Sorting apparatus of unsanitary reclamation waste

A sorting device and technology for landfilling waste, which is applied in classification, solid separation, filtering and screening, etc., can solve the problems of protective cover depression, large drop, and accumulation in one place, so as to improve the rotating force, drive easily, and reduce waste. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

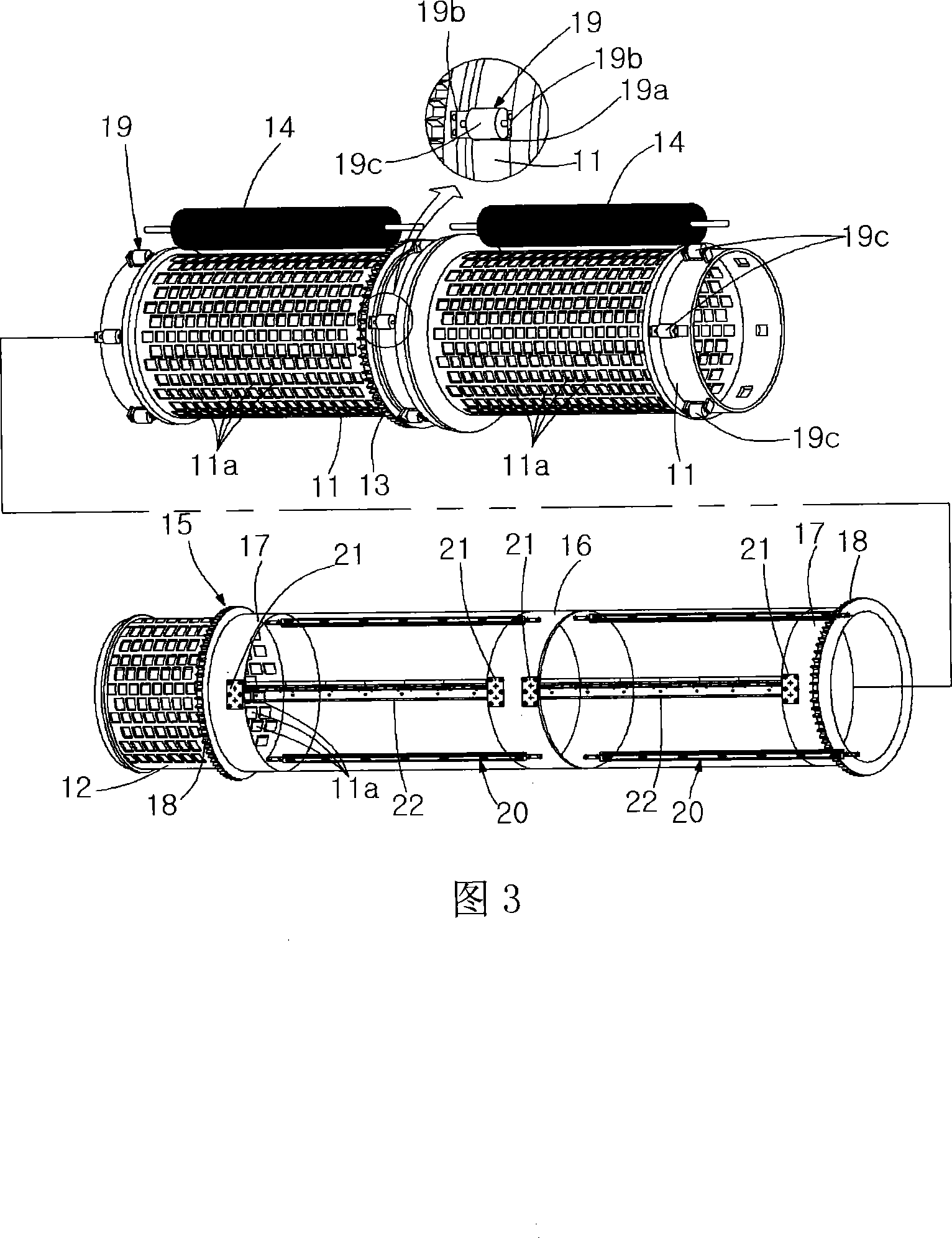

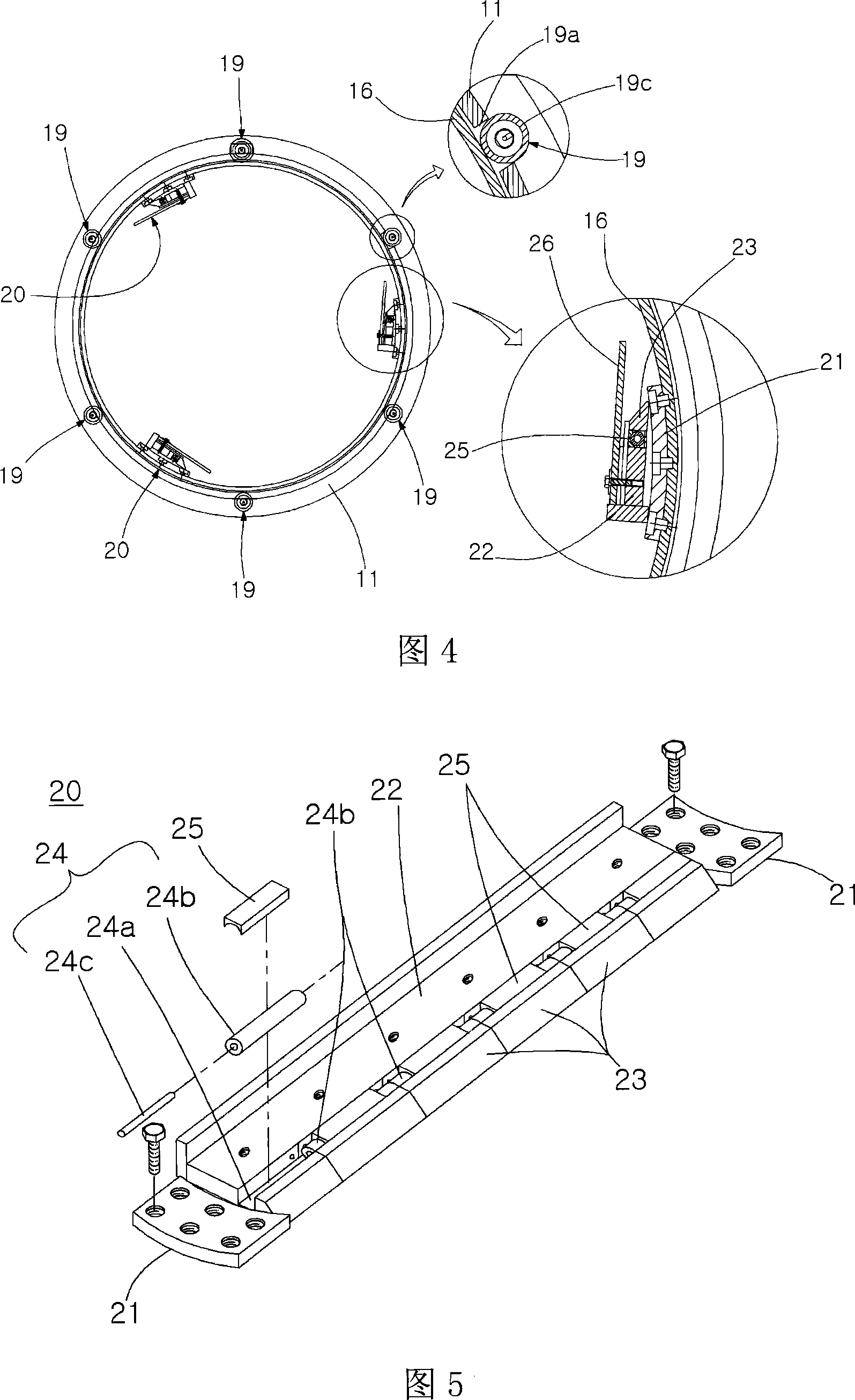

[0059] Hereinafter, the specific content of the embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

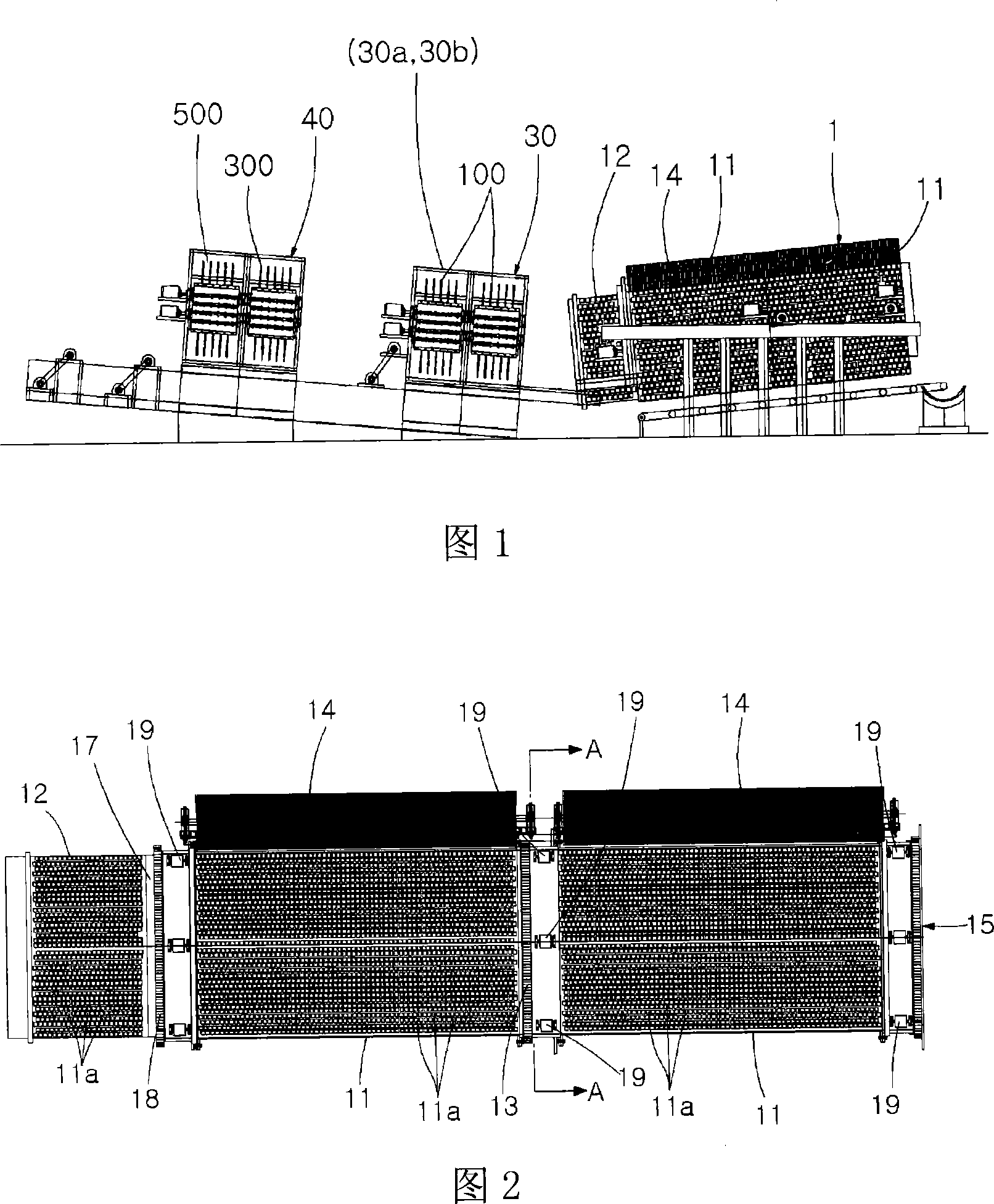

[0060] in the attached picture figure 1 is a schematic diagram showing the structure of the landfill waste sorting device according to the present invention.

[0061] As shown in the figure, the landfill garbage sorting device according to the present invention consists of the following parts: soil and sand separator 1, combustibles separator 30, 40, garbage input device and precision soil and sand separator not shown in the figure.

[0062] For the above-mentioned landfill garbage sorting device, it separates the soil and sand in the garbage mixture (landfill mixed waste) dropped into the soil-sand separator 1 by the garbage feeder, and then sends it to the soil-sand separator 1 The connected soil and sand precision separator (not shown in the figure) is transmitted.

[0063] In this case, the soil-sand sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com