Vacuum pumping micro-leak repair method

A technology of vacuuming and micro-leakage, which is applied in the field of repairing micro-leakage, can solve the problems of low sensitivity, long time, easy surface peeling, etc., and achieve the effect of improving the repair effect and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

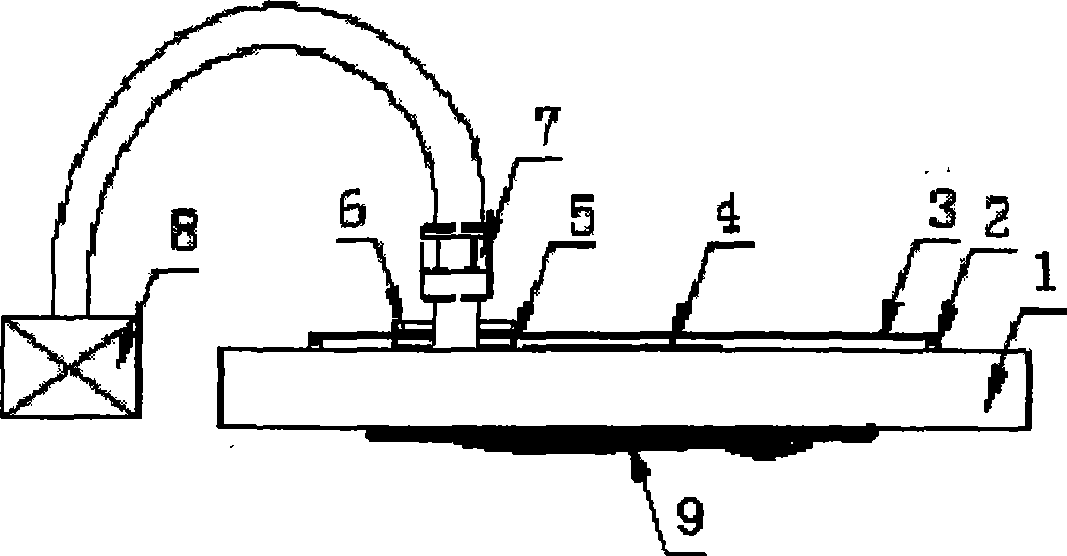

[0011] The specific implementation steps are as follows:

[0012] 1. Prepare the repair tools and site, clean and dry the surface of the object 1 to be repaired;

[0013] 2. Paste double-sided tape 2 with a width of 6 mm to 10 mm around the surface of the repaired object 1, and cover the repaired part of the repaired object 1 with white felt cloth 4. The function of the white felt cloth 4 is to display the repair The position of the micro-leakage of the object 1, and protect the vacuum bag 3 from being damaged by the sharp point in the repair object 1;

[0014] 3. Use scissors to cut out the hole for installing the vacuum joint 5 on the vacuum bag 3, and put it into the vacuum joint 5. Use a wrench to lock the threaded washer 6 and the vacuum joint 5 to ensure that the vacuum joint 5 is in good contact with the vacuum joint 5. The bag 3 interface is sealed; the hose connector 5 is connected to the hose on the vacuum pump 8 with the hose connector 7.

[0015] 4. After tearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com