Low temperature tenacity excellent low yield ratio high intensity steel plate for welding heat influenced part and mother plate, and manufacturing method thereof

A steel plate and quality technology, applied in the field of low yield ratio and high tension steel plate, can solve the problems of inability to achieve safety and parallelism, and achieve the effect of excellent low temperature toughness and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

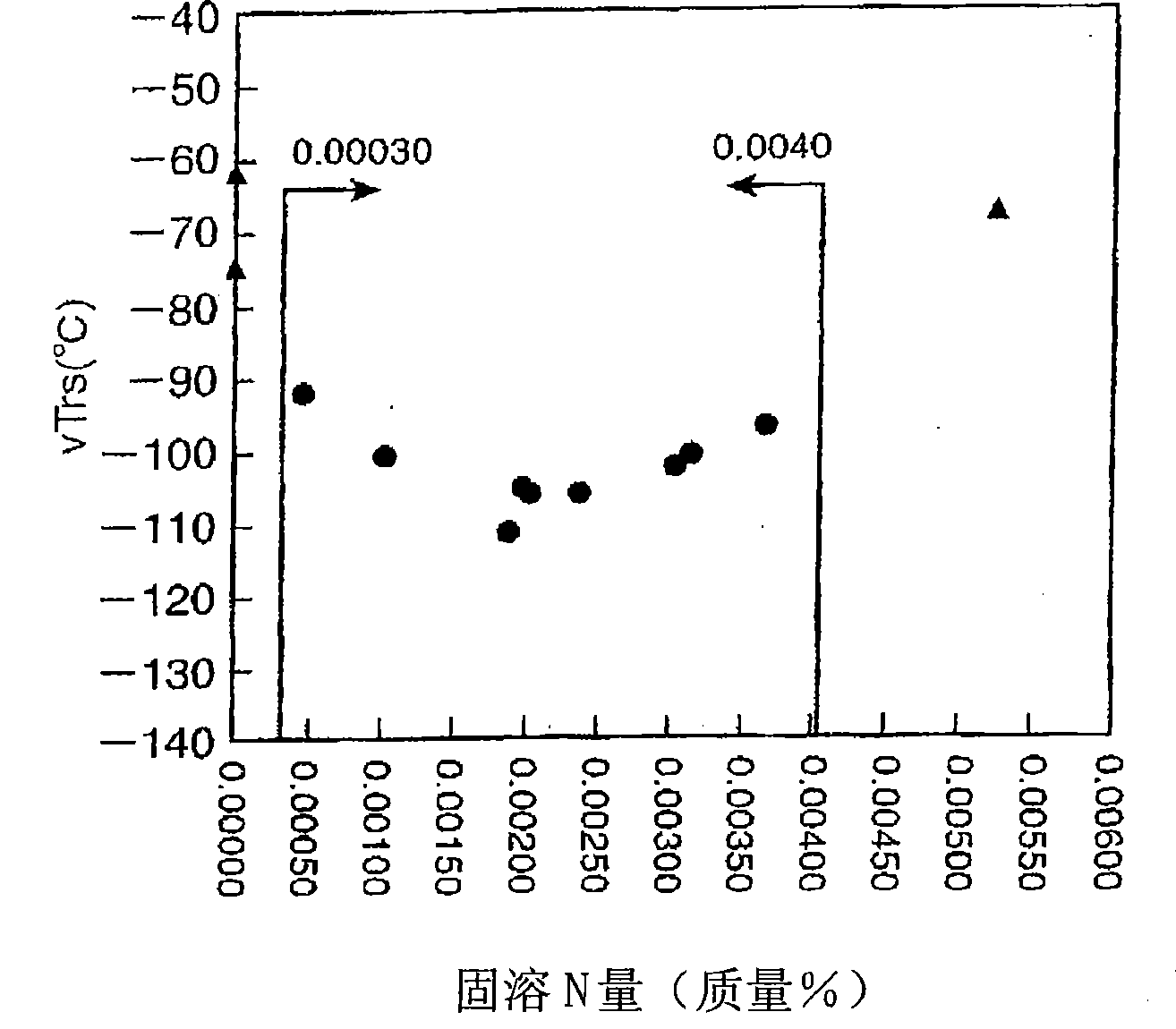

[0020] The inventors of the present invention have conducted studies from various angles in order to realize a high-tensile steel sheet excellent in low-temperature toughness of the HAZ and the base material. As a result, it was found that in order to ensure the toughness of the HAZ, if the C is set to be less than 0.09% and the Si is set to be less than 0.25%, and the chemical composition is adjusted, the bands composed of TiN and BN can be produced to the maximum extent. The effect of refining the grains in the austenite grains, and allowing a specified amount of solid solution N to exist in the island martensite (MA), can stabilize the retained austenite (retained γ), and in MA By ensuring a predetermined amount of residual γ in the steel sheet, the strength and toughness of the steel plate (base material) can be balanced, and the present invention has been completed.

[0021] In the high-tensile steel sheet of the present invention, in the microstructure at the t / 4 (t: pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com