Detonating tube cluster connection protection binding device

A detonating tube and cluster connection technology, applied in the field of blasting, can solve the problems of affecting the excitation and detonation effect, unstable explosion quality, time-consuming and laborious tying of cluster heads, etc., so as to increase the detonated area of the detonating tube, increase The effect of fast binding, reducing operation complexity and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

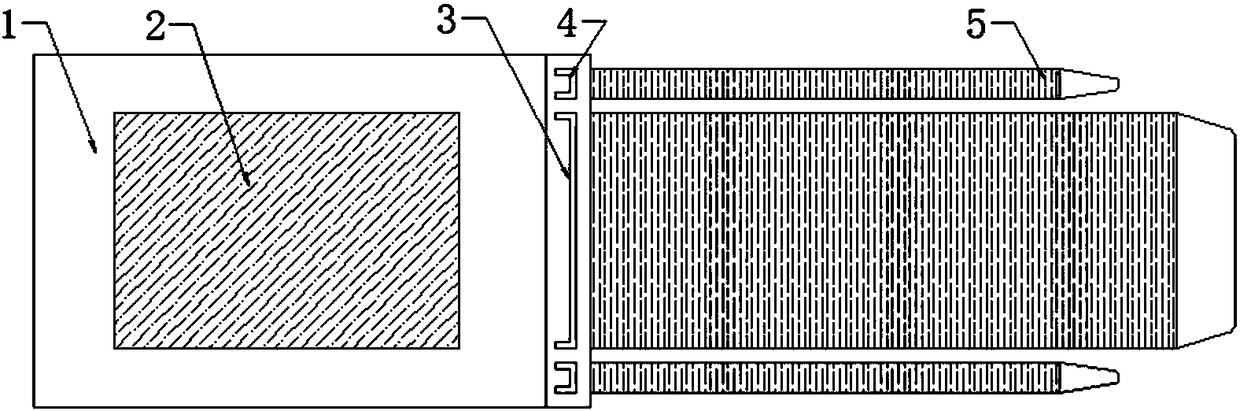

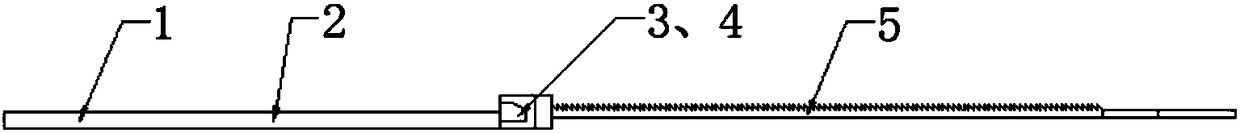

[0025] The embodiment of the present application provides a nonel cluster protection binding device to solve the technical problems in the prior art that the cluster head binding is time-consuming and laborious, and the instability of the explosion quality affects the excitation and transmission effects.

[0026] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embodiments can be combined without conflict.

[0027] see figure 1 and figure 2 , a protective binding device for det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com