Microphone manufacturing method

A manufacturing method and microphone technology, applied to electret electrostatic transducers, sensors, electrostatic transducer microphones, etc., can solve the problems of increasing the resistance of diaphragm vibration and affecting the sensitivity of microphones, and achieve good air tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

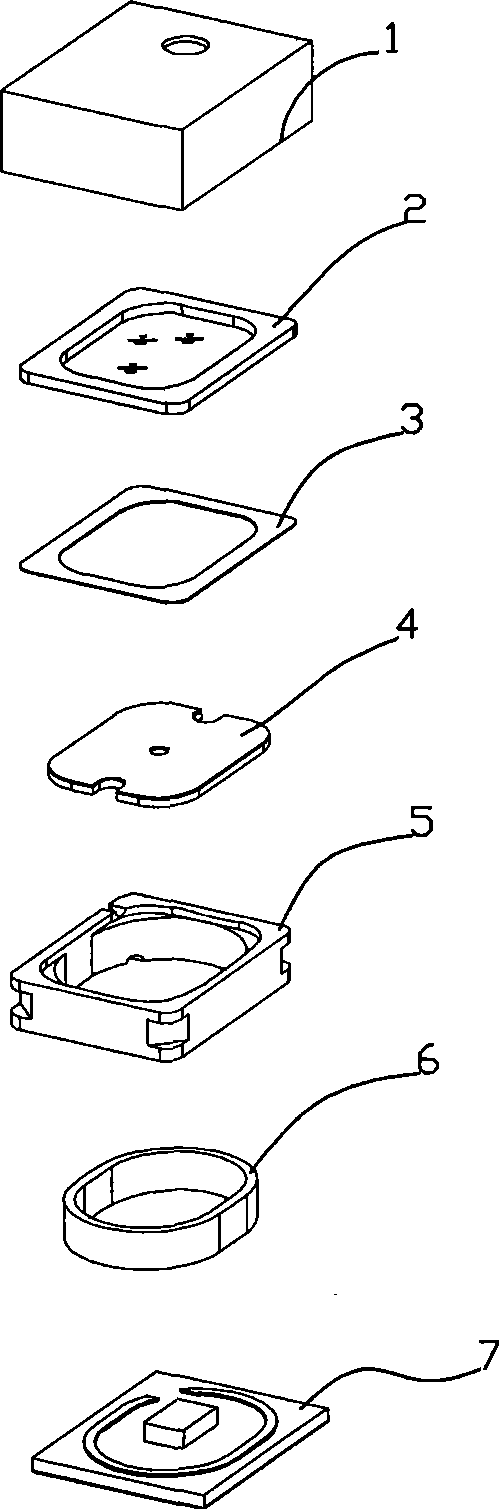

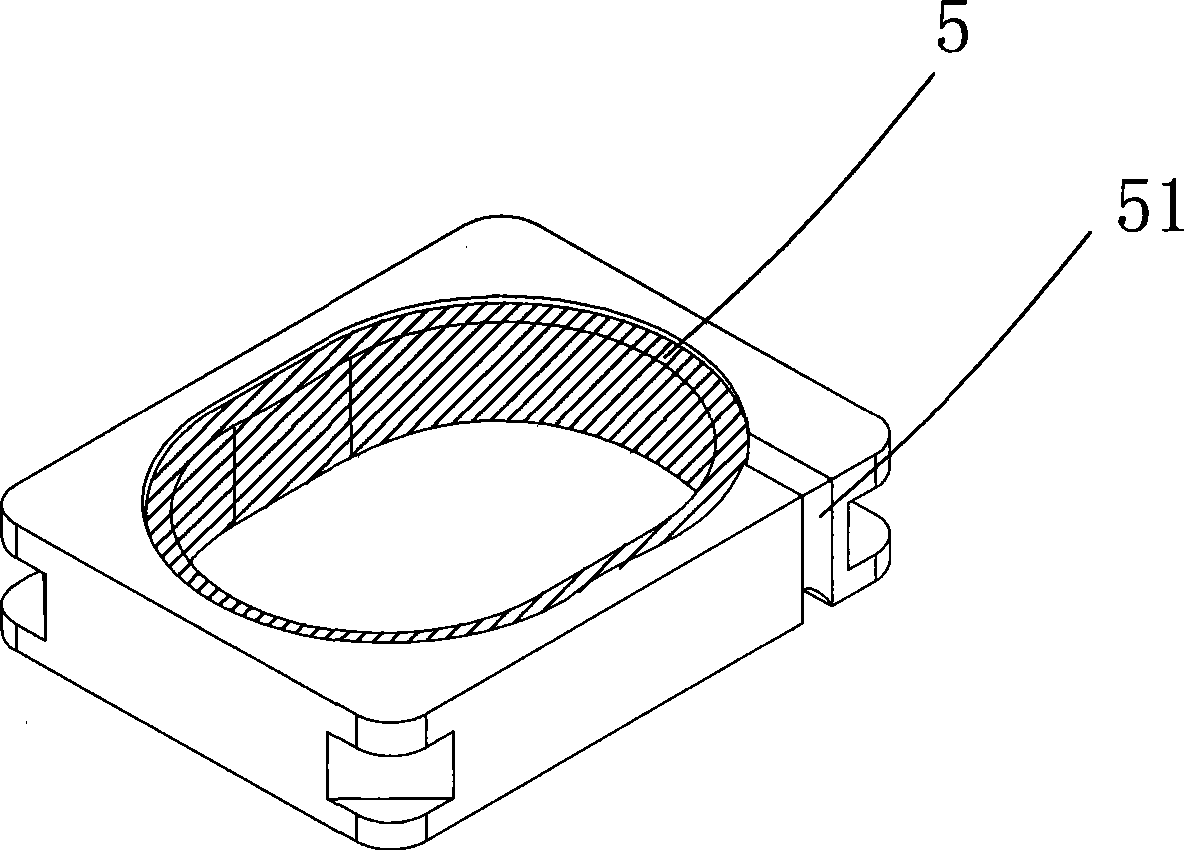

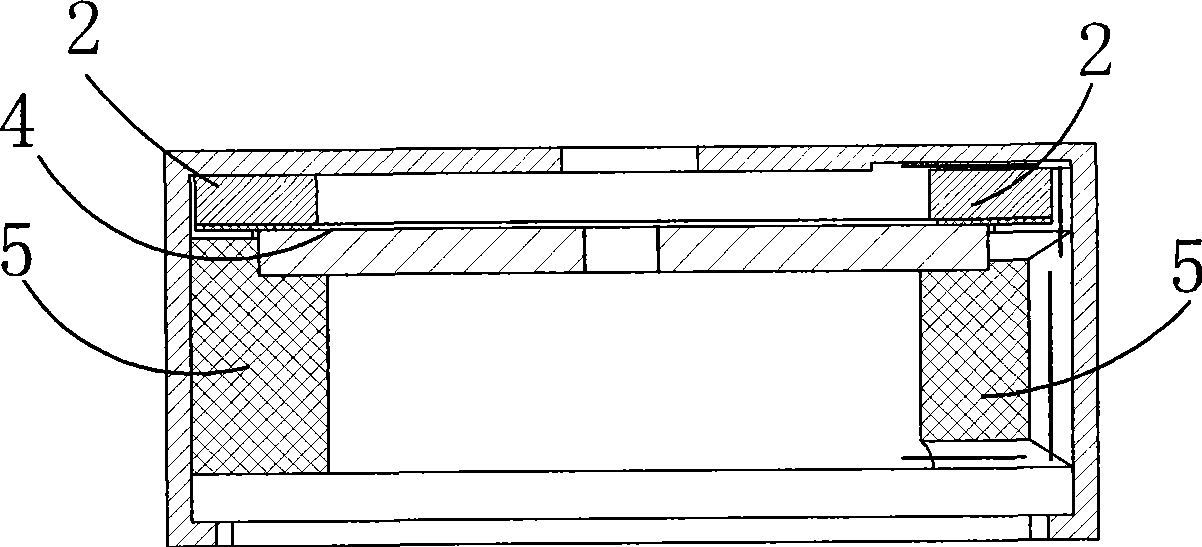

[0021] Such as figure 1 As shown, in an embodiment provided by the present invention, the microphone includes a housing 1, a diaphragm group 2 housed in the housing 1, a gasket 3 placed on the diaphragm group 2, and a back pole seat adjacent to the gasket 3 5. The back plate 4 embedded in the back plate 5 , the connection ring 6 connected with the back plate 4 , and the circuit board 7 electrically connected with the casing 1 . Wherein, the back pole plate 4 and the connecting ring 6 are accommodated in the back pole seat 5 respectively.

[0022] The housing 1 may take various shapes (eg cup-shaped, rectangular, D-shaped or trapezoidal-shaped). The housing 1 can be made of alternating layers of conductive and non-conductive material, or a conductive coating can be applied on the inside of the non-conductive layers, enabling the diaphragm pack 2 to be electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com