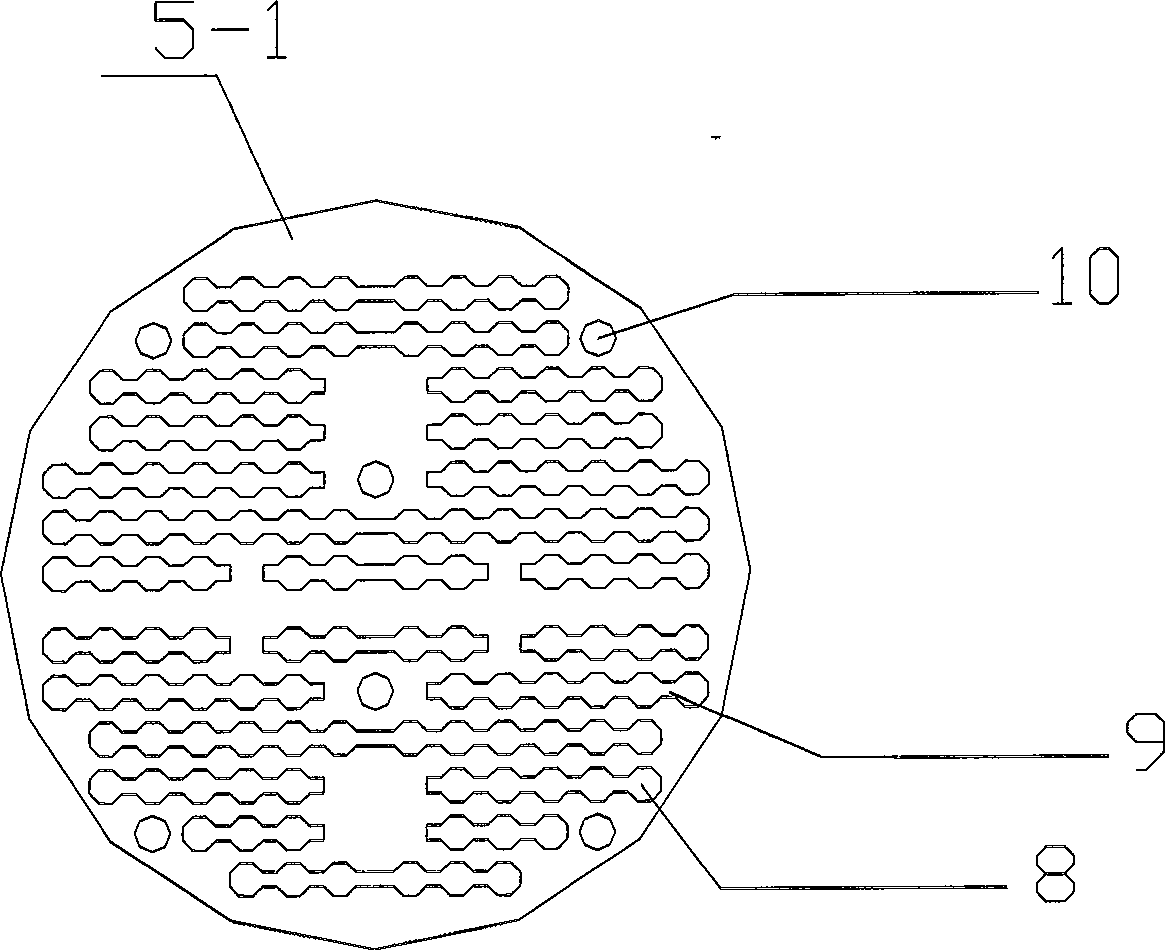

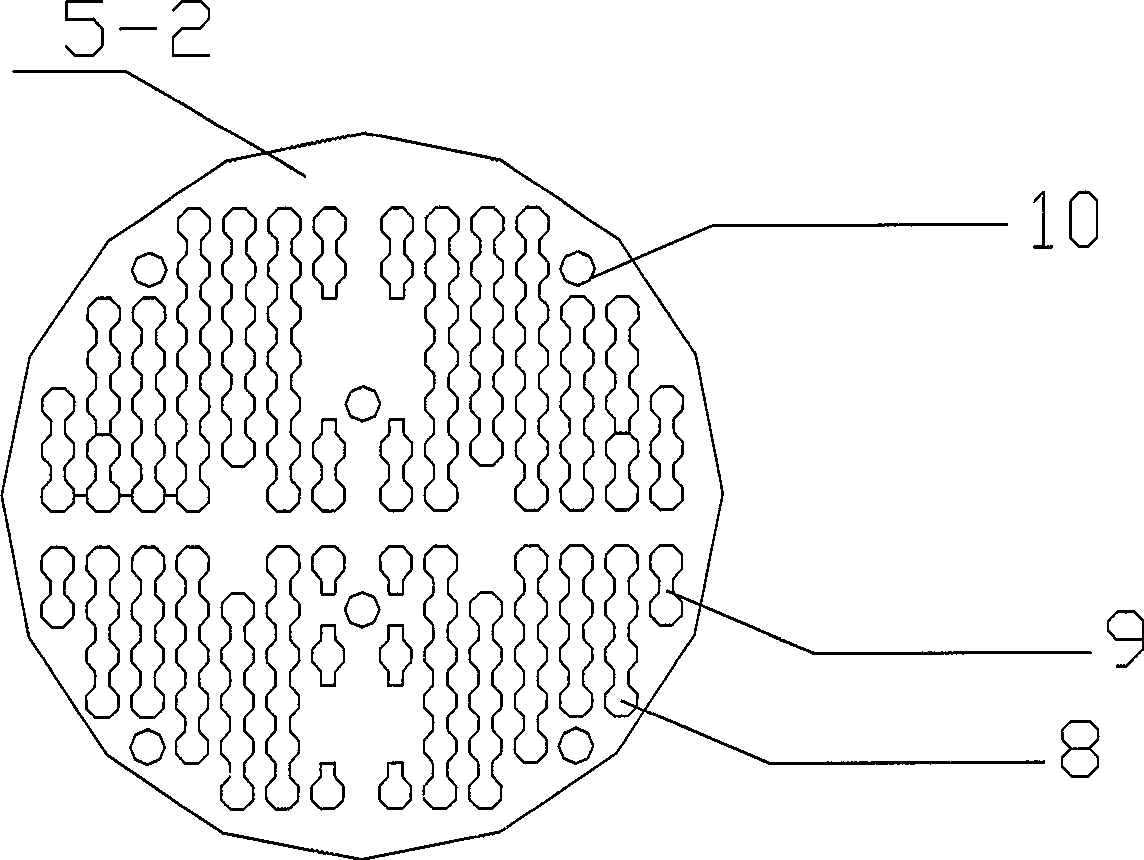

[0030] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

[0031] A heat exchange method for a shell-and-tube heat exchanger. The method uses the shell-and-tube heat exchanger for heat exchange. The inner channel of the heat exchange tube supported by a baffle is used as the tube side, and the outer channel of the heat exchange tube is used as the shell. The tube-side fluid and the shell-side fluid exchange heat in the shell, the flow direction of the shell-side fluid is the same as the axial direction of the heat exchange tube, and the included angle between the flow direction of the shell-side fluid and the tube-side fluid can be 0° or 180° .

[0032] The shell-side fluid of the present invention flows and advances in a spiral manner around the tube wall of the heat exchange tube. In this way, the short-circuit shunt phenomenon formed by the shell-side fluid in the shell is avoided, the heat exchange area is eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com