Device for monitoring brewing process based on wireless sensor network technique

A wireless sensor and process monitoring technology, applied in the direction of instruments, signal transmission systems, etc., can solve the problems of limited operating range of cables, harsh working environment, affecting working environment, etc., to improve stability and production capacity, realize digitalization and information. The effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

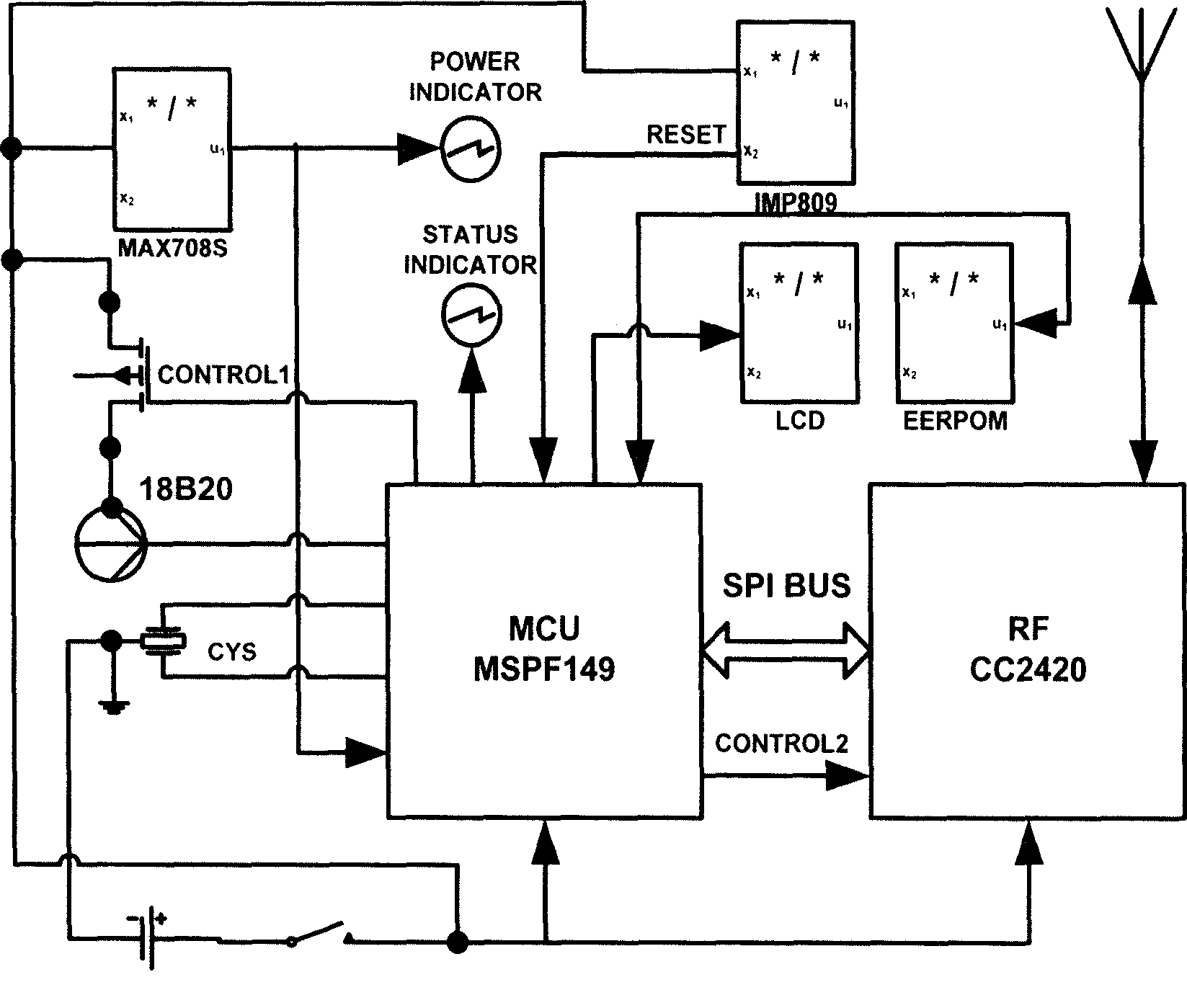

[0033] The schematic diagram of the typical brewing process monitoring equipment based on wireless sensor network provided by the present invention is as follows: figure 1 shown. In an example of wine-making process monitoring, the monitoring node is required to have the following functions:

[0034] 1. The on-site temperature can be collected regularly;

[0035] 2. Each node can have three measurement sensors, which can collect temperature values at three different locations;

[0036] 3. With working status indication and under-power indication;

[0037] 4. With automatic wake-up function, it can communicate wirelessly with the base station and other nodes at regular intervals;

[0038] 5. It can regularly transmit data to the base station through the wireless network, and accept and execute the instructions of the base station.

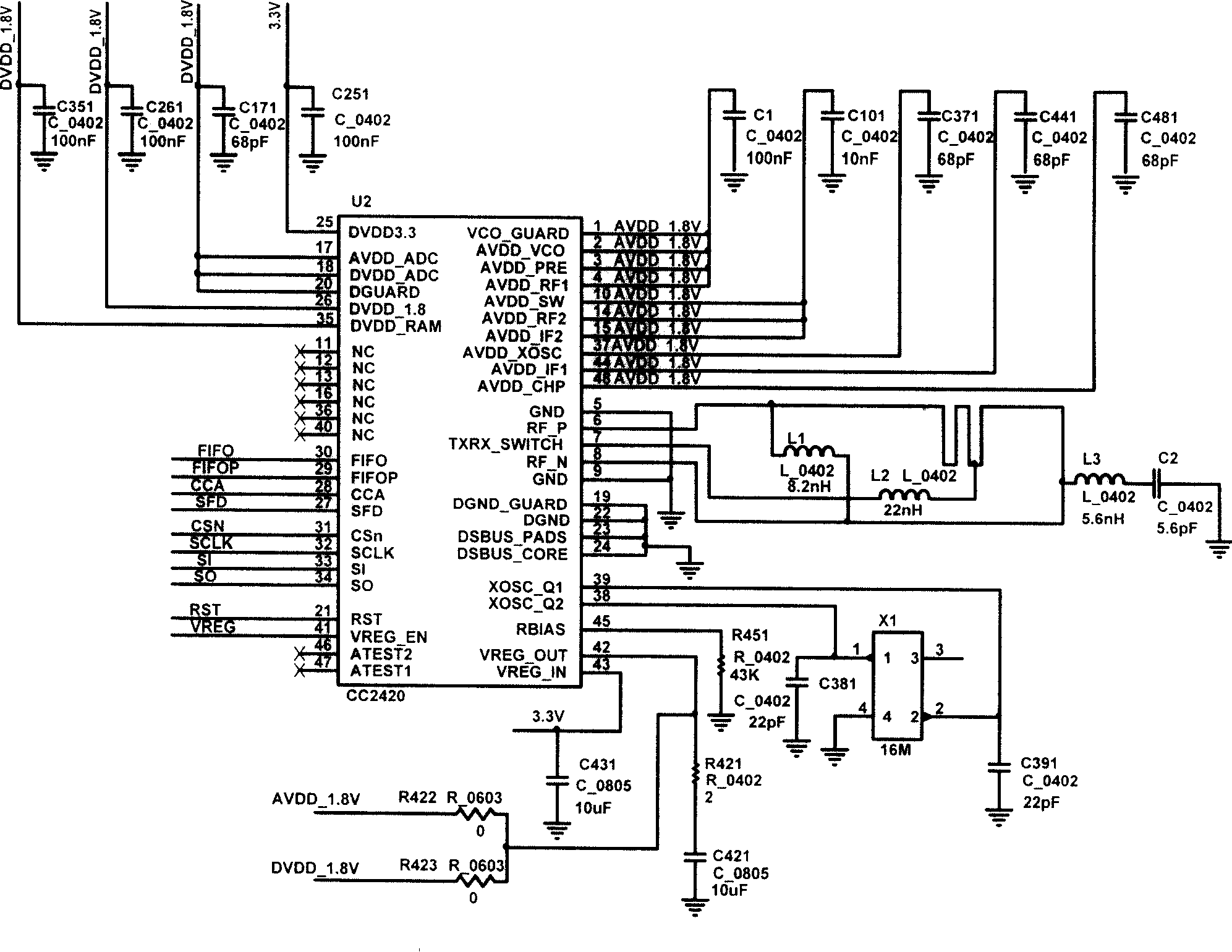

[0039] Such as figure 2 as shown, figure 2 The system uses MSP430 as the schematic diagram of the processor.

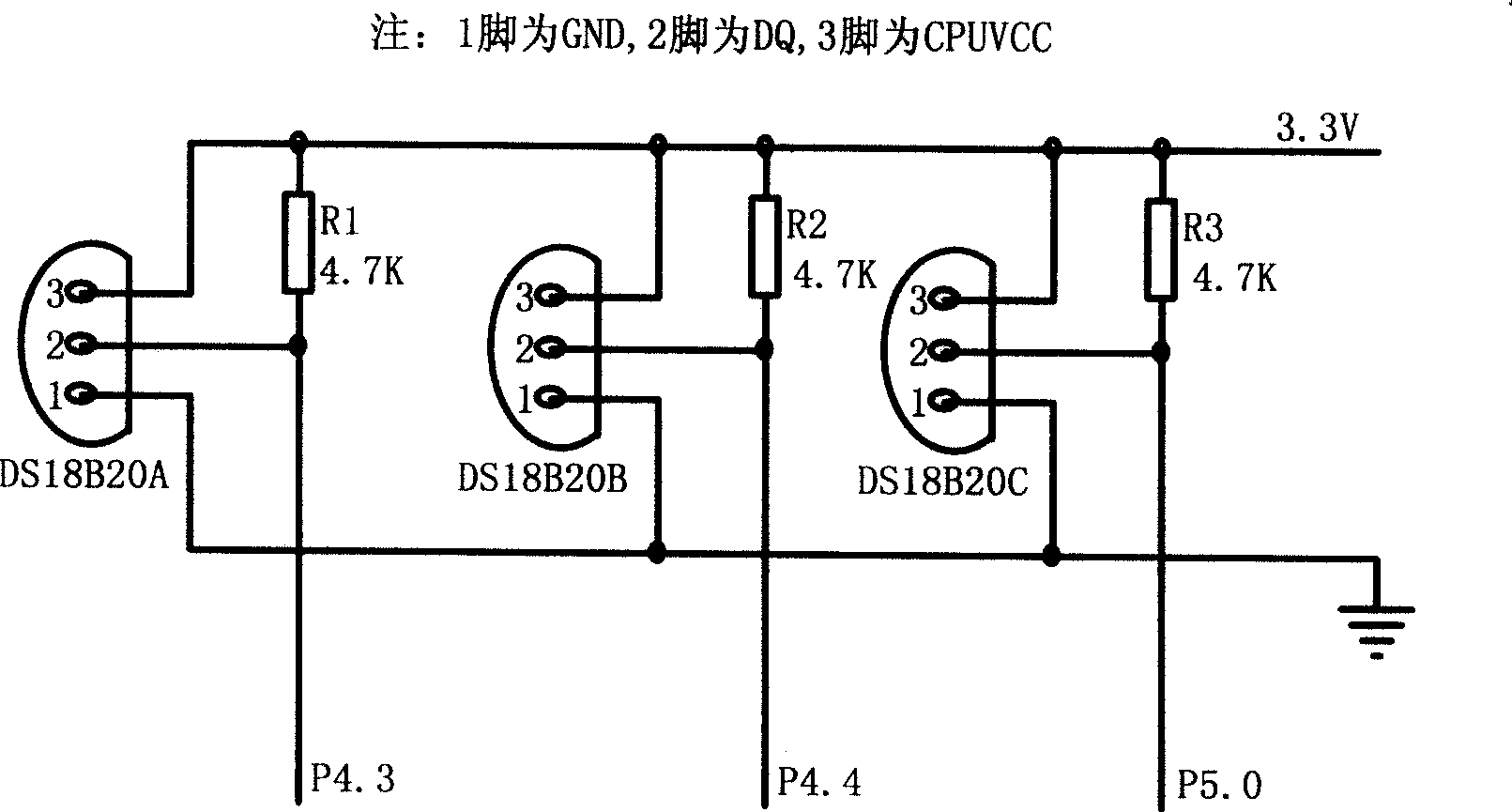

[0040] Such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com