Direct image exposure device

An exposure device and image technology, which can be used in photolithography process exposure devices, microlithography exposure equipment, optics, etc., and can solve the problems of complex and expensive devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

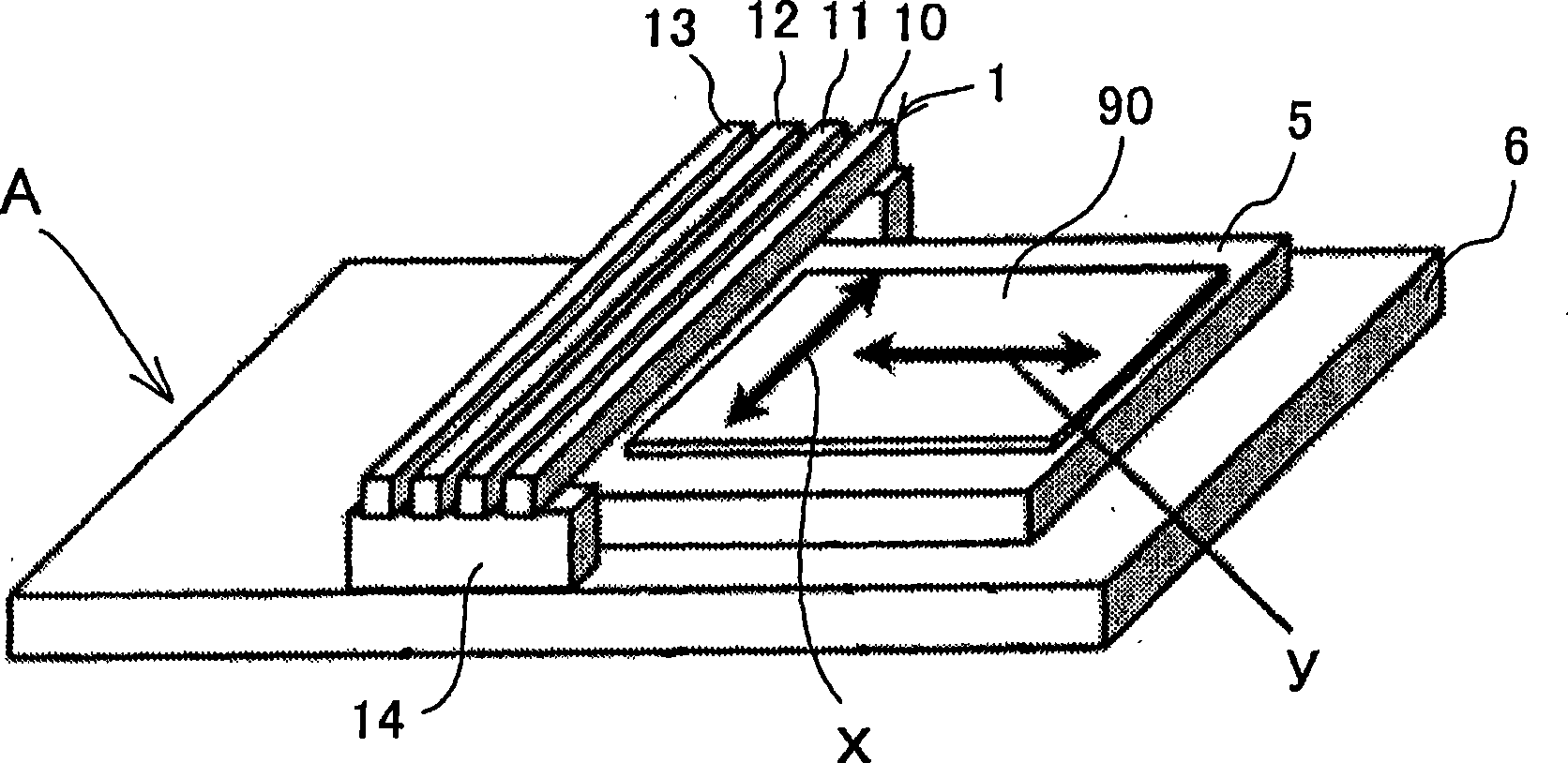

[0032] The present invention will now be described with reference to the accompanying drawings. figure 1 and 2 An embodiment of the direct image exposure of the present invention is shown.

[0033] The direct image exposure apparatus A has a base 6 on which the exposure head assembly 1 is disposed along the main scanning direction X, and a printed circuit board 90 on the exposure table 5 is disposed movable in the sub scanning direction Y.

[0034] The main scan of direct image exposure is performed by switching the illuminants such as LEDs of the exposure head assembly 1 , and the sub scan is performed by moving the exposure table 5 .

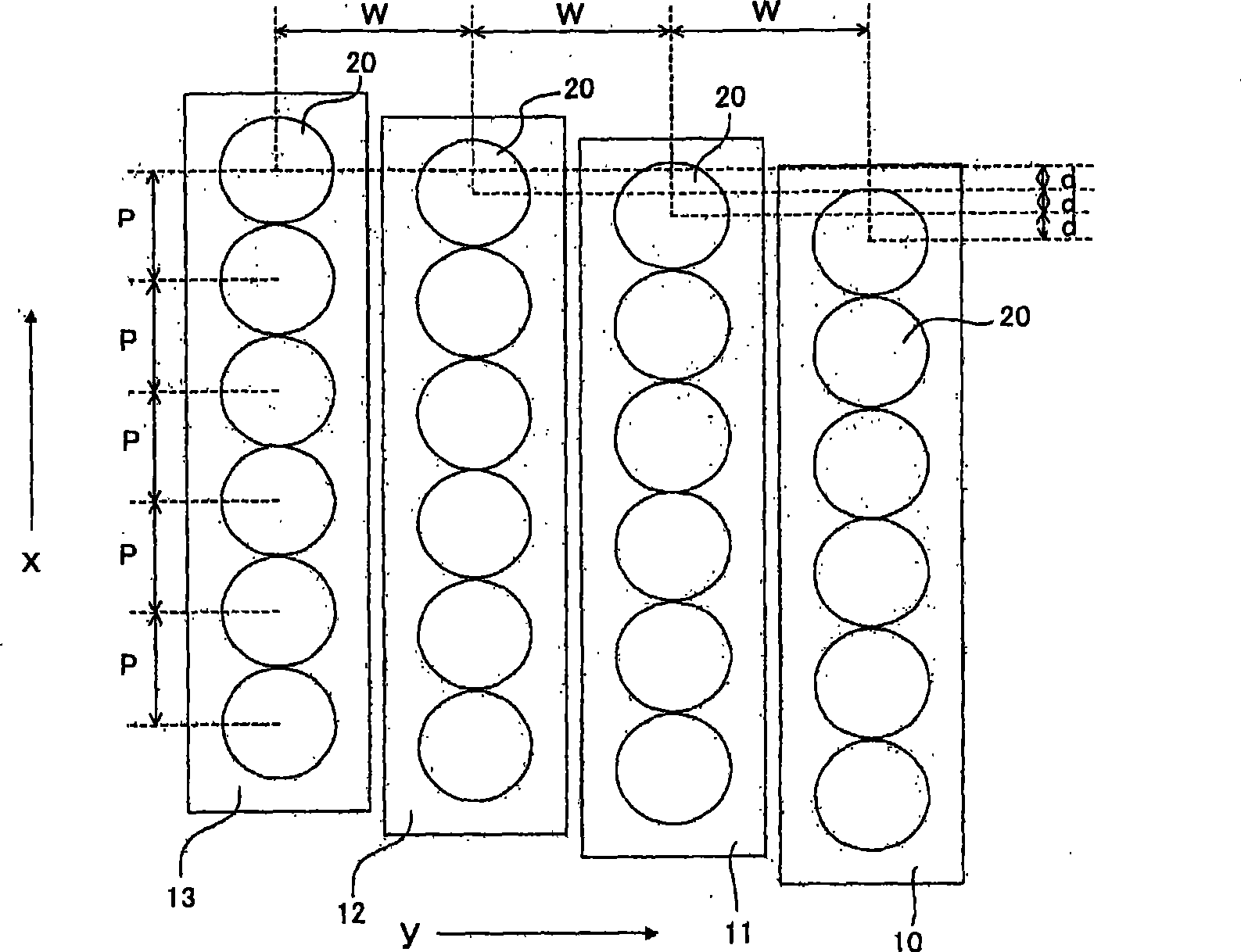

[0035] The exposure head assembly 1 has a plurality of exposure heads 10 , 11 , 12 , 13 . Although four exposure heads 10, 11, 12, 13 are provided in the present embodiment, the number can be changed as necessary.

[0036] The respective exposure heads 10 , 11 , 12 , 13 are arranged along the main scanning direction X, and the exposure head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com