Method for adjusting and controlling nicotine content in tobacco extract

A tobacco extraction and extraction technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of chemical agent extraction or extract residue, aroma-causing components are easily damaged, and the process is complicated, so as to achieve controllable nicotine content , low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

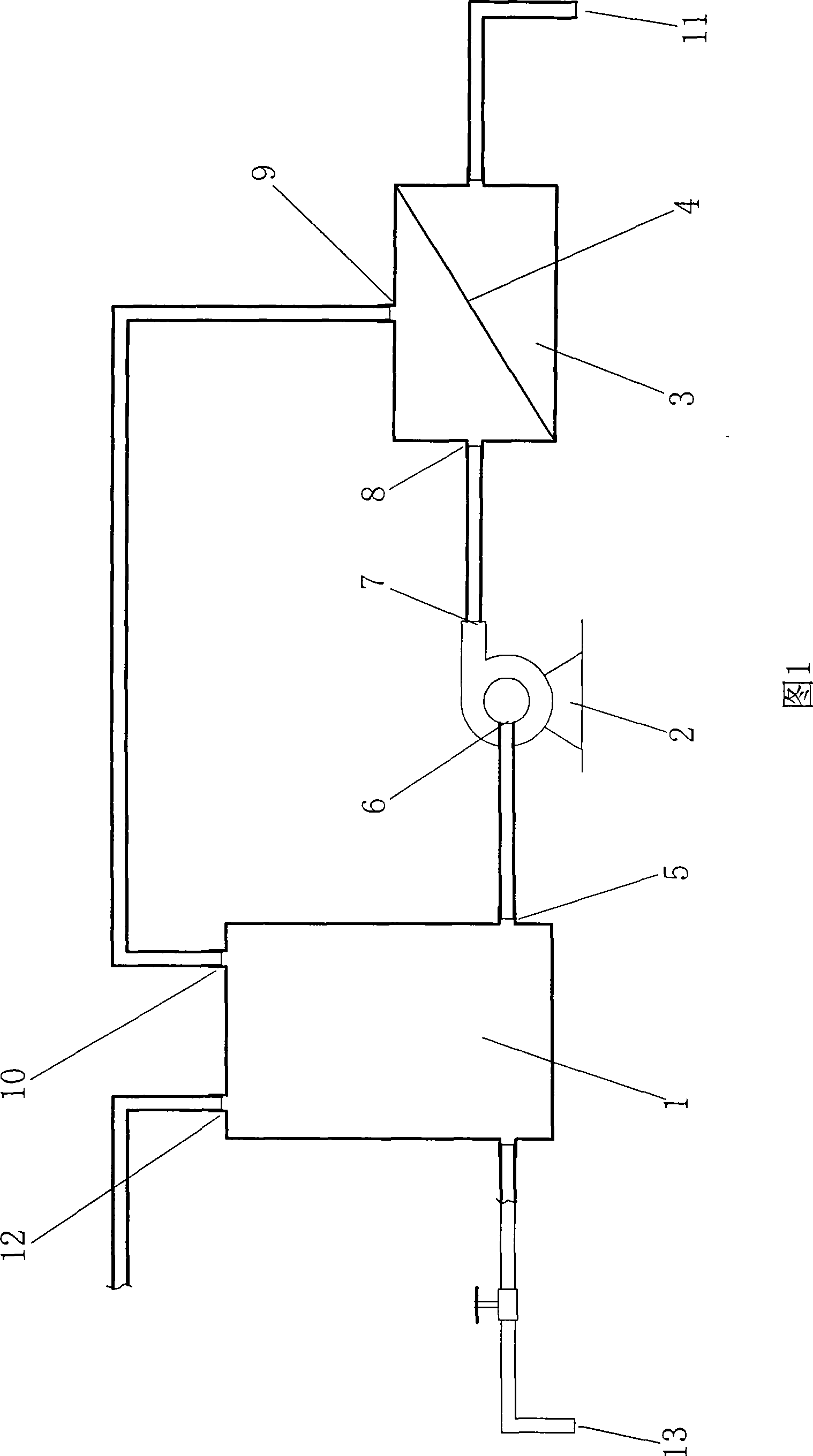

[0017] The method for regulating the nicotine content in tobacco extraction or extract is characterized in that: 20.00 kg of tobacco raw material extraction or extract in the production of reconstituted tobacco leaves by papermaking method is taken, wherein the nicotine content is 1.60%, and the solid content is 65.2%; It is dissolved in 70.00kg of water and stirred evenly, and diluted to a concentration of about 14.5%; the diluted solution is put into an ultrafiltration membrane circulation device for circulating filtration, and the operating temperature is controlled at ≤40°C, and the operating pressure is controlled at ≤23Mpa; Obtain the retentate 43.29kg (concentration is 15.3%) of the low nicotine content that is intercepted by the ultrafiltration membrane and the dialysate 45.8kg (concentration is 13.6%) of the high nicotine content that passes through the ultrafiltration membrane, obtain after the retentate concentration Extract 9.64Kg, wherein the solid content is 68.8%...

Embodiment 2

[0020] The method for regulating the nicotine content in tobacco extraction or extract is characterized in that: 10.00 kg of tobacco raw material extraction or extract in the production of reconstituted tobacco leaves by papermaking method is taken, wherein the nicotine content is 8.73%, and the solid content is 69.6%; It is dissolved in 90.00kg of water and stirred evenly, and diluted to a concentration of about 7.0%; the diluted solution is put into an ultrafiltration membrane circulation device for circulating filtration, the operating temperature is controlled at ≤40°C, and the operating pressure is controlled at ≤25Mpa; Obtain the retentate 32.96kg (concentration is 15.7%) of the low nicotine content that is intercepted by the ultrafiltration membrane and the dialysate 66.54kg (concentration is 2.7%) of the high nicotine content that passes through the ultrafiltration membrane, obtain after the retentate concentration Extract 7.52Kg, wherein the solid content is 69.0%, the...

Embodiment 3

[0023] The method for regulating the nicotine content in tobacco extraction or extract is characterized in that: 10.00kg of tobacco raw material extraction or extract in the production of reconstituted tobacco leaves by papermaking method is taken, wherein the nicotine content is 4.33%, and the solid content is 67.2%; It is dissolved in 40.00kg of water and stirred evenly, diluted to a concentration of about 12.4%; the diluted solution is put into an ultrafiltration membrane circulation device for circulating filtration, the operating temperature is controlled at ≤40°C, and the operating pressure is controlled at ≤25Mpa; Obtain the retentate 17.37kg (concentration is 24.8%) of the low nicotine content that is intercepted by the ultrafiltration membrane and the dialysate 31.47kg (concentration is 5.7%) of the high nicotine content that passes through the ultrafiltration membrane, obtain after the retentate concentration Extract 5.49Kg, wherein the solid content is 79.1%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com