Clamping device

一种夹持装置、夹持的技术,应用在测量装置、夹钳、服饰等方向,能够解决工件变形、影响检测结果准确性、很难把握力度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

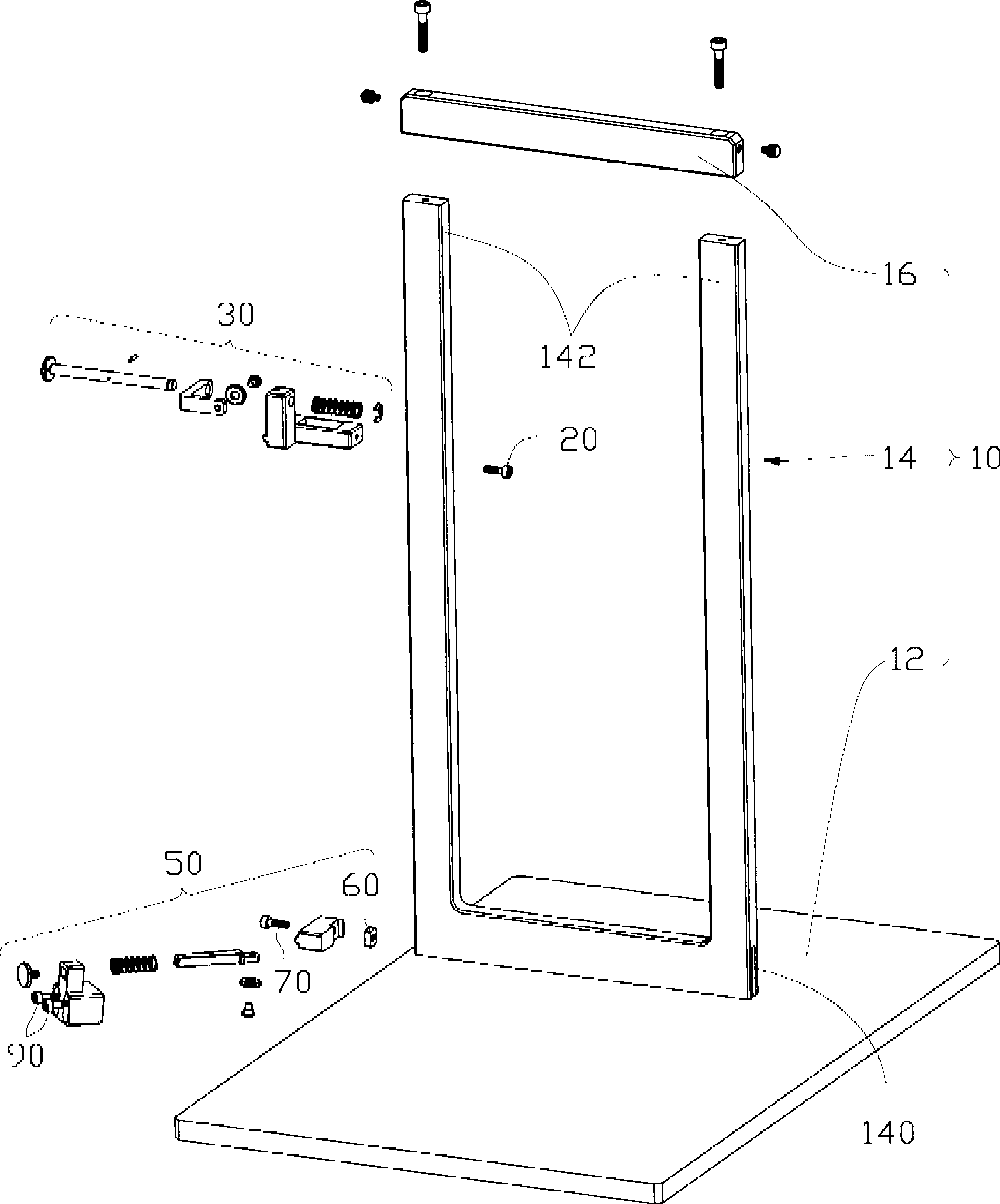

[0013] Please refer to figure 1 , a preferred embodiment of the clamping device of the present invention, which includes an operating frame 10 , a first clamping part 30 and a second clamping part 50 .

[0014] The operating frame 10 includes a platform 12 , a “U”-shaped bracket 14 vertically installed on the platform 12 and a beam 16 connecting the upper end of the bracket 14 . The bracket 14 includes two vertically parallel supporting arms 142 , and a sliding slot 140 is respectively provided on the sides of the two supporting arms 142 adjacent to the platform 12 .

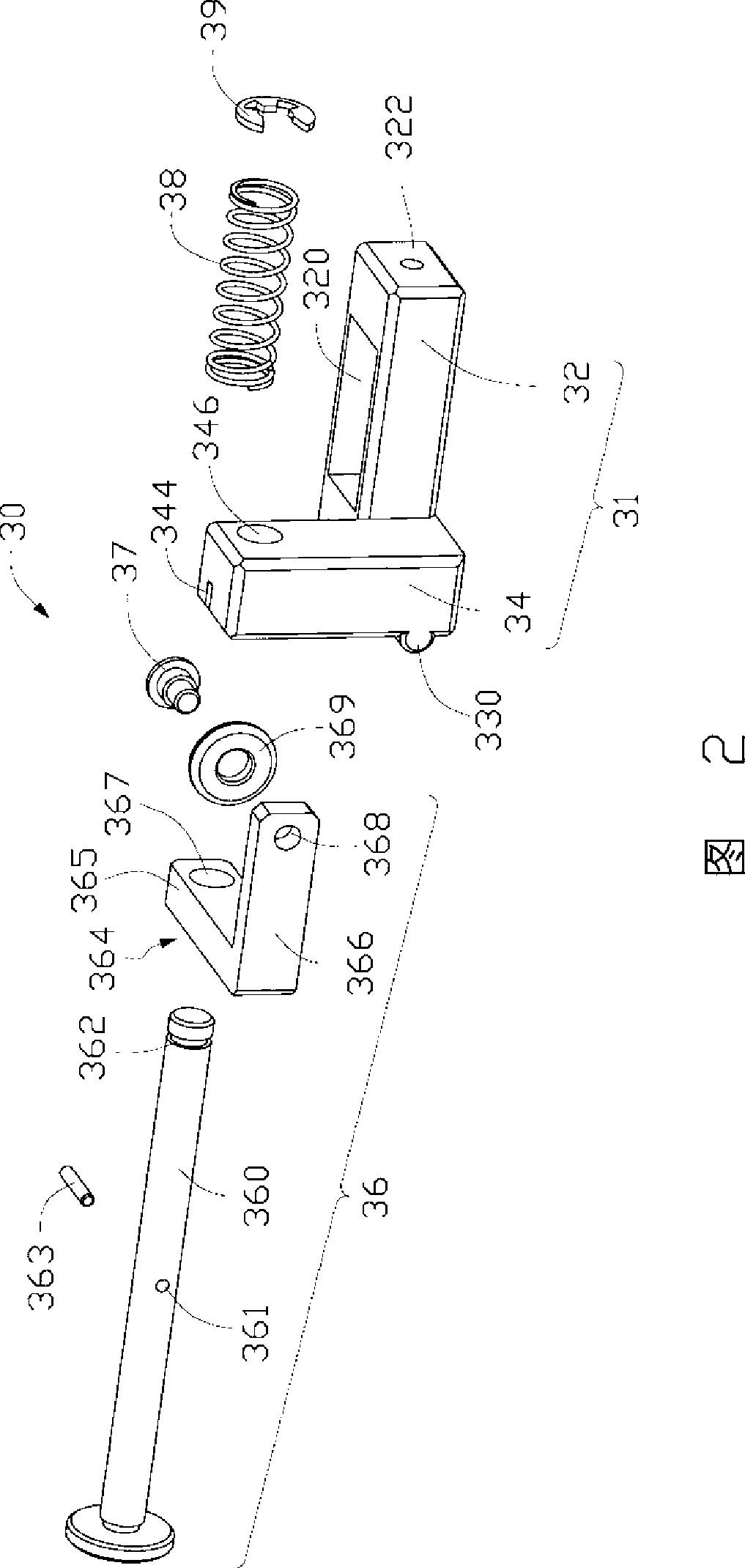

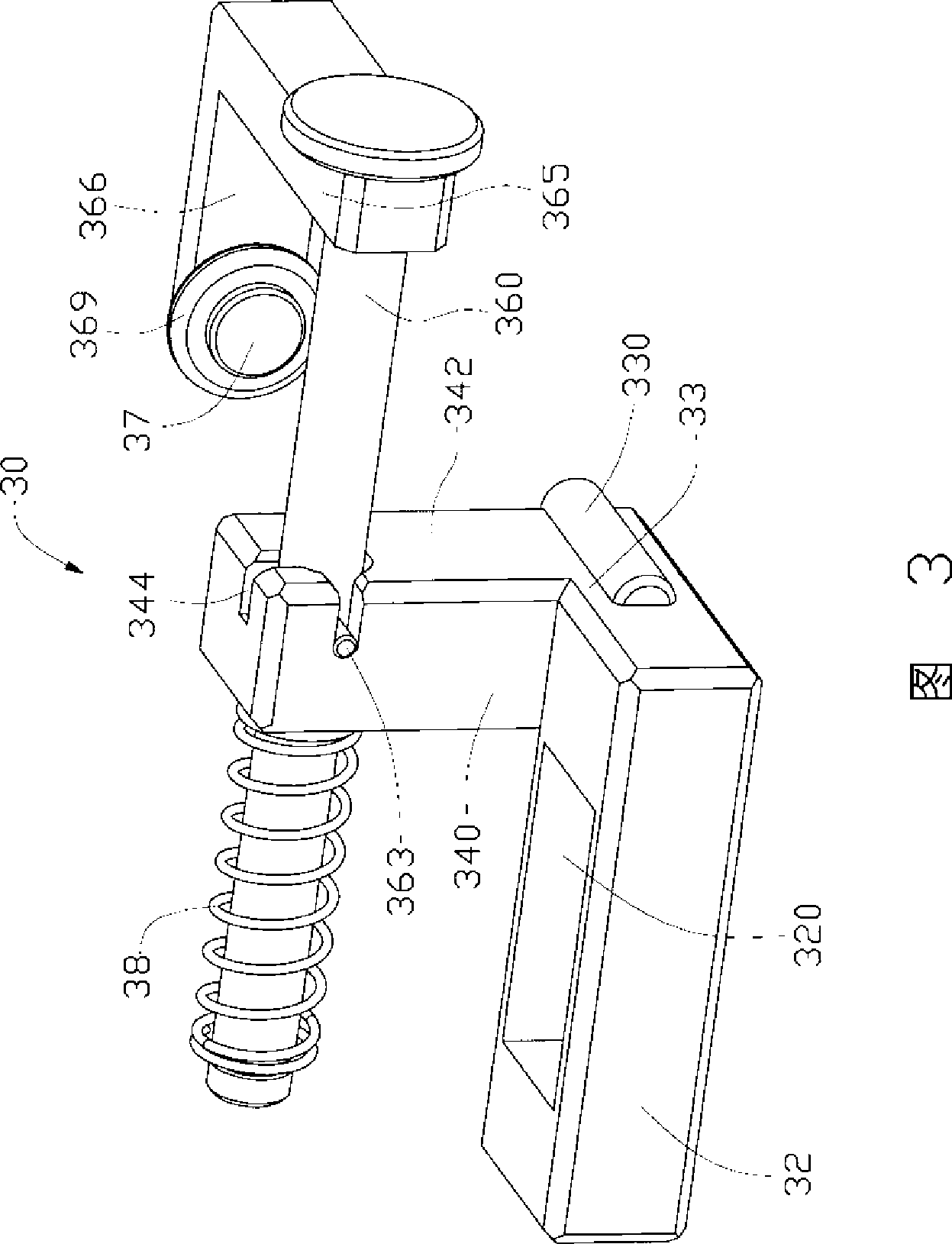

[0015] Please refer to FIG. 2 and FIG. 3 together. Please refer to FIG. 2 and FIG. 3 together. The first clamping member 30 includes a positioning member 31 , a clamping portion 36 and a spring 38 . The positioning member 31 includes a horizontal rectangular sliding portion 32 , and a vertical rectangular locking portion 34 located at one side and one end of the sliding portion 32 . A rectangular through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com