Production line real time acquiring and data accounting system and method

A statistical data and real-time collection technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as increased manpower input, increased data distortion, and human statistical errors, so as to save labor costs and reduce errors , the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

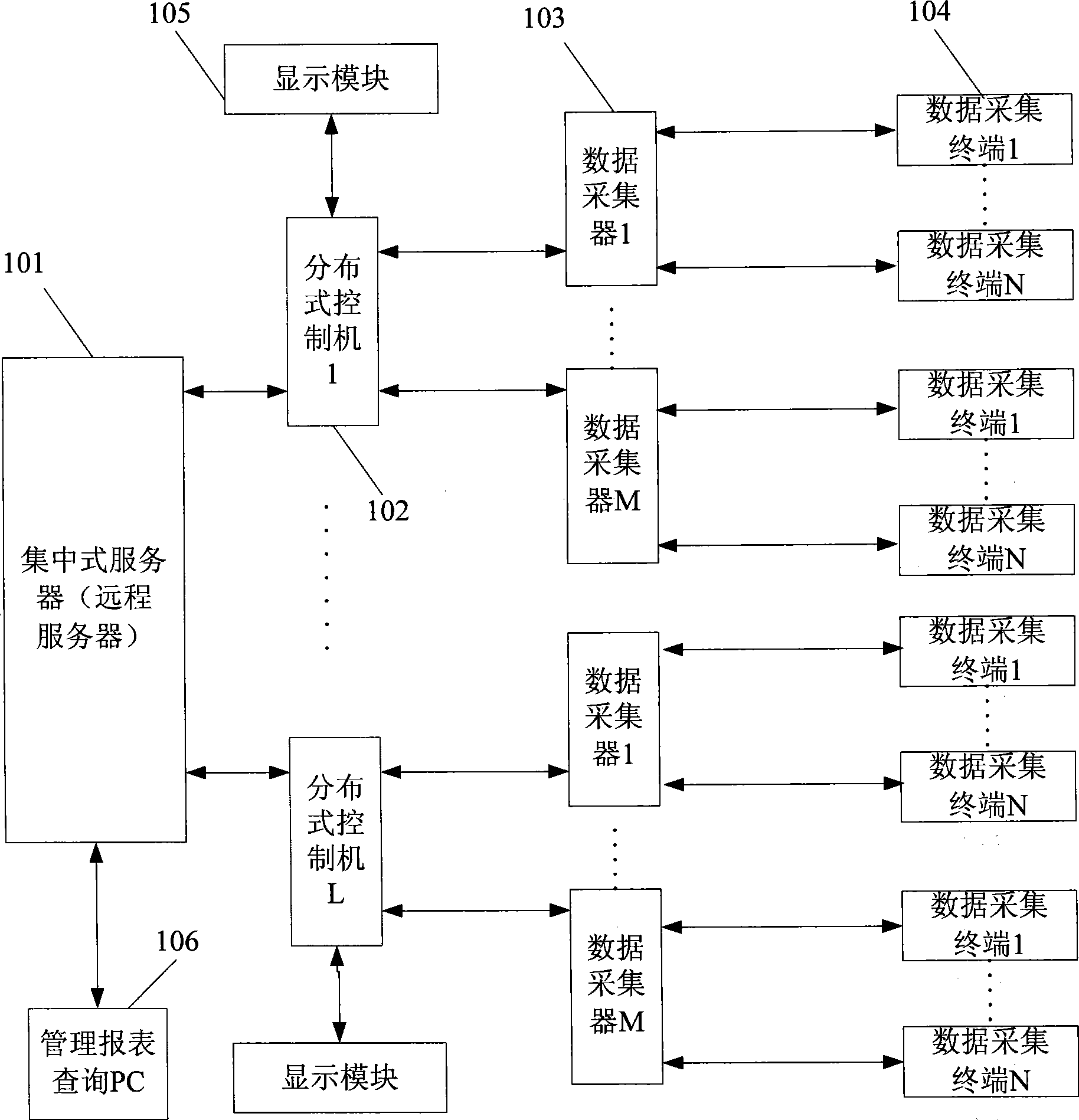

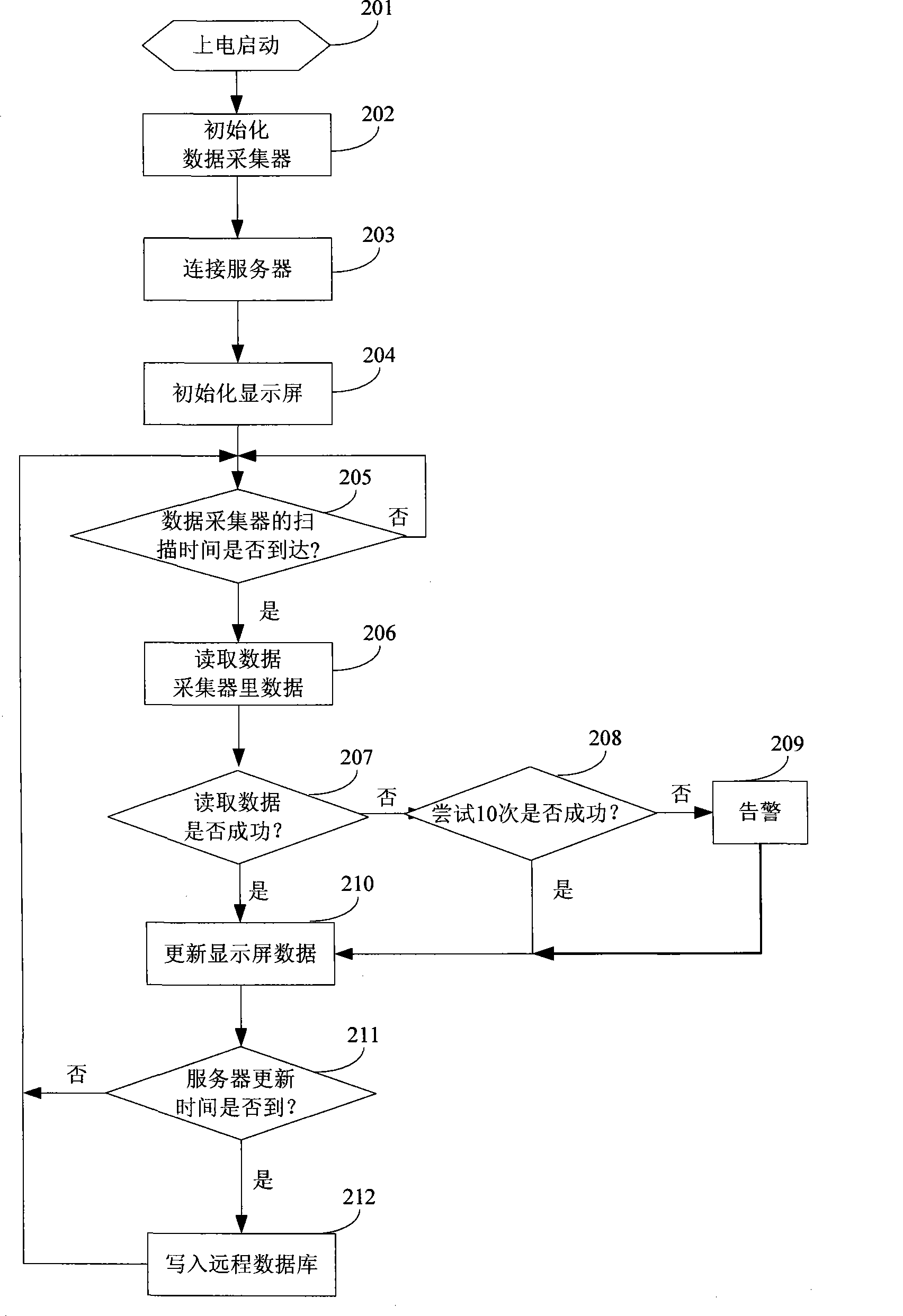

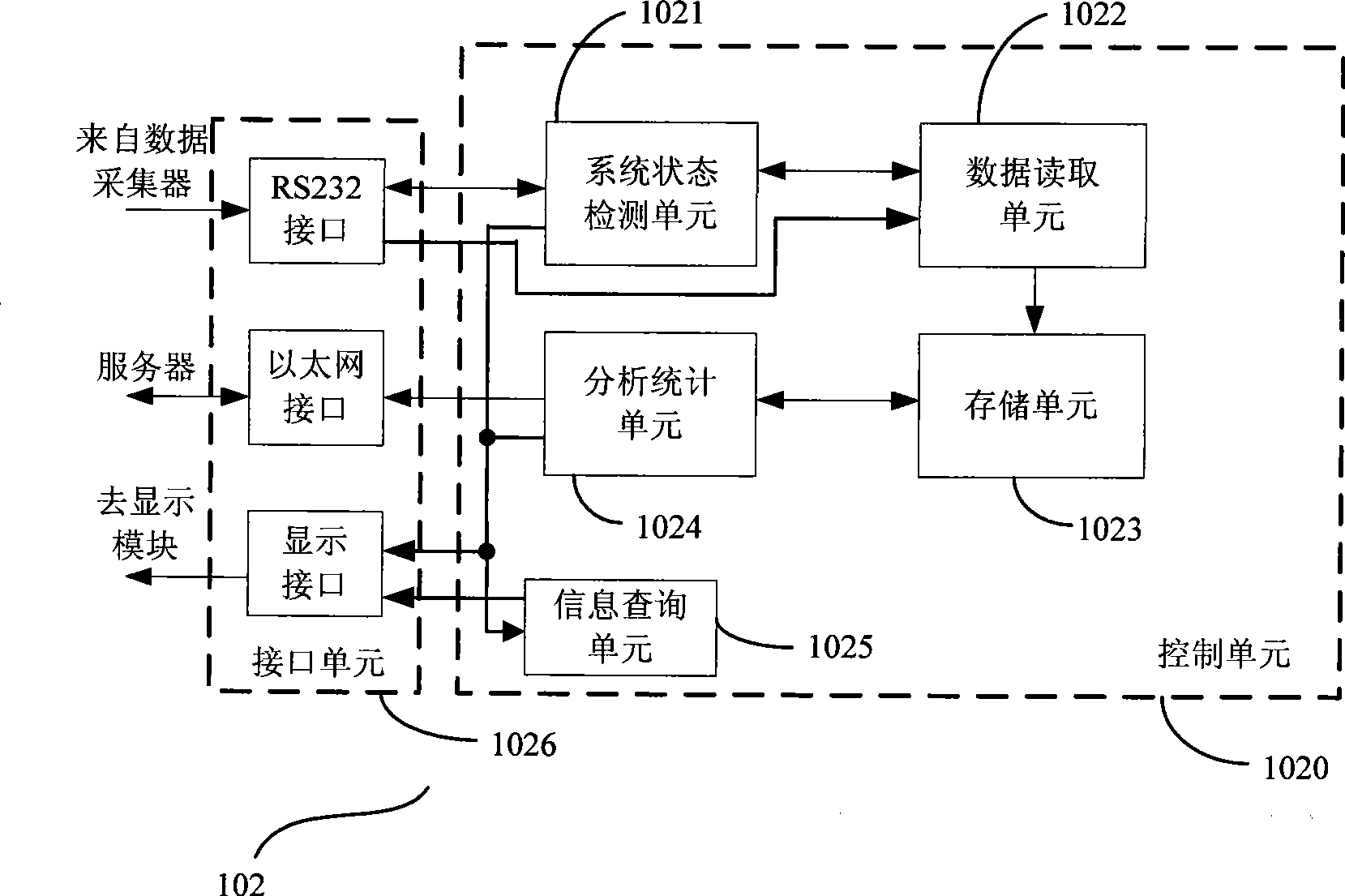

[0042] The system and method for real-time collection and statistical data of the production line of the present invention, after converting all kinds of information produced into digital level, pulse and other signals through one or more data collection terminals, the data collector collects, stores and timely Report to the distributed control machine; the distributed control machine counts and analyzes the production information it reads from multiple data collectors of one or more production lines, and displays some key production data on the display in real time terminal to guide the production line managers to adjust the tempo of production in a timely manner; at the same time, the collected, statistical and analyzed data are regularly reported to the centralized server through the Ethernet interface; Store the production information in the centralized control machine and generate production reports; the production line management personnel can query the various production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com