Negative-angle press-working die

一种金属模具、负角的技术,应用在成型工具、金属加工设备、制造工具等方向,能够解决弯曲程度深、难负角成形、加工对象截面形状复杂等问题,达到削减成本、降低制作成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

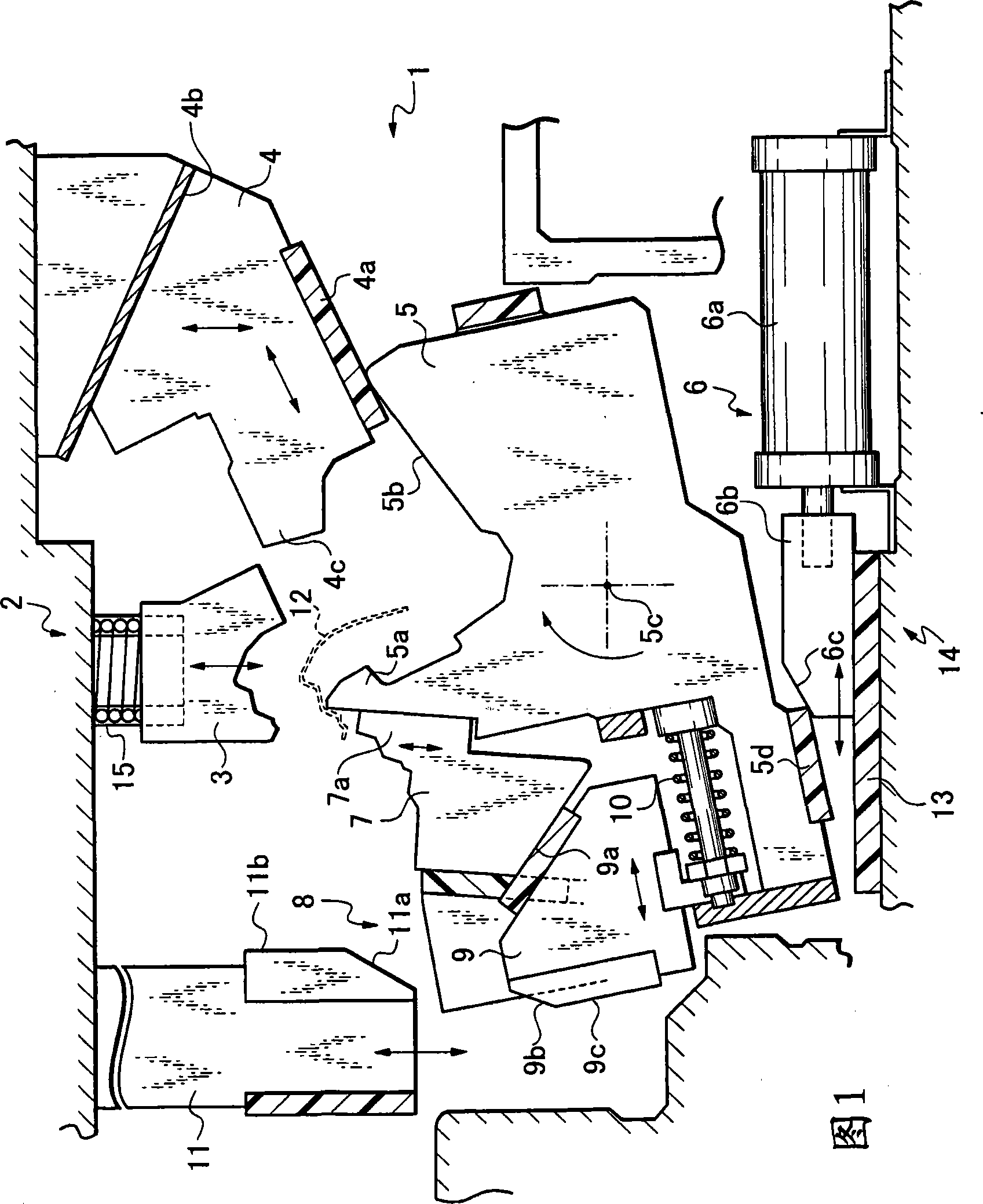

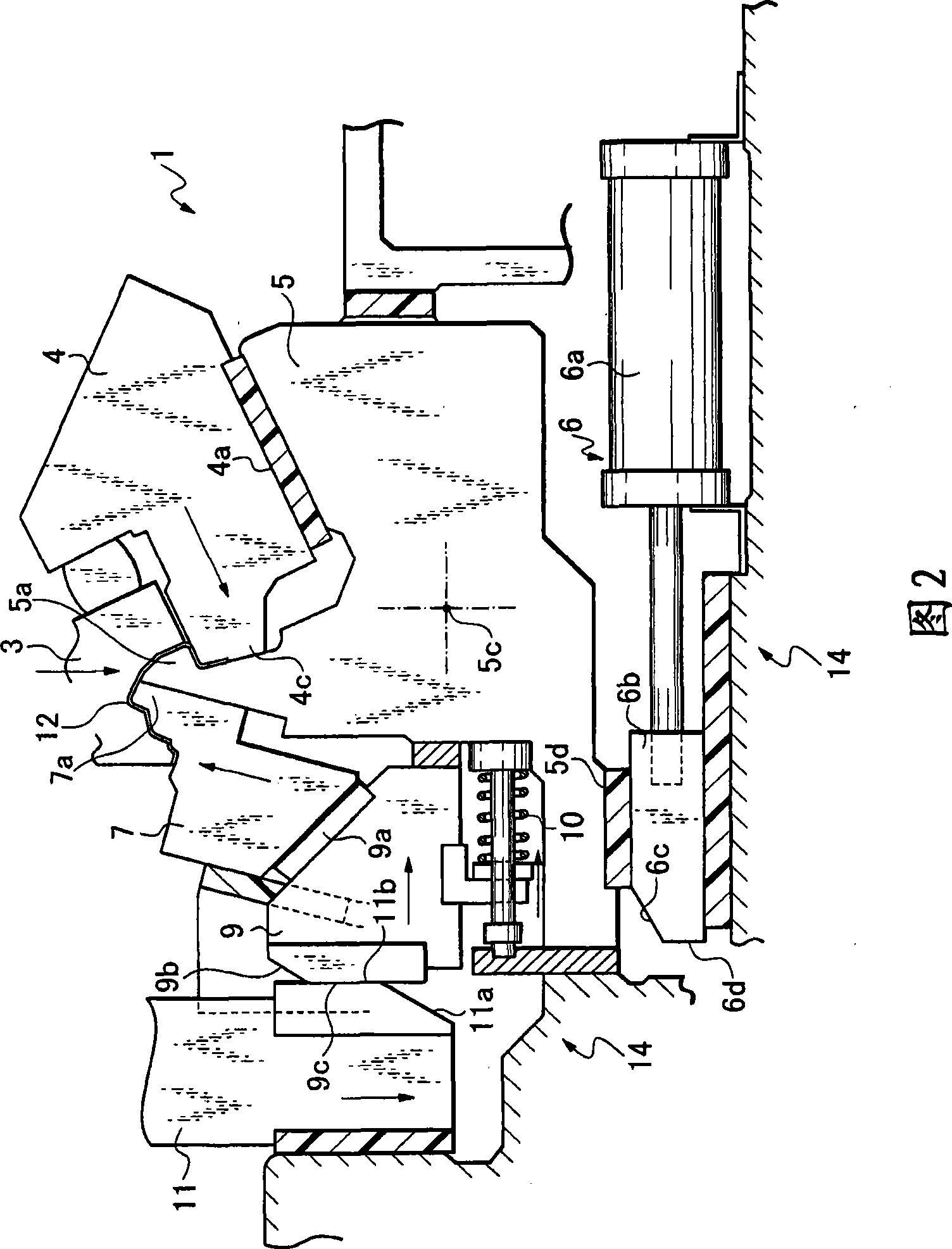

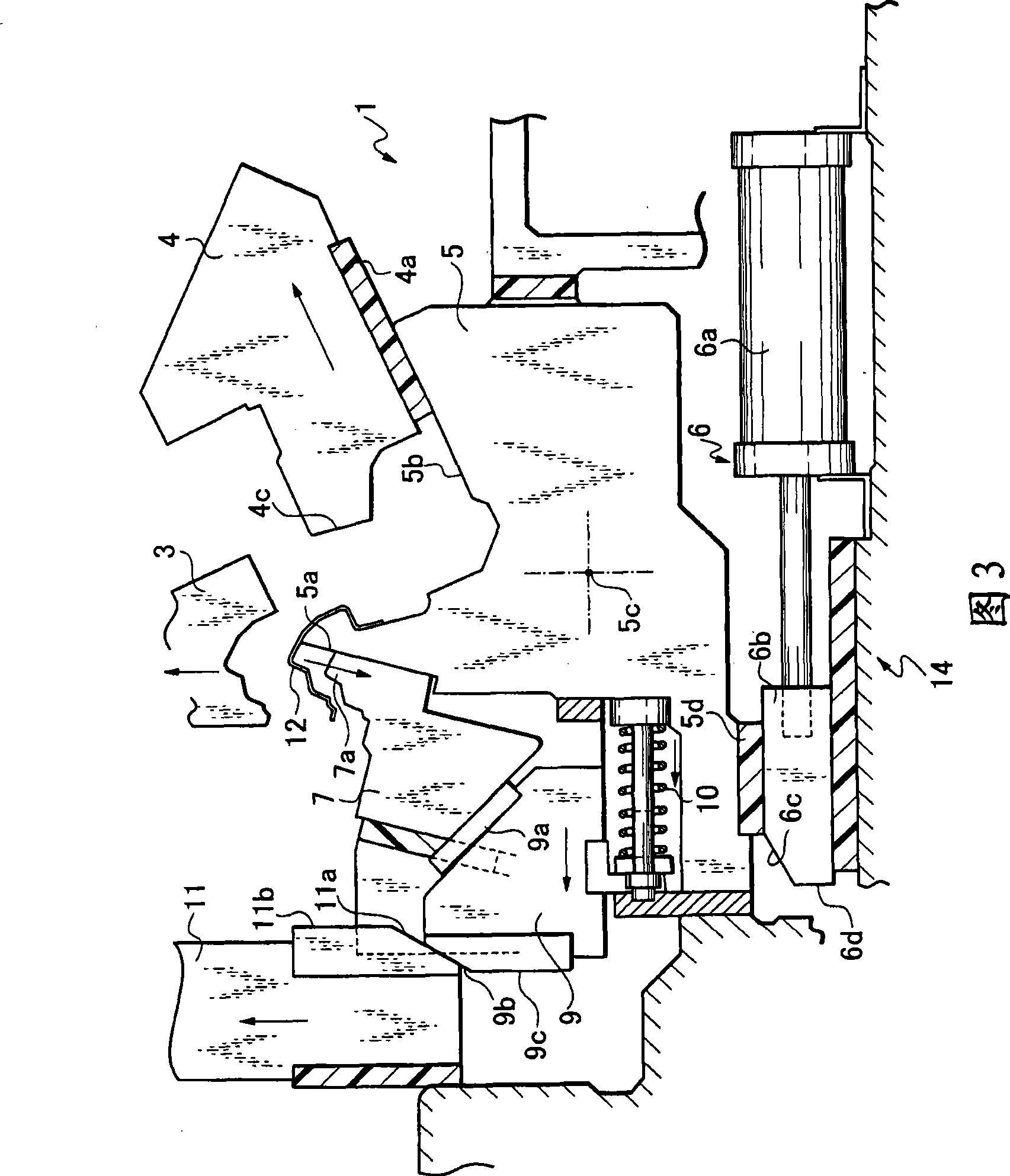

[0019] Fig. 1 is a diagram showing a schematic structure of a stamping die 1 for forming a negative angle according to an embodiment of the present invention. The pad 3 on the upper die 2 that can be lifted up and down freely, the hanging cam 4 that acts as a sliding cam and can slide freely in the lateral direction, the rotary cam 5 that rotates around the center of rotation 5c, and is used to make the rotary A driving mechanism 6 for rotating the cam 5 , a slidable slider 7 having a workpiece holding portion 7 a , and a slide driving mechanism 8 for sliding the slider 7 . The above-mentioned hanging cam 4 functioning as a sliding cam is not limited to a hanging cam, and may be a cam freely slidably supported on the lower die.

[0020] The suspension cam 4 is suspended from the upper die 2 via a cam surface 4b, and a cam surface 4a is provided on the lower side, and a curved blade 4c is formed at the front end. The hanging cam 4 is supported on the upper die 2 so as to slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com