Fluid dynamic bearing apparatus and process for manufacturing the same

A fluid bearing and radial bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of insufficient lubricating oil and reduced lubricating oil, and achieve the effect of curbing lubricating oil immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

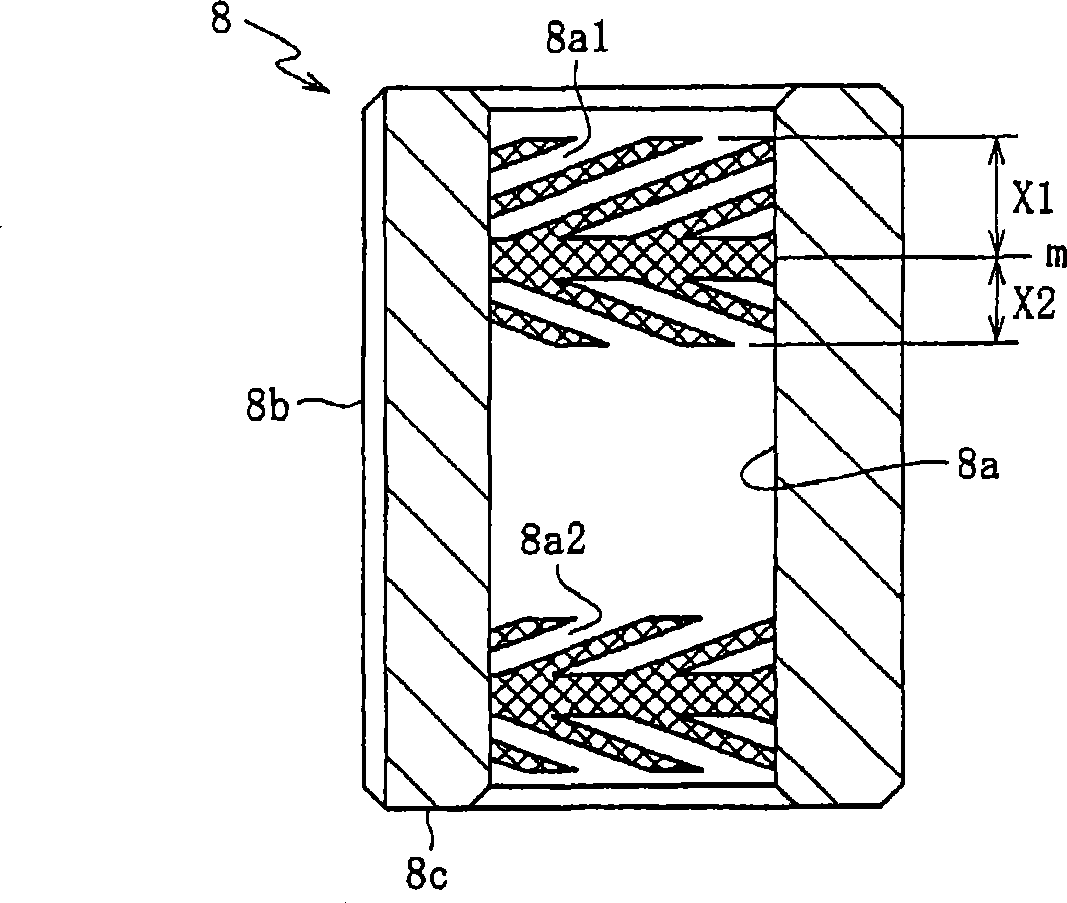

[0073] In order to verify the effect of the present invention, the resin composition composed of many finely divided carbon fibers with different binders or no binders is required for the housing part of the fluid bearing device. The oil absorption resistance was evaluated.

[0074] Specifically, formed by the resin composition shown in Fig. 7 Image 6 The illustrated case portion 27 evaluates the oil absorption resistance of the resin case portion by measuring the amount of drop in the oil level in the sealed space S in the fluid bearing device 21 equipped with the case portion 27 . When the drop in oil level is less than 0.03 mm 10 days after the start of the measurement, and thereafter (after 20 days) there is no tendency to drop the oil level, the casing meets the oil absorption resistance requirements. Here, five kinds of thermoplastic resins such as PPS and LCP are used as the base resin. Carbon fibers used as fillers are carbon fibers using epoxy resins, nylon resins,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com