Prediction method for dirt change trend of large condenser

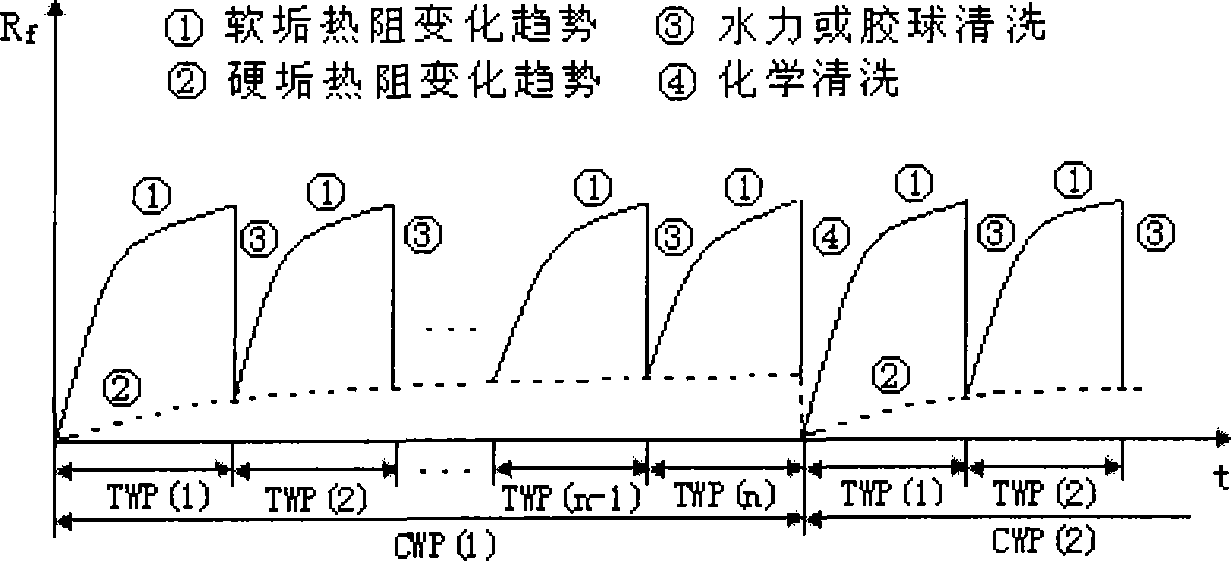

A technology of changing trends and prediction methods, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as difficulty in accurately predicting the changing trend of dirt, and only short-term changing trends can be predicted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

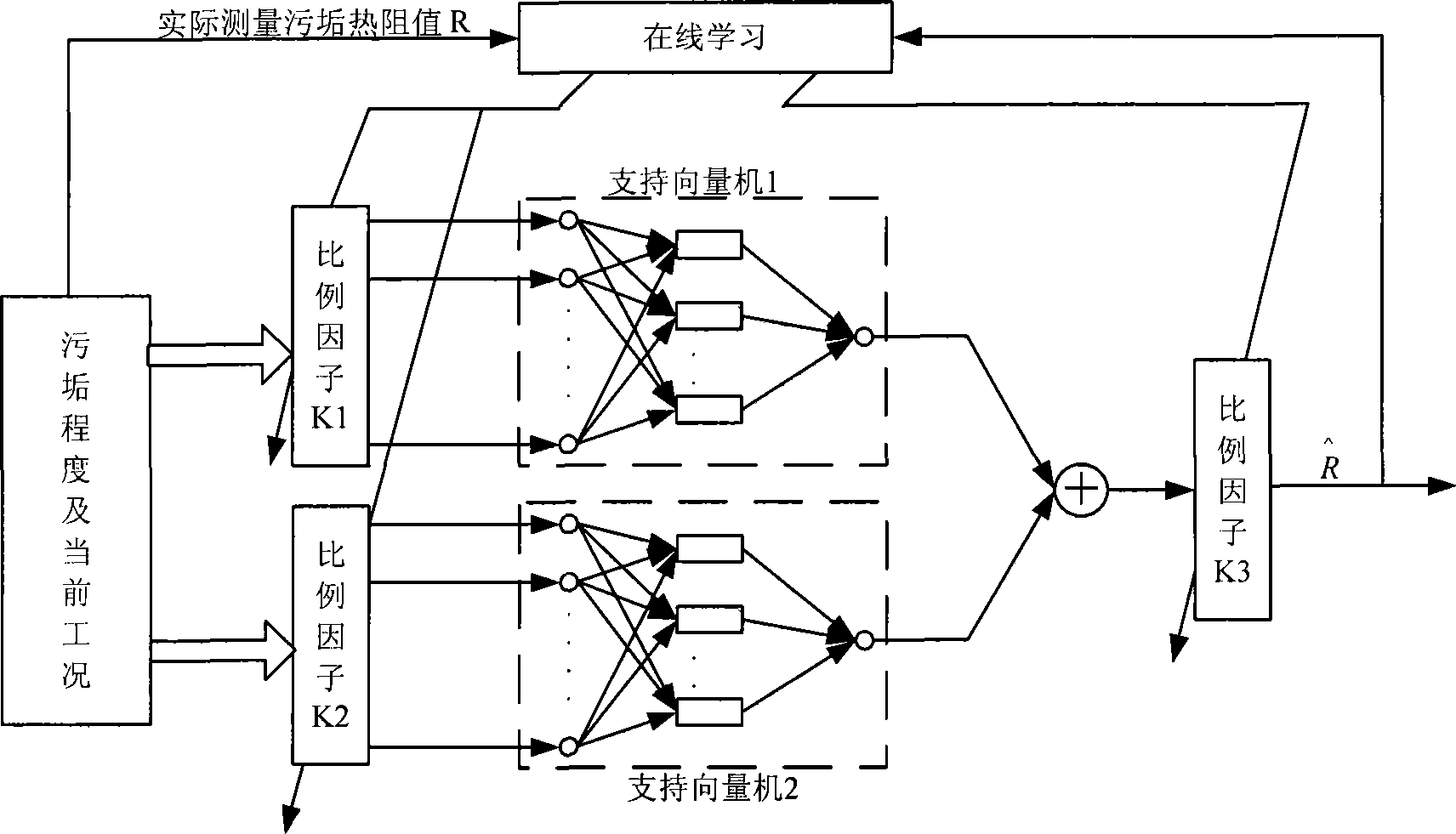

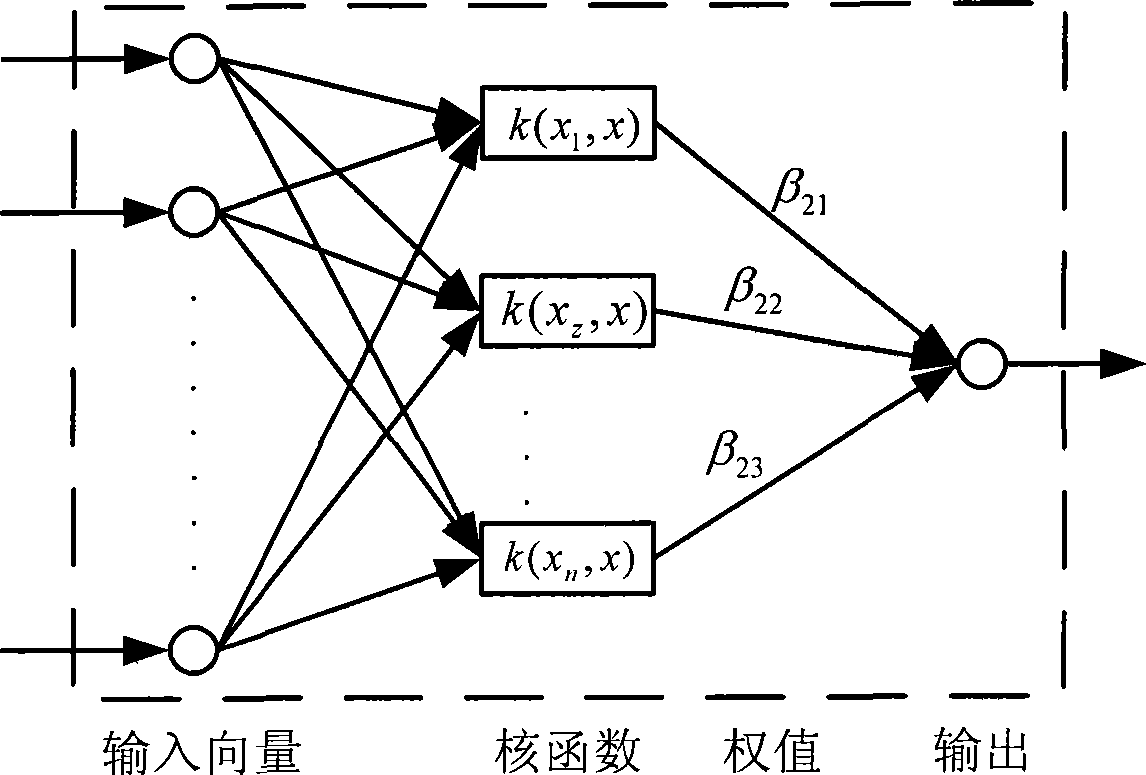

Method used

Image

Examples

Embodiment 1

[0110] Example 1: Steam flow rate, steam temperature, cooling water inlet temperature, cooling water outlet temperature, cooling water flow rate, turbidity, hardness and other operating parameters can be converted into electrical signals through corresponding sensors, and then stored in the in the computer. Among them, the steam flow is measured by the vortex flowmeter; the thermal resistance temperature sensor is used to measure the steam temperature, the cooling water inlet temperature and the cooling water outlet temperature; the flow rate sensor is used to measure the flow rate of the cooling water; the turbidity sensor is used to measure the turbidity of the water; the electrode sensor is used to measure the hardness of the water . The armored thermocouple is buried in the heat exchange tube wall, and the fouling thermal resistance measured by the thermal resistance method is used to describe the fouling degree of the condenser. For the condenser with a capacity of 300MW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com