Medical soft polychloroethylene plastic without o-benzene series plasticiser

A technology of phthalic plasticizers and soft polyvinyl chloride, which is applied in the field of medical soft polyvinyl chloride plastics without phthalic plasticizers and its production, can solve the problems of DOP dissolution, adverse effects on human body and environment, etc. , to achieve the effect of improving low temperature performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

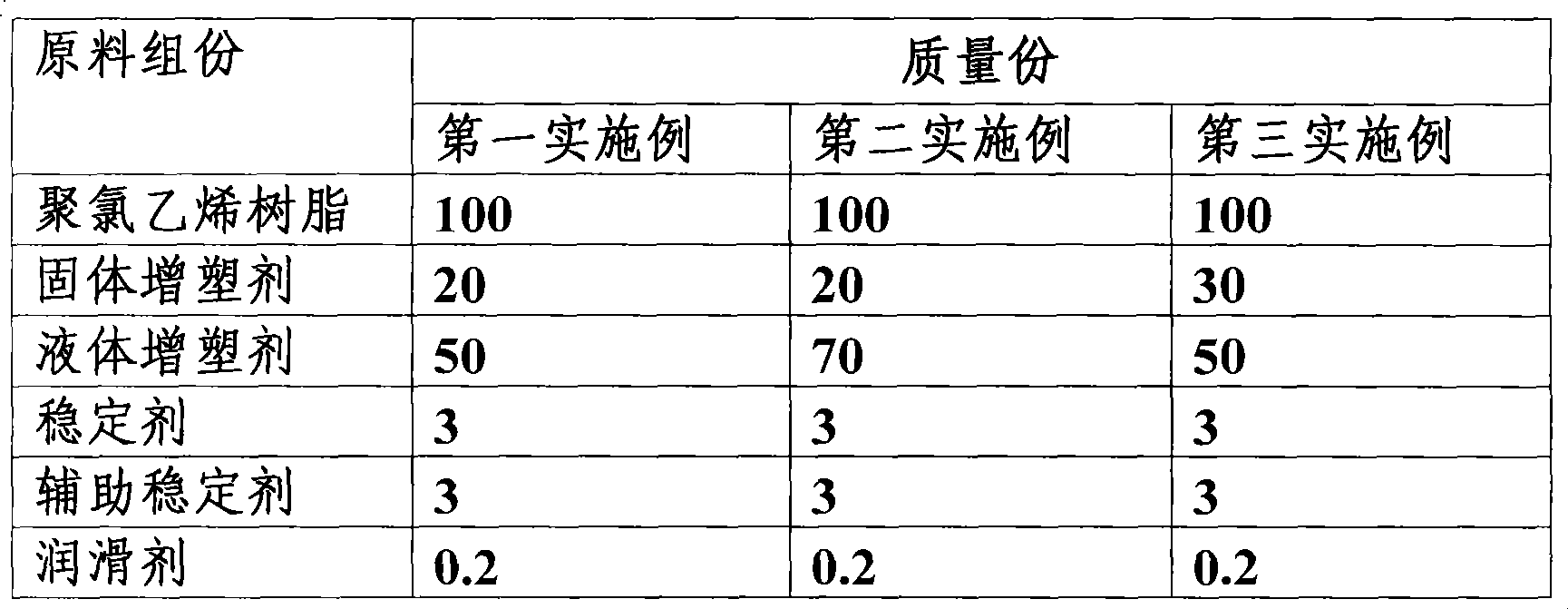

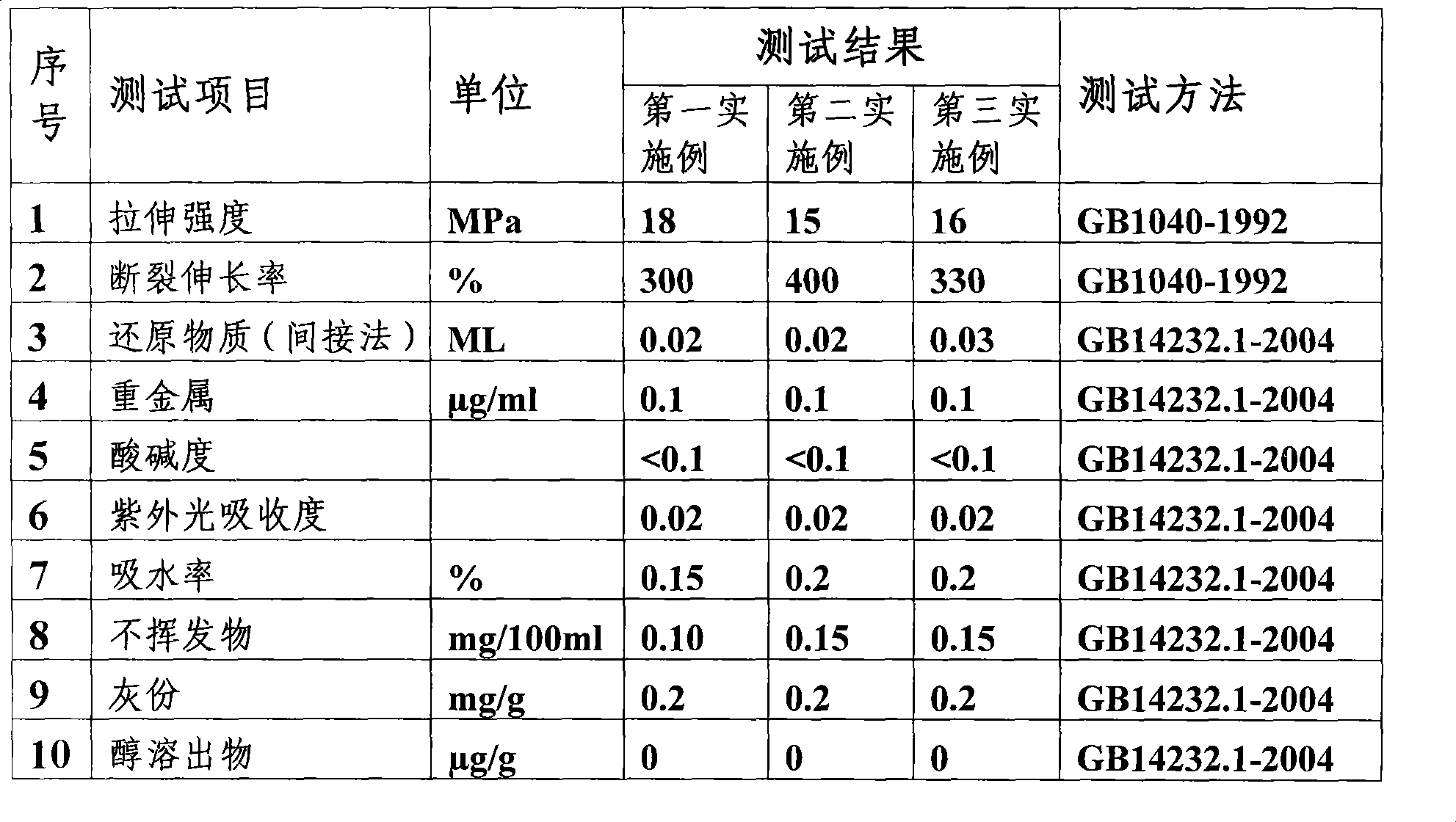

[0015] The raw material components of the medical soft polyvinyl chloride plastic that does not contain o-phthalic plasticizers are selected and accurately weighed according to the three formulas in the table below.

[0016]

[0017] In the above formulation, the polyvinyl chloride resin is suspension polymerized to obtain PVC with a polymerization degree of 1000, wherein the residual amount of vinyl chloride monomer is less than 1 mg / kg, and the viscosity number of the polyvinyl chloride resin is 50ml / g-160ml / g. The solid plasticizer is ethylene butyl acrylate carboxyl copolymer, ethylene / n-butyl acrylate / carbonmonoxide(E / nBA / CO)copolymer. The stabilizer is a medical-grade powdery or paste-like compound calcium-zinc stabilizer, wherein the mass percentages of calcium and zinc are respectively less than 1.5%. The auxiliary stabilizer is epoxidized soybean oil, its flash point is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com