Pretensioned prestressing steel pipe concrete pipe pile and producing method thereof

A technology of steel pipe concrete and production methods, which can be applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as weak bearing capacity, unsatisfactory driving resistance, and small bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

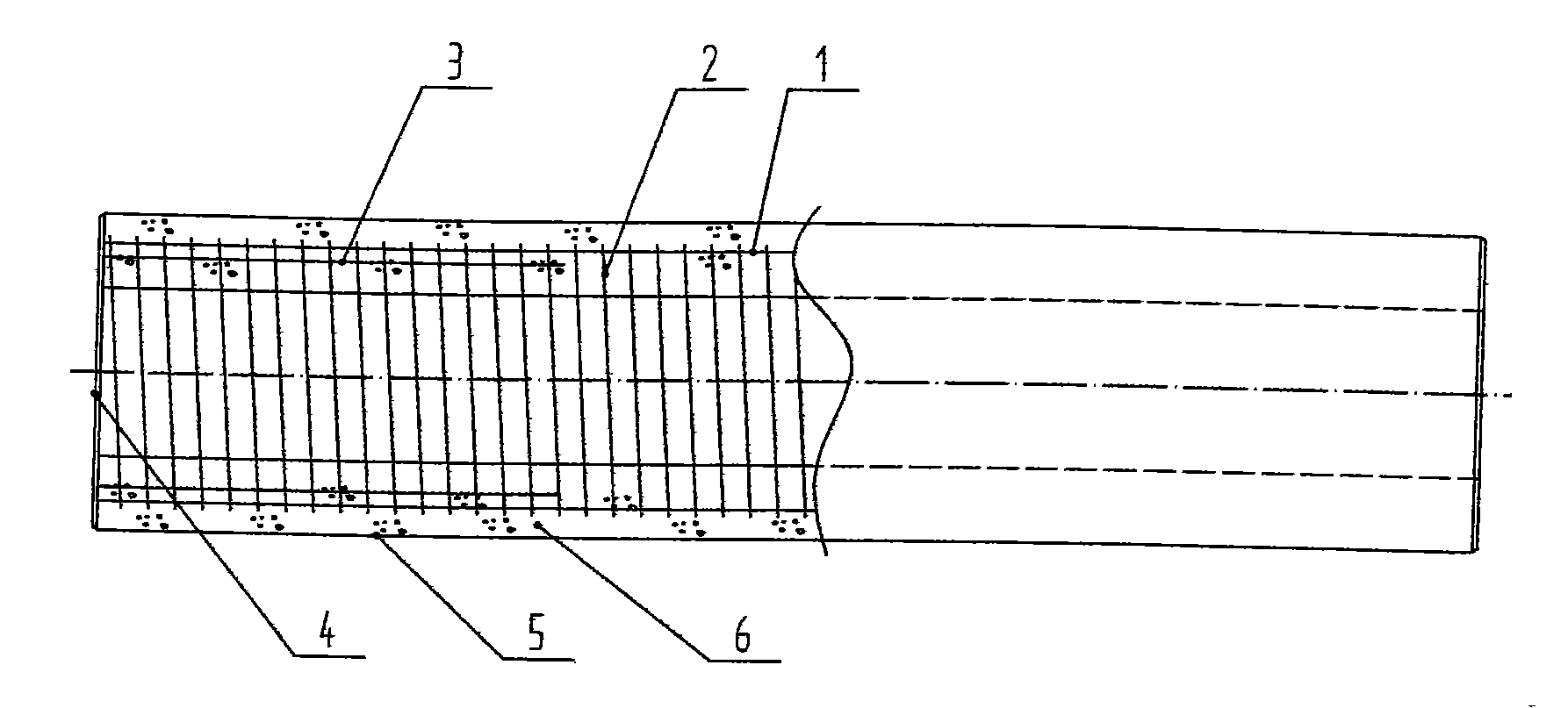

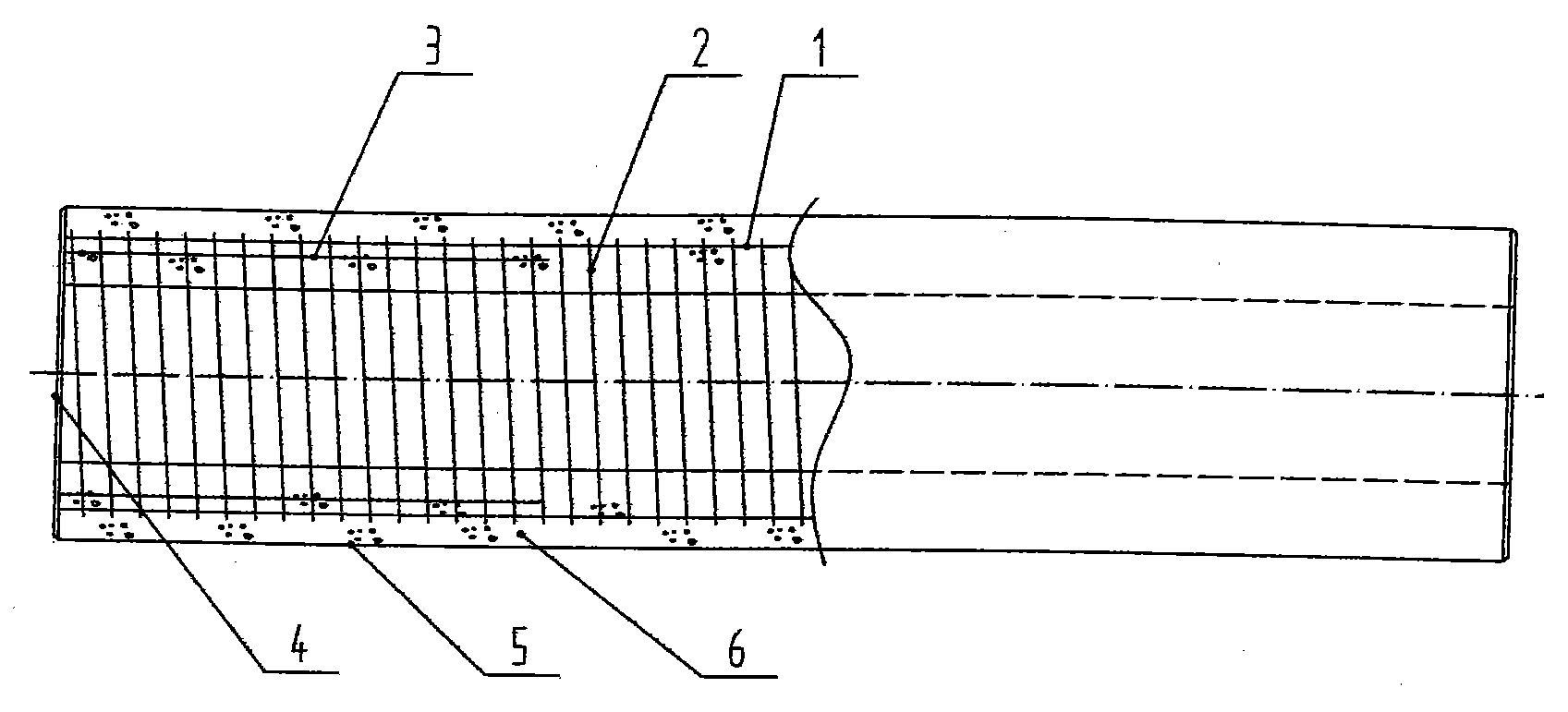

[0027] A method for producing pretensioned prestressed steel pipe concrete pipe piles, comprising the following steps in sequence:

[0028] (1) The steel pipe adopts the double submerged arc spiral welded pipe produced by the spiral welded pipe production line; in order to ensure the bonding force between the steel pipe and the concrete, the inner surface of the steel pipe is sprayed or projected, so that the surface cleanliness of the steel pipe is Sa2 1 / as stipulated in the national standard GB8923 Level 2, the roughness of the inner surface of the steel pipe is Ry=60~100;

[0029] (2) Carry out the anticorrosion treatment of the primer coating on the outer surface of the steel pipe;

[0030] (3) Weld the steel cage with the end plate with the central hole, and further weld the end plate with the steel pipe; the steel cage includes longitudinal prestressed reinforcement, and the longitudinal prestressed reinforcement is connected with spirally arranged steel wires, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com