Thermophoretic fractionalization of small particles

A technology of particles and conductive particles, which is applied in the field of solid conductive nanoparticles or semiconductive nanoparticles, and can solve the problem that the conductivity of nanotubes does not reach that of nanotubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

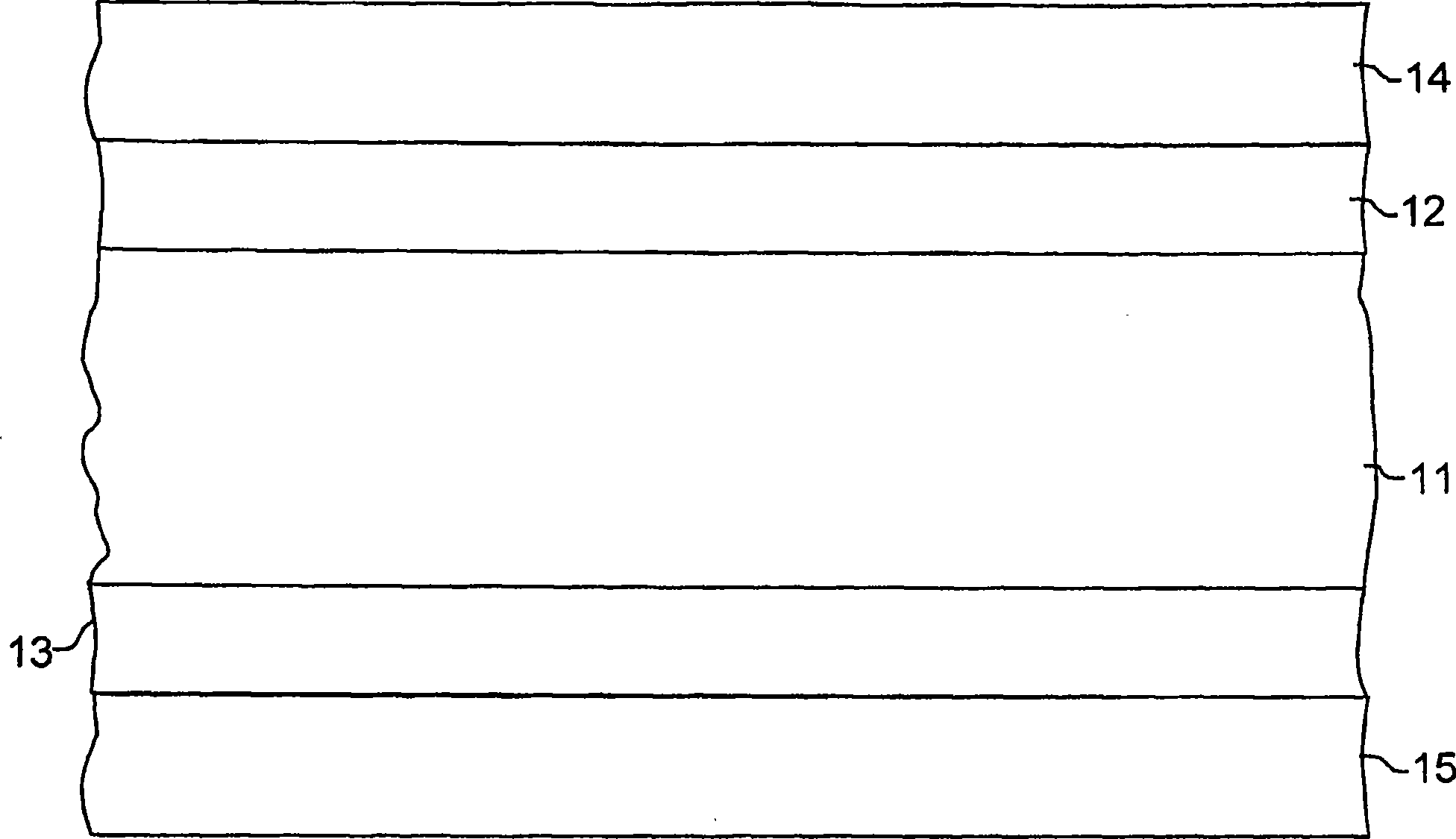

[0011] For comparison with the method of the present invention, refer to figure 1 , showing the conventional thermophoresis method. exist figure 1 In , solution 11 is shown, which includes a carrier liquid and particles. These particles are typically polymers, glass such as silica, or one of a wider variety of particles or mixtures of particles processed by known thermophoretic methods. The solution is contained between the walls of the vessel; a cold wall 12 cooled by cooling means indicated at 13 , and a warm wall 13 cooled by cooling means indicated at element 15 . When a temperature gradient develops in the liquid adjacent to the cold wall 12, particles from the liquid carrier 11 can deposit on the surface of the cold wall. this is in figure 2 is shown in , where particles 17 are attached to the surface of element 12 .

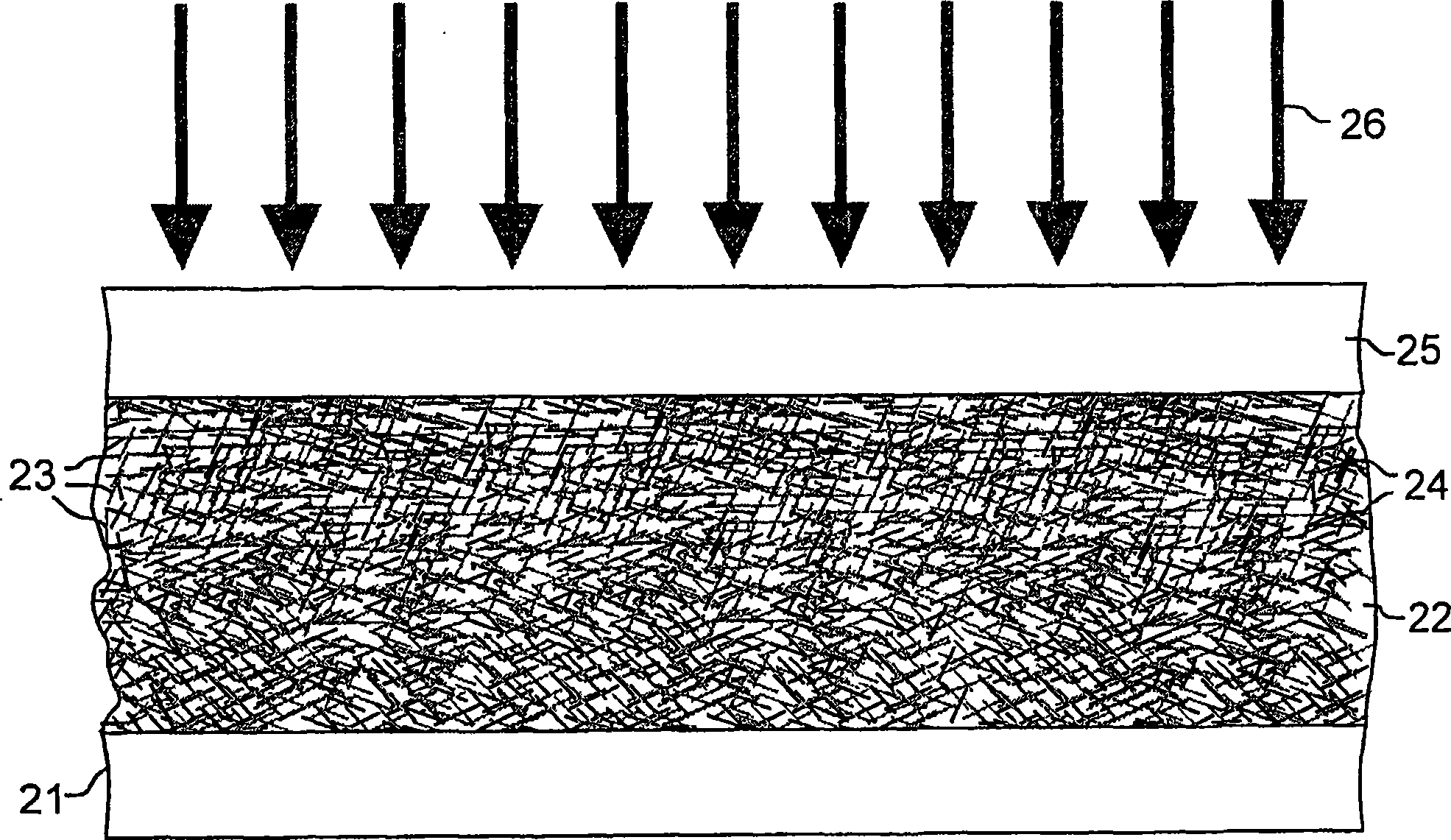

[0012] A variant of thermophoretic processing is applied to the separation method of the present invention. It was found that efficient gradients f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com