Multiple polar combined magnetic core

A magnetic core and multi-pole technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, electrical components, etc., to achieve the effect of optimizing magnetic circuit distribution, reducing volume and expanding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

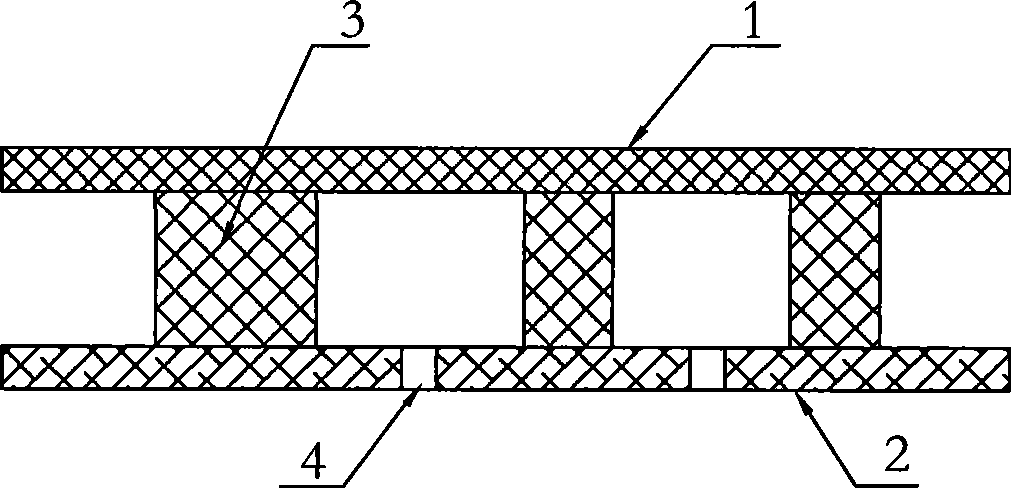

[0022] Embodiment 1: The multi-pole combined magnetic core, such as figure 1 As shown in the figure, it consists of a top plate 1, a bottom plate 2, and five magnetic core columns 3. Two threading holes 4 are arranged on the bottom plate 2. The magnetic core column 3 is an integral structure, and the magnetic core column 3 is fixed on the bottom plate 2. superior.

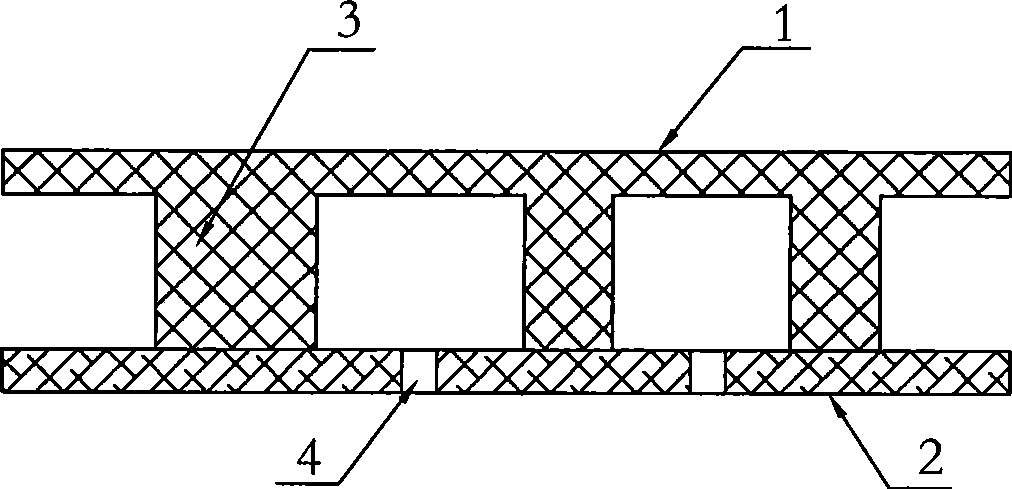

[0023] As a special case of Embodiment 1, the magnetic core column 3 is integrated with the top plate 1, such as figure 2 shown,

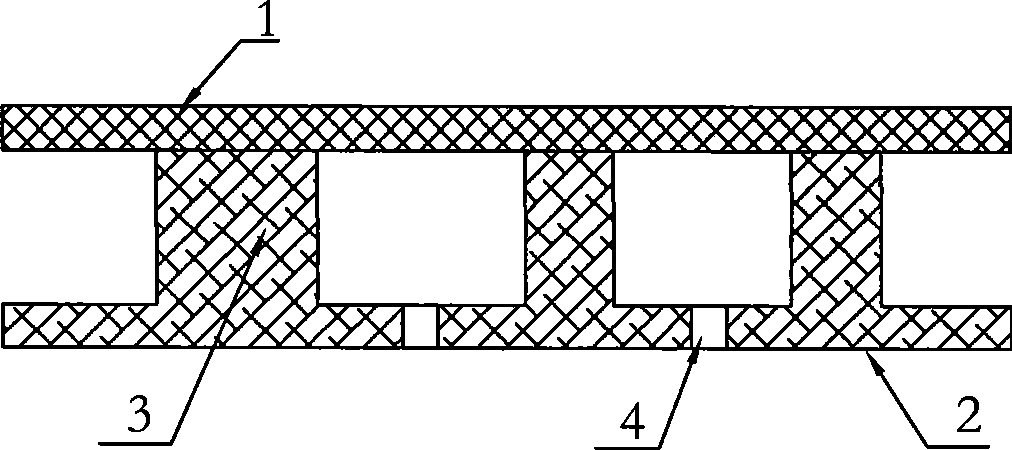

[0024] Or the core column 3 is integrated with the base plate 2, such as image 3 shown.

Embodiment 2

[0025] Embodiment 2: The multi-pole combined magnetic core, such as Figure 4 As shown in the figure, it consists of a top plate 1, a bottom plate 2, and five magnetic core columns 3. There are two threading holes 4 on the bottom plate. The magnetic core column 3 is a split structure, and the upper magnetic core column 31 is fixed on the top plate. 1. The upper and lower magnetic core columns 32 are fixed on the base plate 2.

[0026] As a special example of the second embodiment, the upper magnetic core leg 31 is integrated with the top plate 1 , and the lower magnetic core leg 32 is integrated with the bottom plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com