Cylindricity non-contact measurement method and system based on multi-diameter splicing technology

A non-contact measurement and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effects of convenient operation, good application value, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

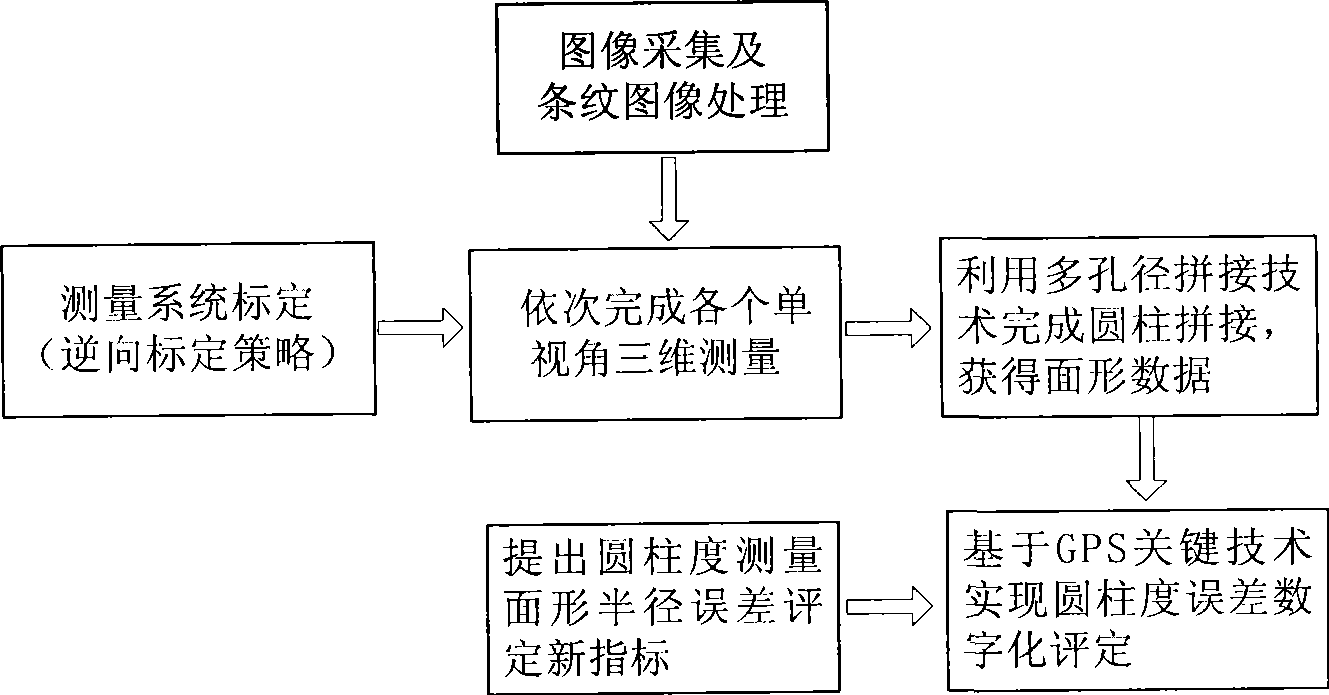

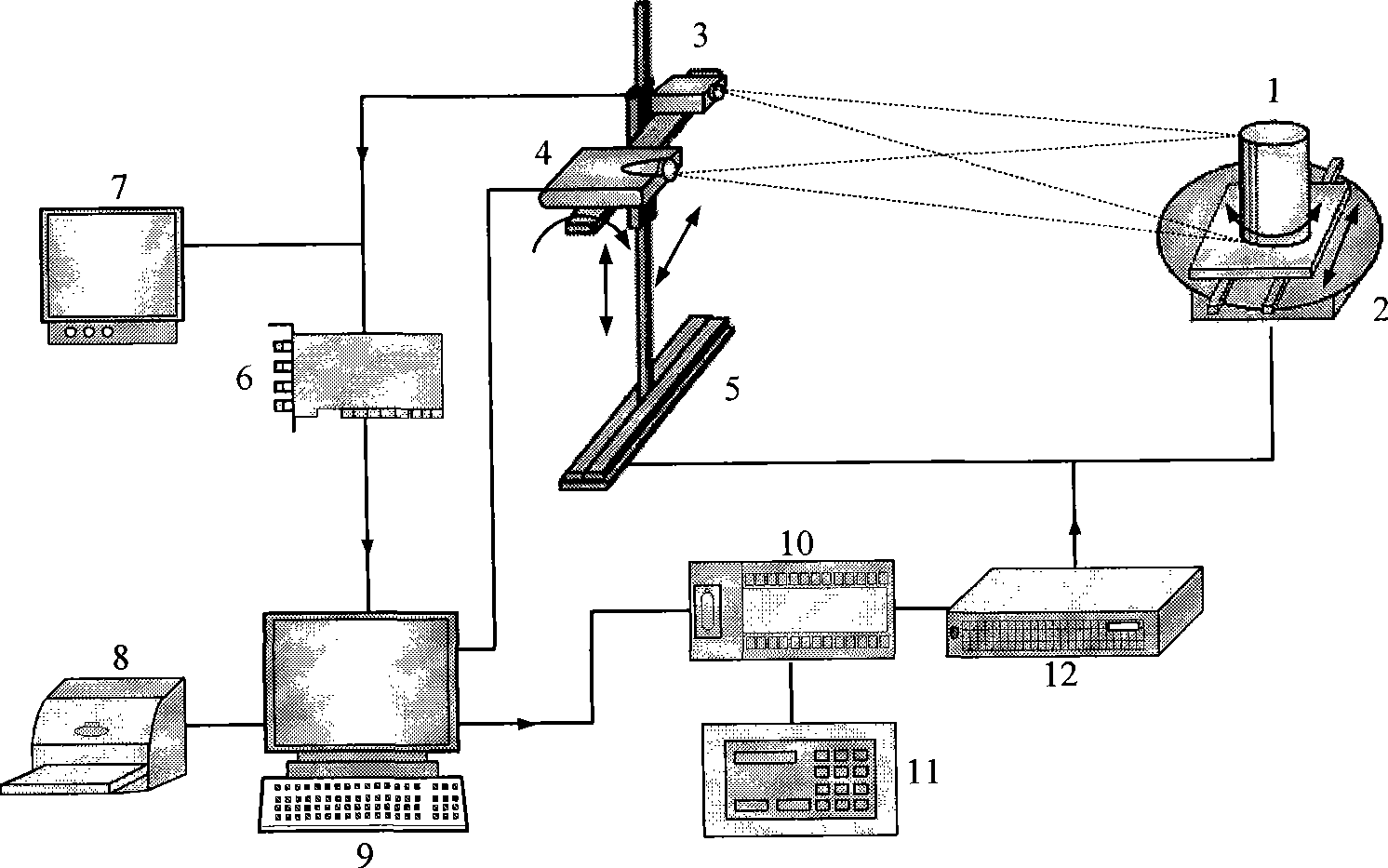

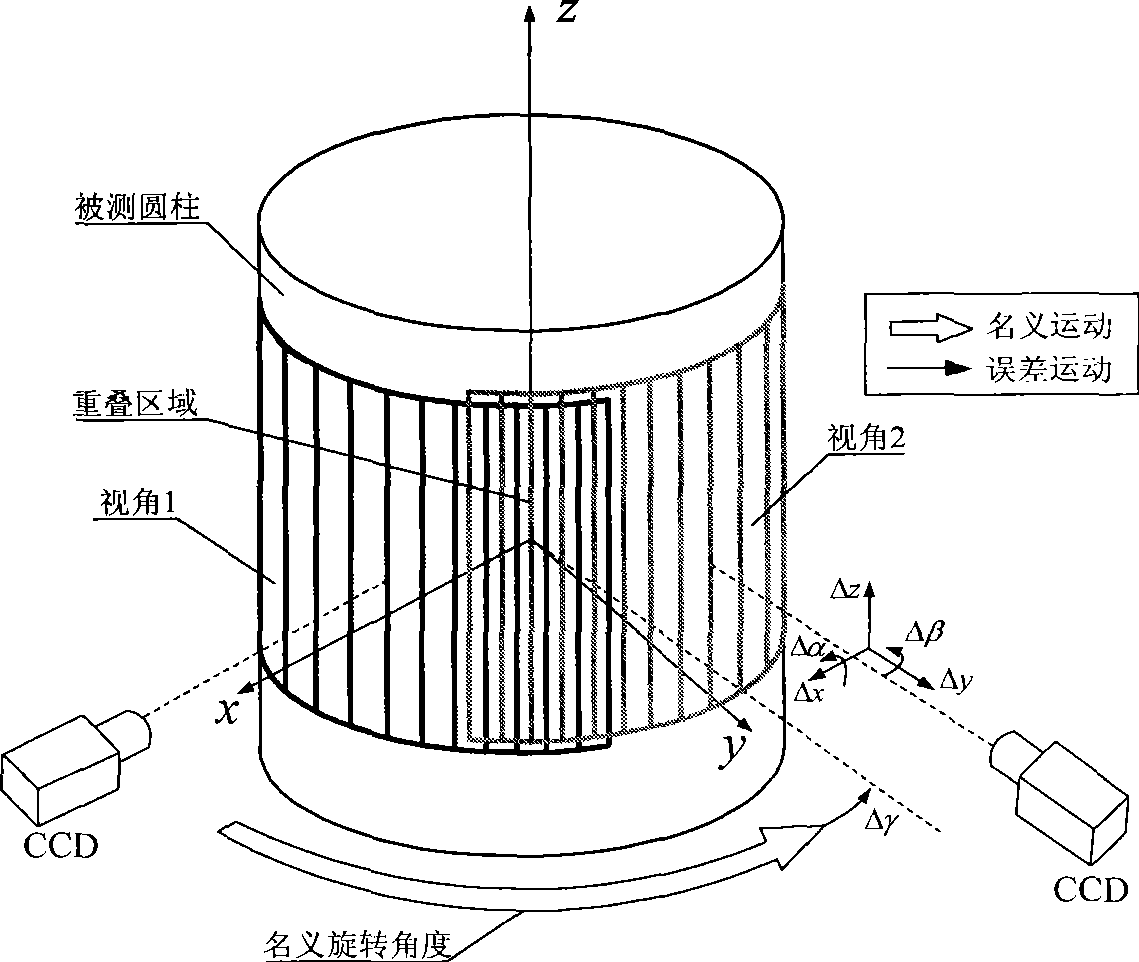

[0023] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: See figure 1 , a non-contact measurement method of cylindricity based on multi-aperture splicing technology. First, the measurement system is calibrated, followed by image acquisition and fringe image processing, and overlapping scanning is performed by controlling the relative motion of the two-dimensional image sensor and the measured cylinder , and sequentially obtain multiple single-view surface data of the measured cylinder; secondly, based on the multi-aperture splicing and fusion technology to realize the accurate splicing of multi-view surface data, and obtain the overall cylindrical surface data; furthermore, according to the geometric product technical specification GPS key The technical design inspection operation operator realizes the digital evaluation of cylindricity, and puts forward the evaluation index of cylindricity measurement surface radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com