Winding form for winding a saddle coil

A technology of coil winding and winding body, which is applied in the direction of winding, electric components, superconductor elements, etc., and can solve problems such as cracking and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

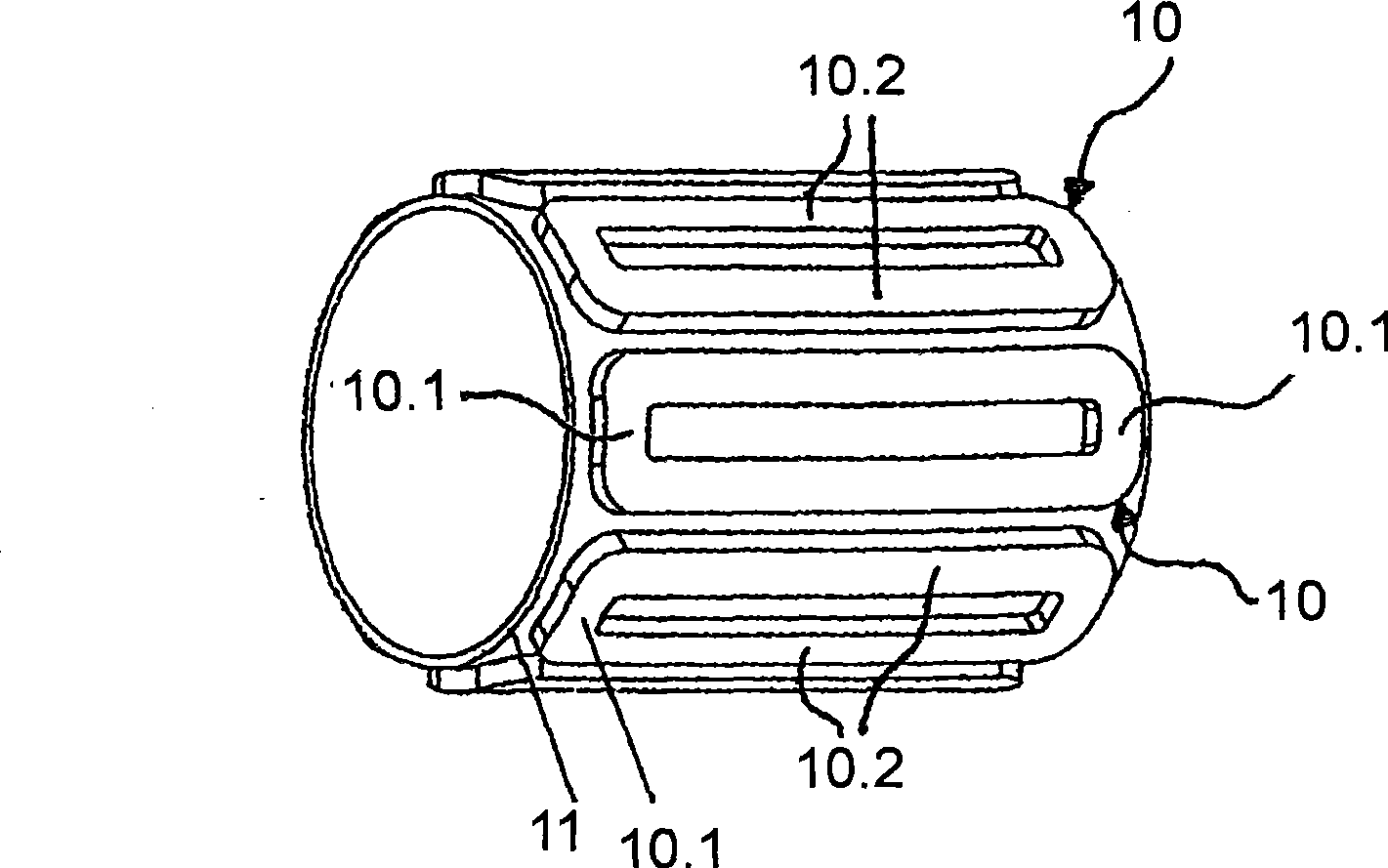

[0030] figure 1 The armature in includes a hollow cylinder 11 on which eight saddle coils 10 are arranged at equal intervals. Each saddle coil 10 has two coil ends 10.1 and two longitudinal sides 10.2. The connection of the saddle coil 10 , the cooling structure of the coil and the support structure of the armature as well as other details concerning the armature have been omitted for the sake of clarity.

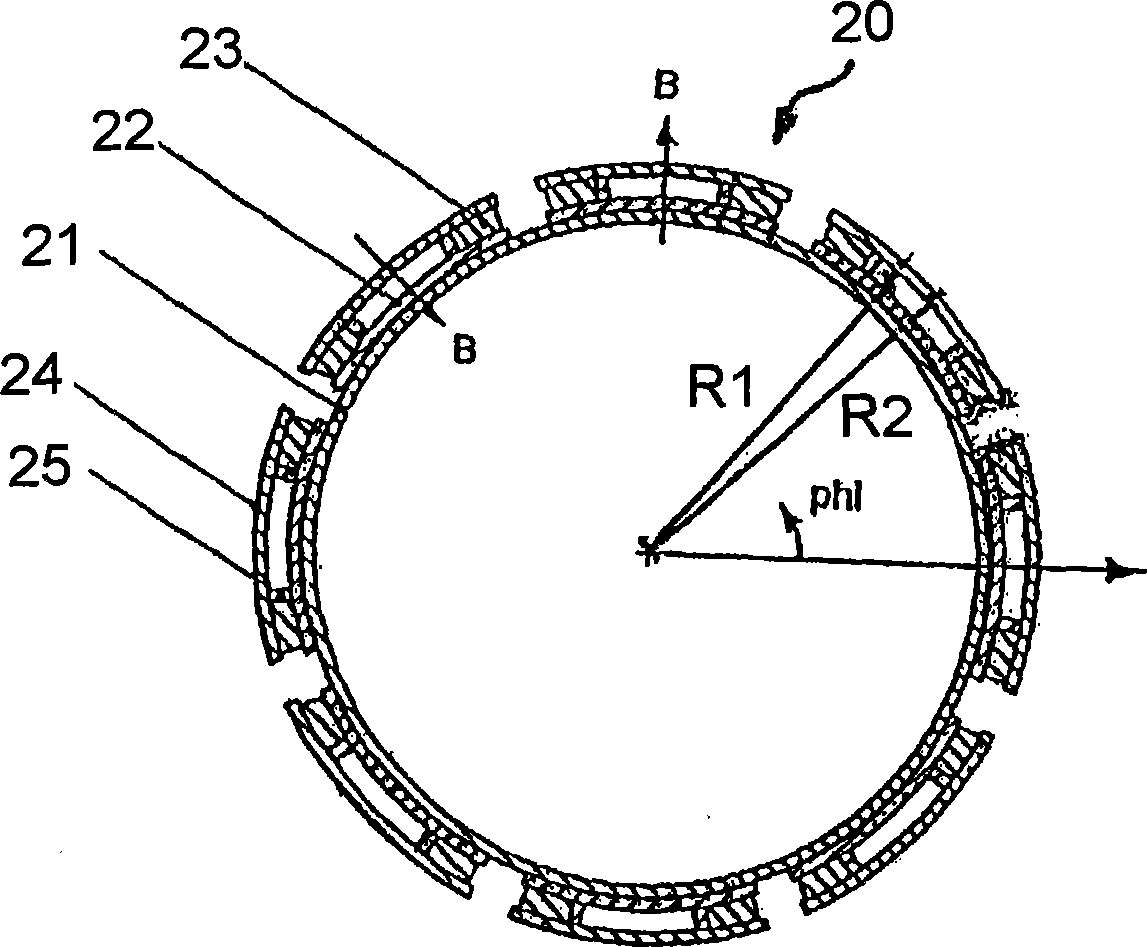

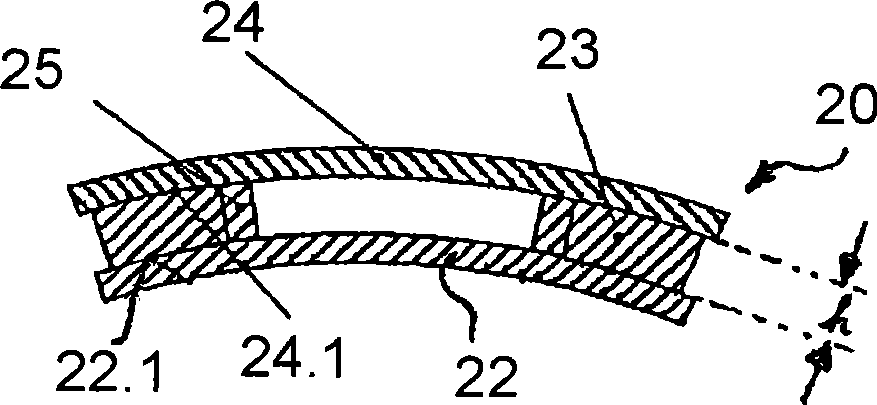

[0031] figure 2 A cross-sectional view of an armature shown in FIG. 1 but comprising a saddle coil 20 according to the invention is shown. This section is perpendicular to the axis of rotation and lies in the region of the longitudinal sides of the saddle coil 20 . Eight saddle-shaped coils 20 are installed on the hollow cylinder 1, and these saddle-shaped coils 20 are image 3 Shown enlarged. The saddle coils 20 each comprise a saddle coil winding body and a saddle coil winding 23 made of strip-shaped thin-layer HTSL, which is also called an HTSL winding or simply a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com