Pulsating heat pipe with stable one-way circulation flow

A pulsating heat pipe and one-way circulation technology, applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of difficulty in maintaining one-way circulation flow and complicated operation phenomena, and achieve improved working fluid transportation and heat transfer performance , enhance the effect of stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

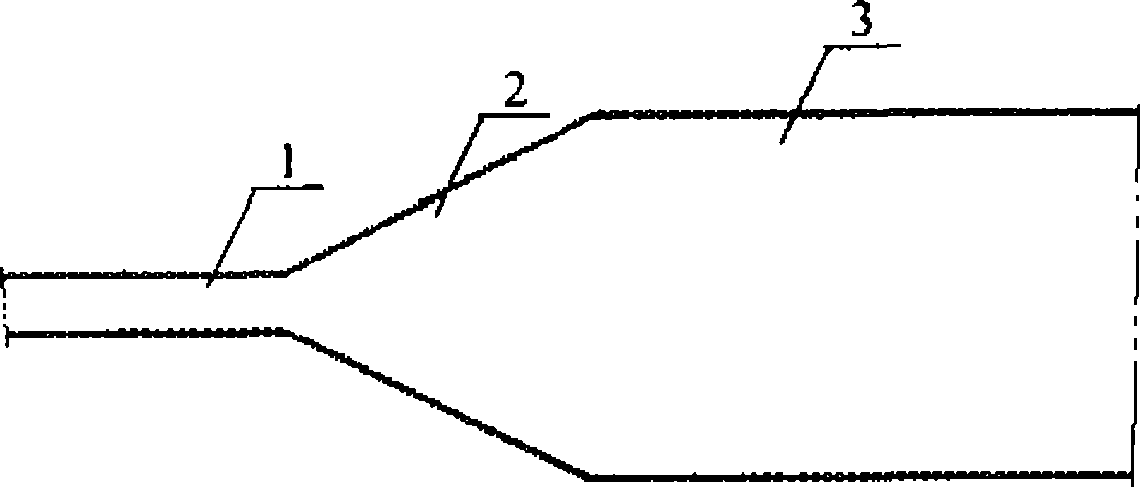

[0019] Such as figure 1 As shown, the pulsating heat pipe is formed by connecting a section of expander tube between two sections of tubes with different inner diameters. That is, a section of expanding pipeline 2 is connected between the thin tube 1 and the thick tube 3 to form a complete flow channel.

Embodiment 2

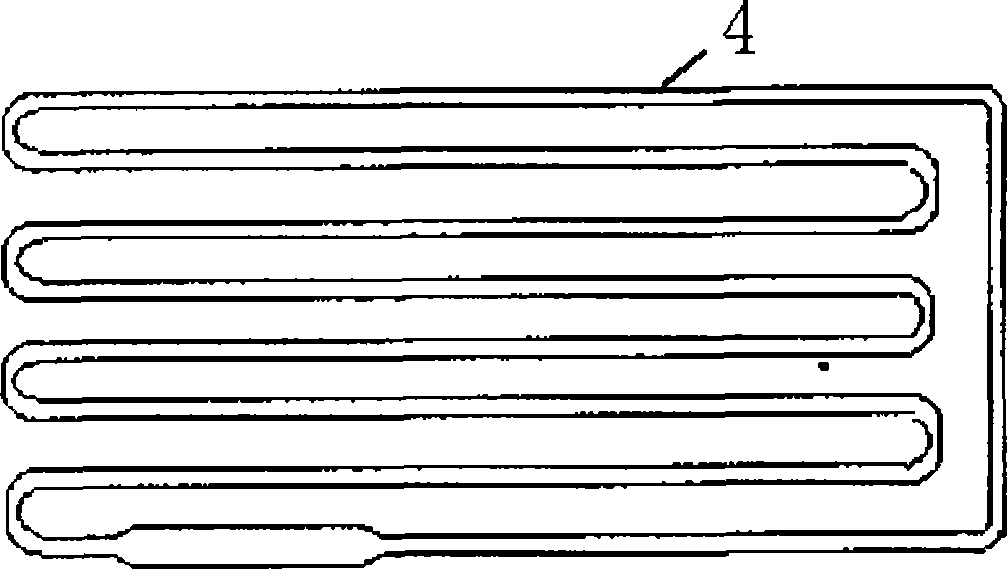

[0021] Such as figure 2 Shown is a modified pulsating heat pipe. The pipe is bent into multiple elbows, the liquid in the pipe is heated and cooled, and a phase change occurs, and heat is transferred through the phase change process and the flow of the working fluid, and the pulsating heat pipe can cool the electronic device. A section of thick pipe with a length of 100mm and an inner diameter of 2mm is installed on the lower left part of the pipeline; the inner diameter of the other parts remains 1.6mm. This structural improvement is equivalent to applying the new structure of the present invention to the rightmost pipeline.

[0022] A piece of thick pipe installed destroys the symmetry and balance of the flow path of the pulsating heat pipe, and its effect is similar to a one-way valve, which makes the flow of the working medium in the pulsating heat pipe dominant in one direction, thus improving the possibility of forming a one-way circulating flow possibility.

[0023]...

Embodiment 3

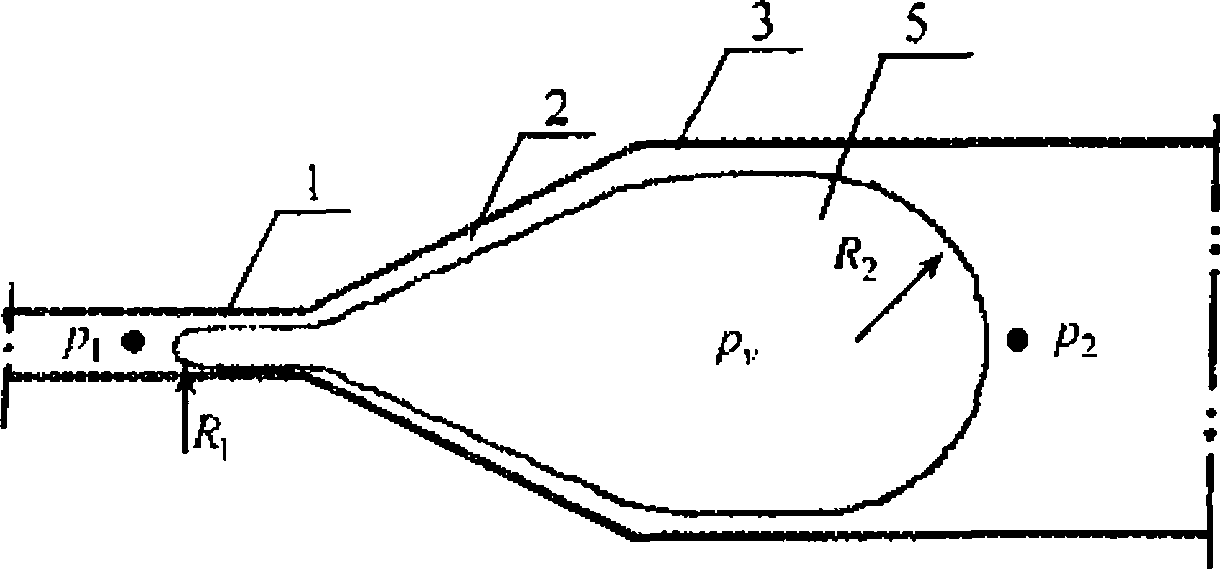

[0025] image 3 is a schematic diagram of the micropump effect. In the expanding pipeline 2, if bubbles 5 are generated periodically, since the shape of the pipeline is gradually expanding, the radius of curvature of the meniscus of the bubbles will change forcibly, and a micropump effect will be produced under the action of surface tension.

[0026] The effect of surface tension creates a pressure difference between the inside of the bubble and the outside liquid,

[0027] p v - p 1 = 2 σ R 1 p v - p 2 = 2 σ R 2

[0028] Therefore there is, p 1 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com