Security protection system used for steel reinforced concrete support blasting engineering

A technology of reinforced concrete and blasting engineering, applied in the direction of blasting, etc., which can solve the problems of large impact on public safety in the surrounding environment, failure to eliminate the problems of blasting flying stones, steel pipes, and bamboo rafts, etc., and achieve bamboo material saving, high-quality blasting effect, and control The effect of blasting flying stone accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

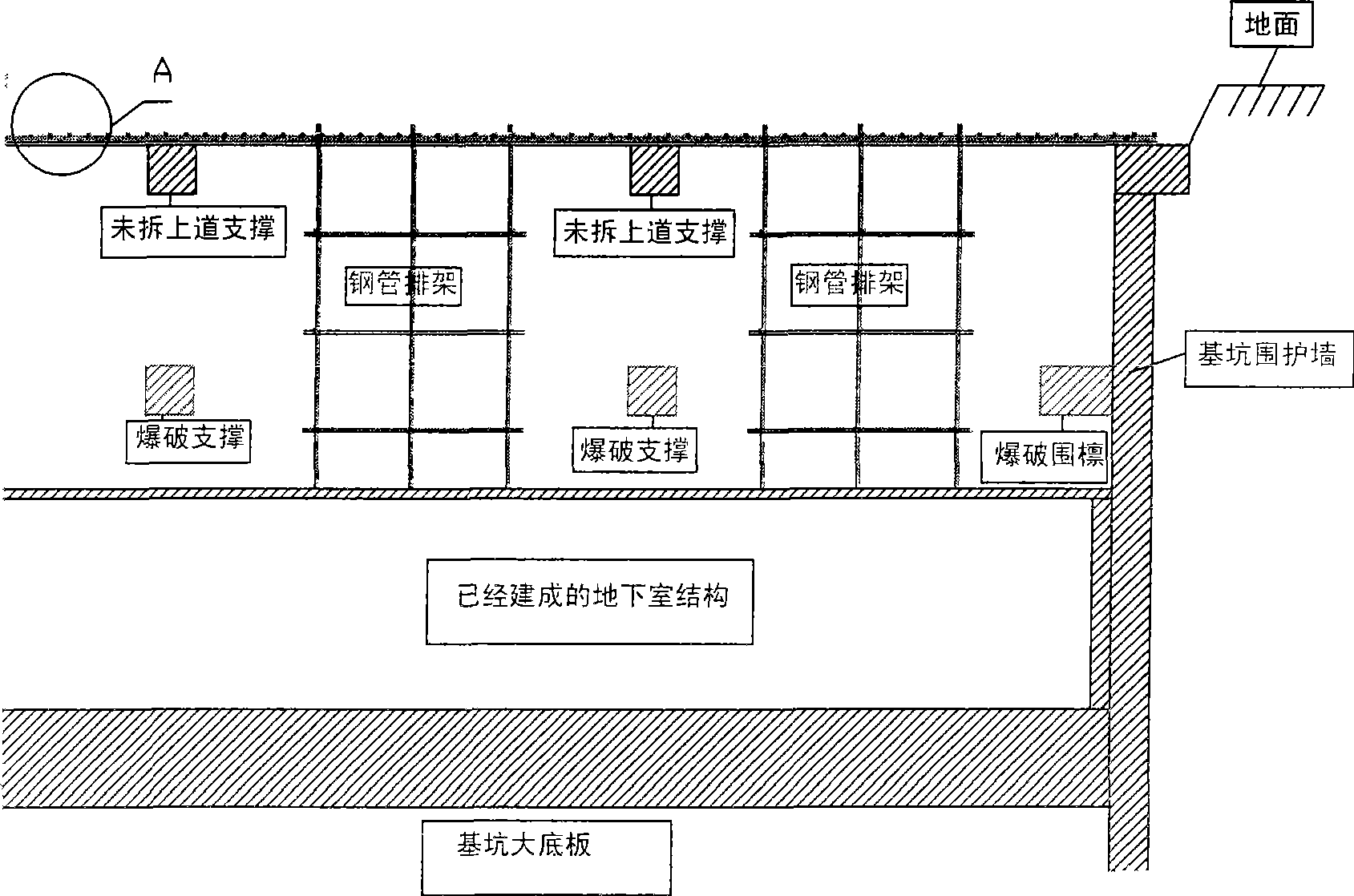

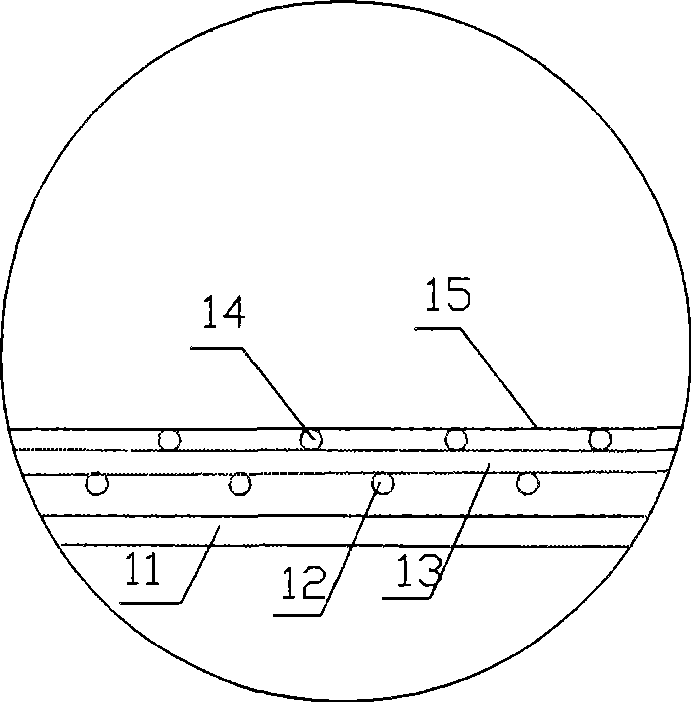

[0021] Figure 1 ~ Figure 2 It is a schematic diagram of the structure of a traditional safety protection net. In order to remove the redundant support of reinforced concrete in the foundation pit, it is necessary to set up a steel pipe support 11 first, set up a first steel pipe support surface 12 on the steel pipe support horizontal pipe frame, lay a bamboo raft 13 above the support surface, and set up a second steel pipe support surface 14 above the bamboo raft. , tie the construction safety net 15 above the second supporting surface. It takes a lot of labor to set up steel pipe supports and support surfaces before and after blasting.

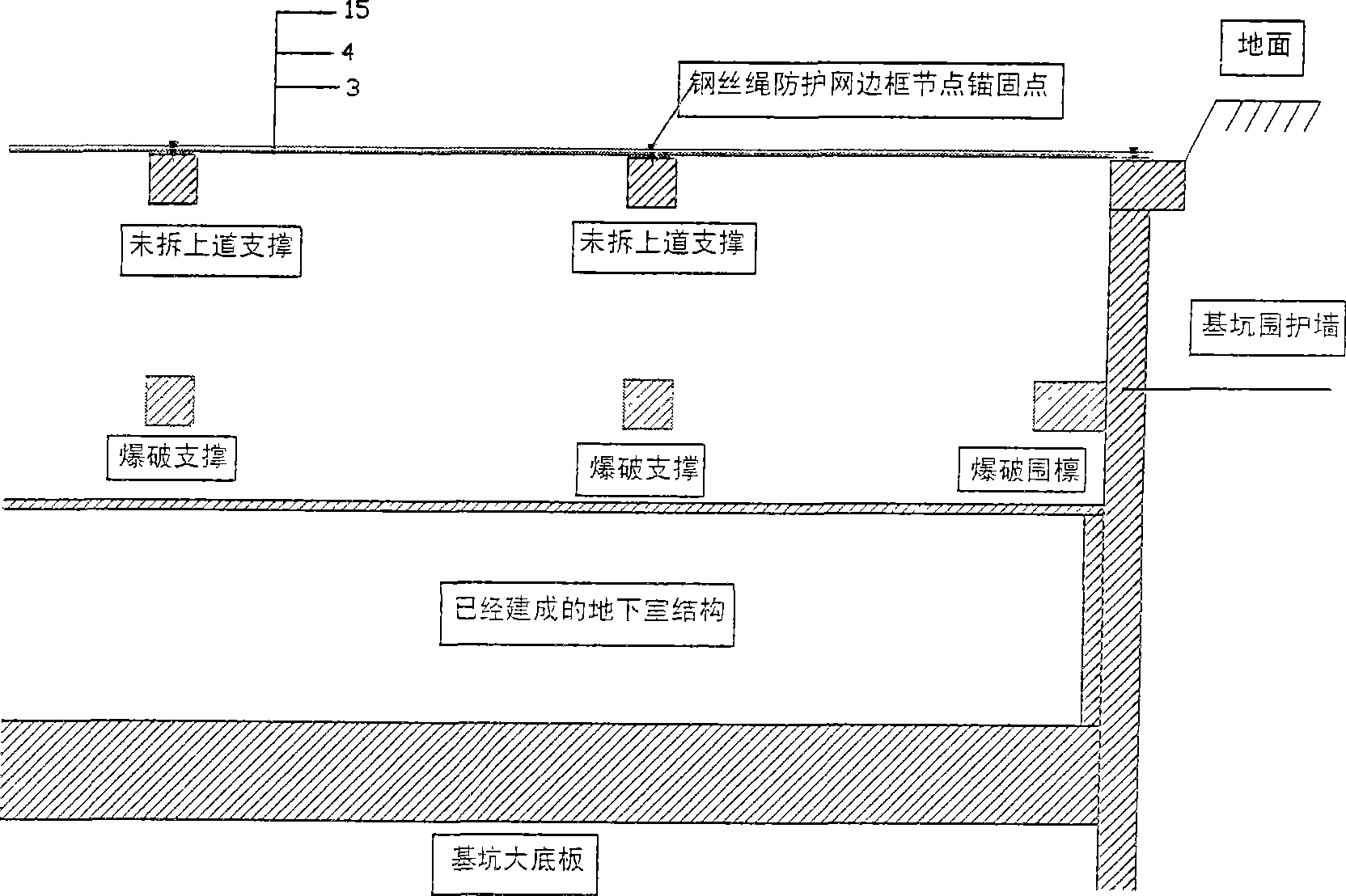

[0022] image 3 A schematic structural diagram of an embodiment of the present invention is given. A safety protection system for reinforced concrete support blasting engineering, including a building safety net 15, a rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com