Band steel electrolytic degreasing bath

An electrolytic degreasing, strip steel technology, applied in the electrolytic process, electrolytic components, coatings, etc., can solve the problems of galvanizing troublesome, difficult to wash off, etc., and achieve the effect of ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

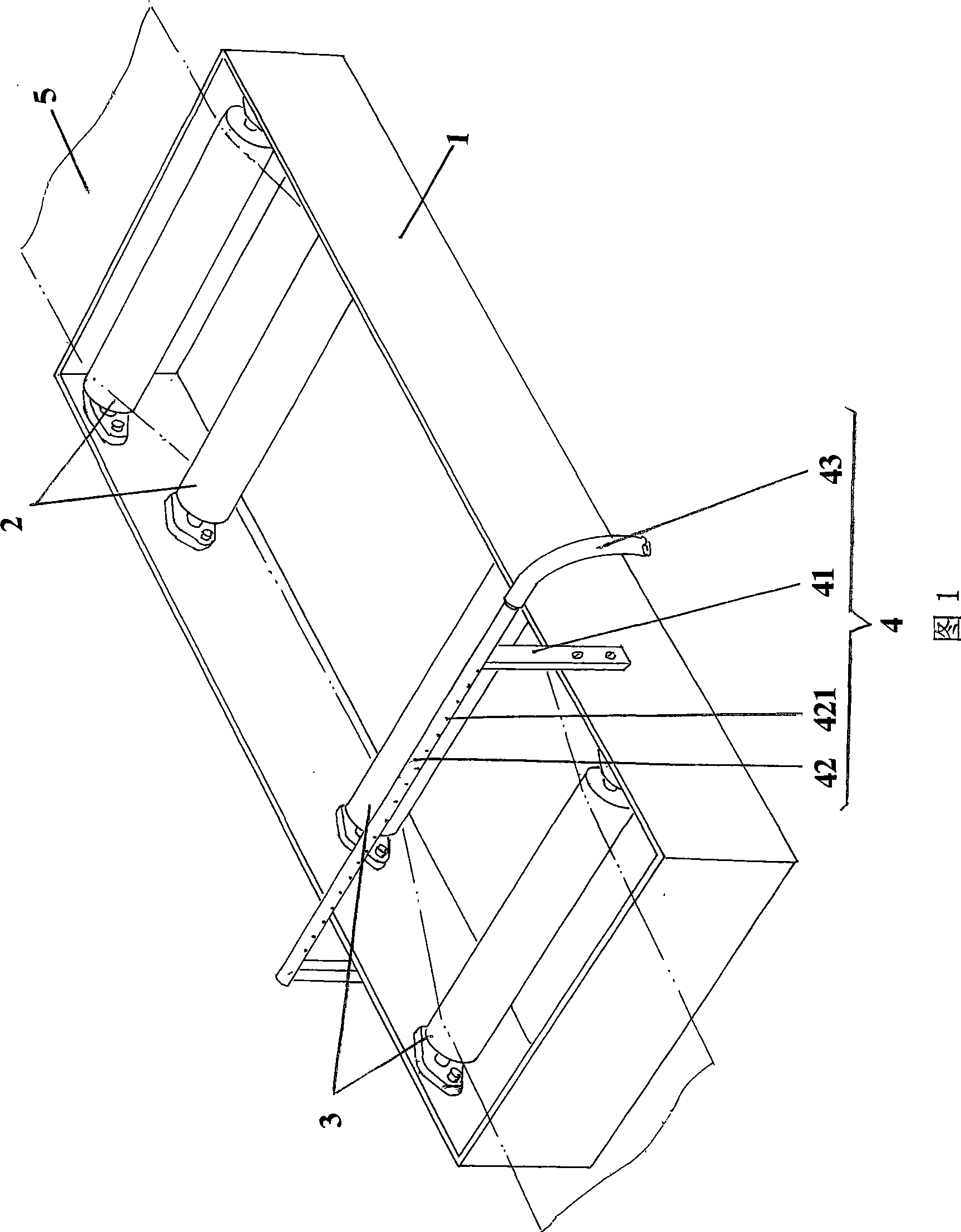

[0016] See also Fig. 1, have provided the known public strip steel degreasing electrolyzer of the industry in the prior art, the tank body 1 of this strip steel electrolytic degreasing tank is the shape of a cuboid, is configured in the chamber of the tank body 1 for removing strip Electrolytic degreasing solution such as lye for the grease on the surface of steel 5. One end of the tank body 1, that is, the right end of the current position shown in Figure 1, is provided with a pair of strip steel introduction rollers 2, specifically: the two ends of the strip steel introduction roller 2 and the corresponding inner wall of the tank body 1 use bearings and add bearings The seat and the tank body 1 are pivoted, and the concept of pivoting mentioned here is a rotatable setting. In this embodiment, although a pair of strip steel lead-in rollers 2 is shown, it can be reasonably increased as required, for example, three or four (ie, two pairs) of strip steel lead-in rollers 2 . A p...

Embodiment 2

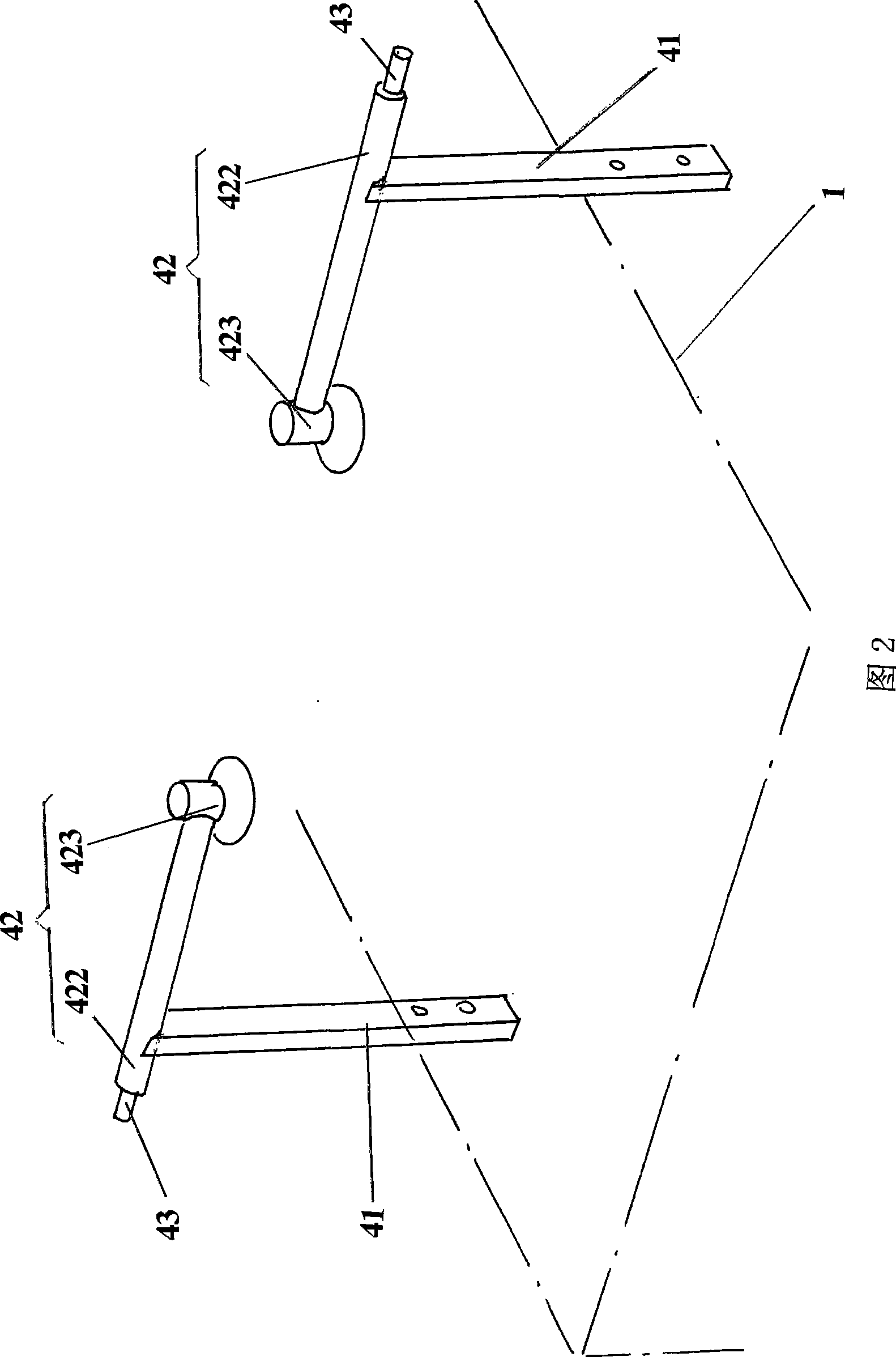

[0020] Please see Fig. 2, another embodiment of shower device 4 is provided, in this embodiment, shower device 4 comprises a pair of brackets 41, a pair of showers 42 and a pair of water pipes 43, a pair of brackets The lower end of 41 is fixed to the corresponding two outer walls of the tank body 1, and a shower 42 is respectively fixed on the upper ends of a pair of brackets 41. Each shower 42 includes a cantilever tube 422 and a spray head 423, and one end of the cantilever tube 422 Fixed with the upper end of the bracket 41, the other end of the cantilever pipe 422 is fixed with the spray head 423, and a pair of water pipes 43 are respectively connected with the corresponding cantilever pipe 422. On the lower strip 5. All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com