Traction electric motor

A technology for traction motors and electric locomotives, which is applied to transmission devices driven by electric motors, railway car body components, railway braking systems, etc. Eliminate hidden safety hazards, overcome wear and tear, and reduce the amount of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

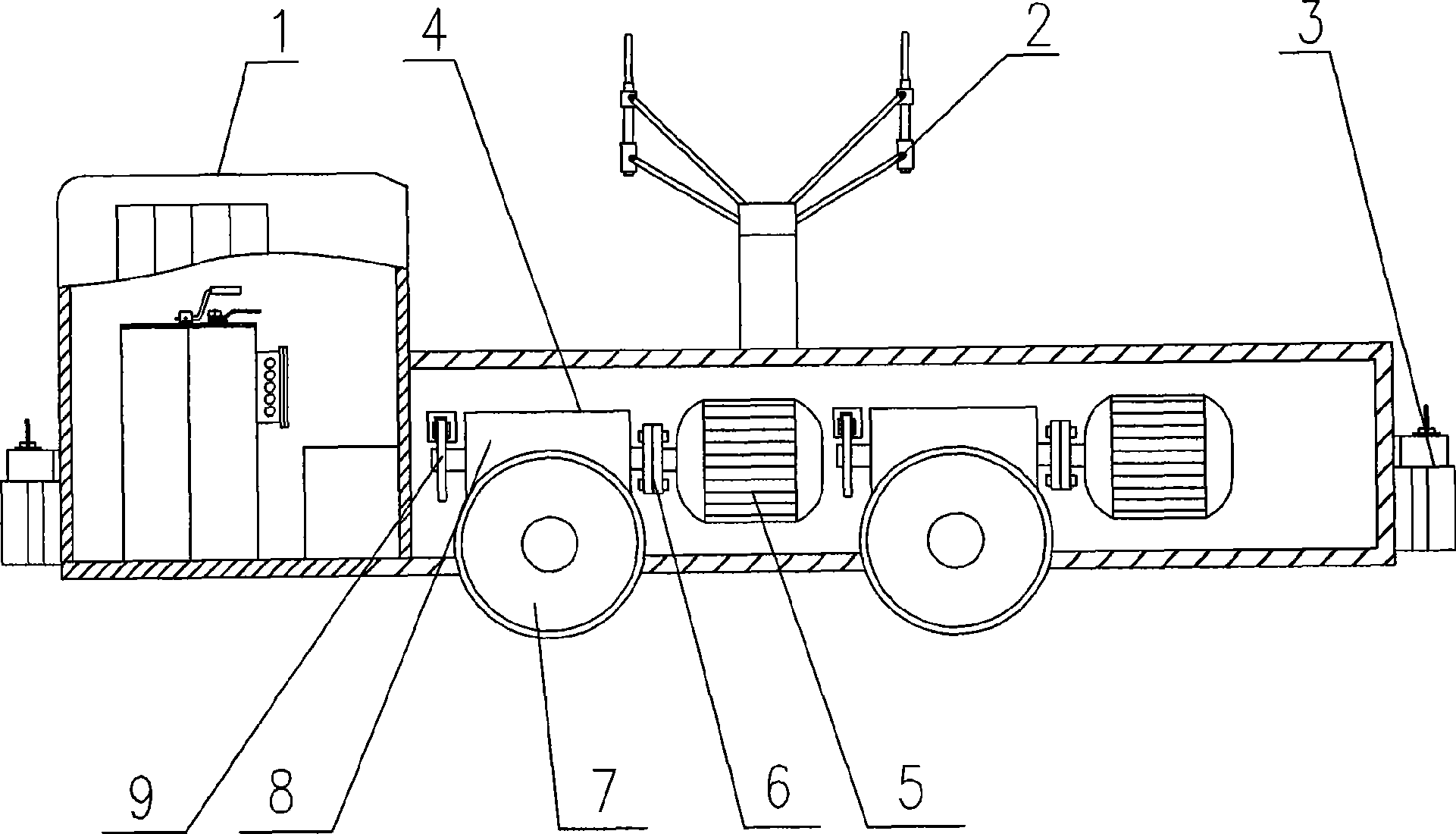

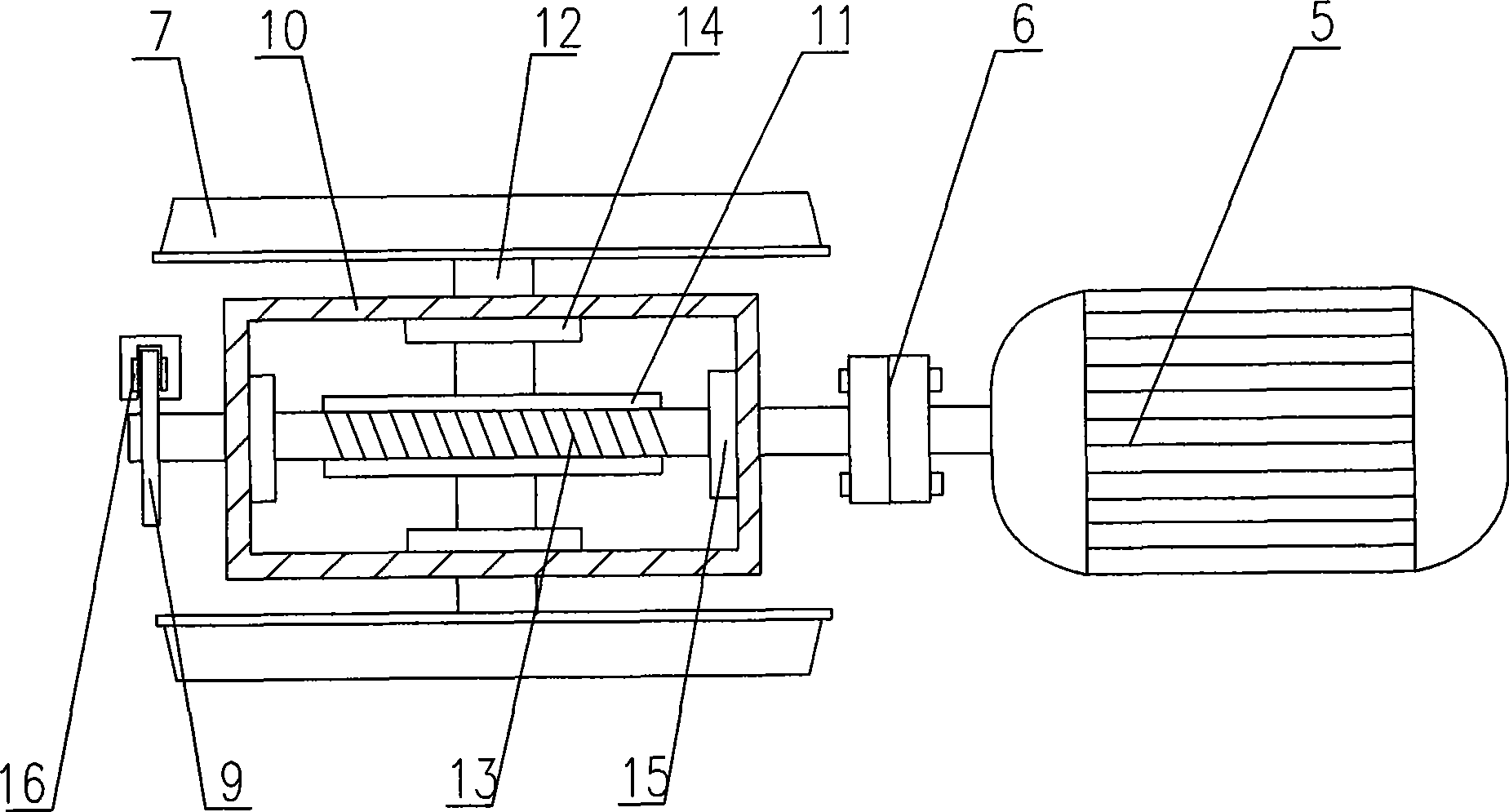

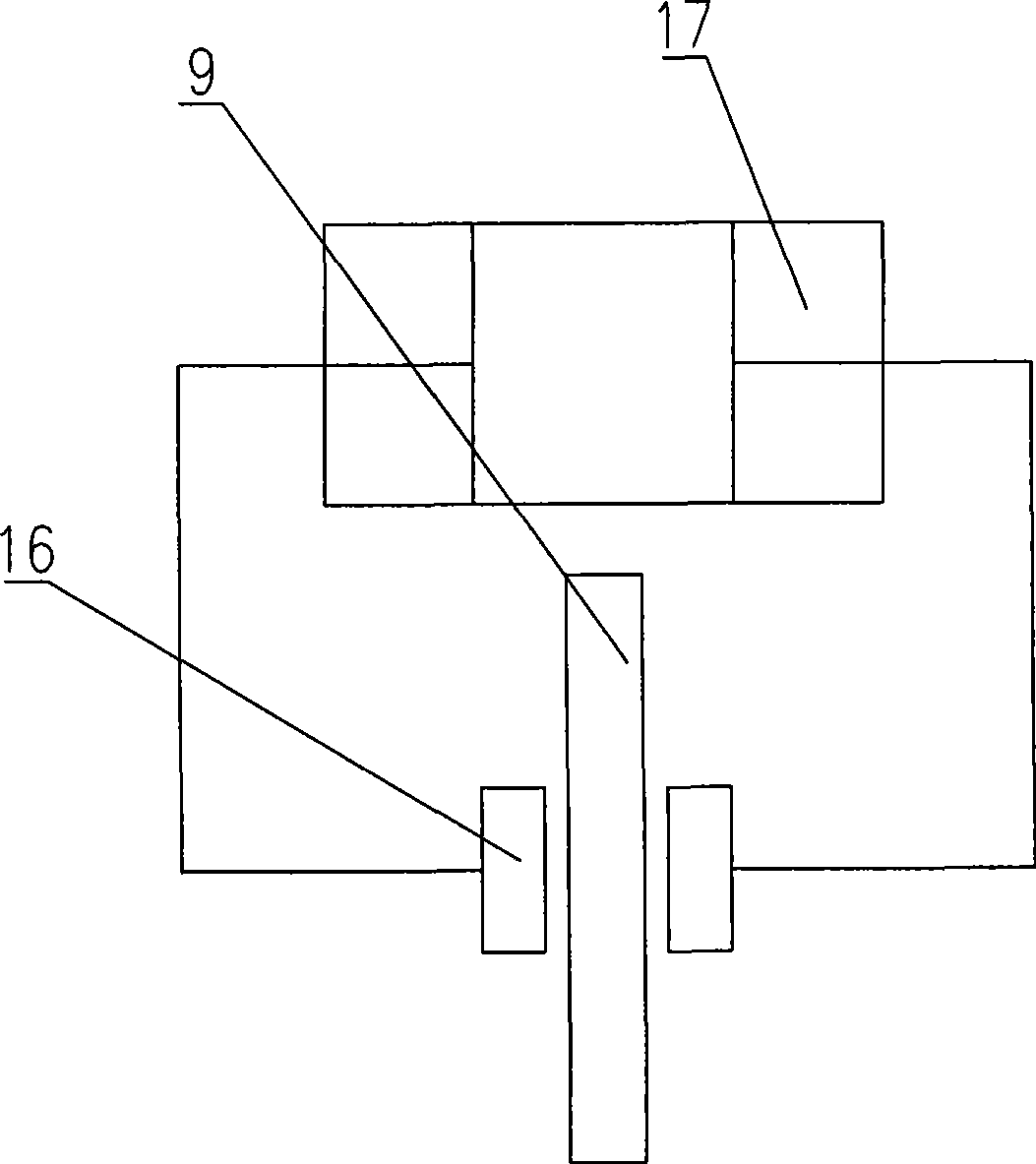

[0012] like figure 1 , figure 2 , image 3 As shown, a traction electric locomotive includes a car body 1, a receiver 2 is arranged on the car body 1, a buffer 3 is installed at the front and rear of the car body 1, and a driving device 4 is arranged in the car body 1, and the driving device 4 Including a traction motor 5, the traction motor 5 is connected with a reduction transmission device 8 through a coupling, and the reduction transmission device 8 is a worm gear transmission reduction device, and a worm wheel 11 and a worm 13 are housed in the reduction box 10, and the worm shaft 12 The two ends extend to the outside of the reduction box 10 and the wheels 7 are mounted on the worm shaft 12; The other end is equipped with a braking device; the worm gear shaft 12 is equipped with a deep groove ball bearing 14; the worm screw 13 is equipped with a tapered roller bearing 15; Moving block 16 and brake disk 9 that are contained on the worm screw 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com