Liquid level control valve

A liquid level control, two-position three-way valve technology, applied in multi-way valves, valve devices, valve details, etc., can solve problems such as clogging of moving parts in water, sensors or liquid level switches requiring power supply, etc., to achieve liquid level The effect of control, simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

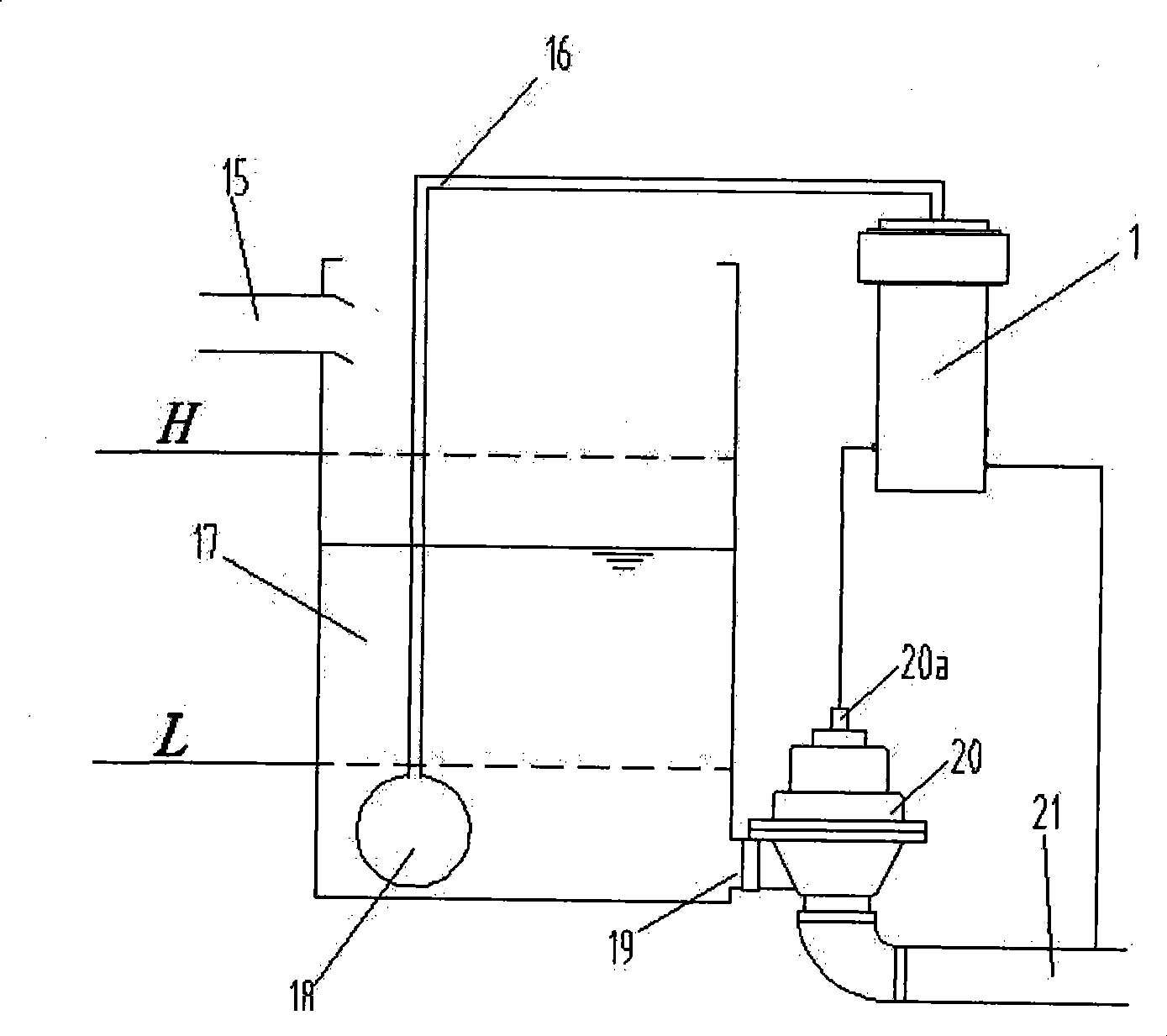

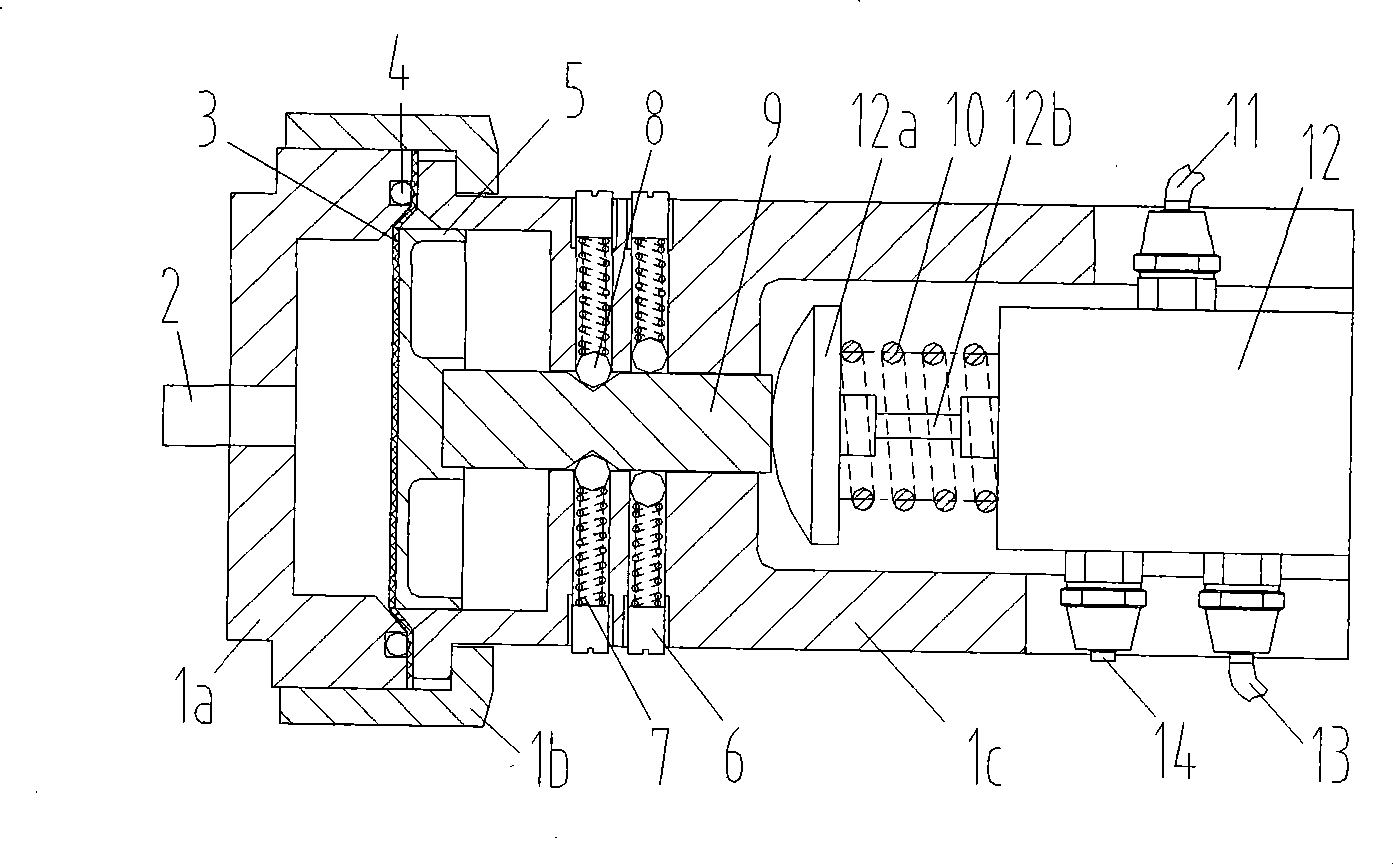

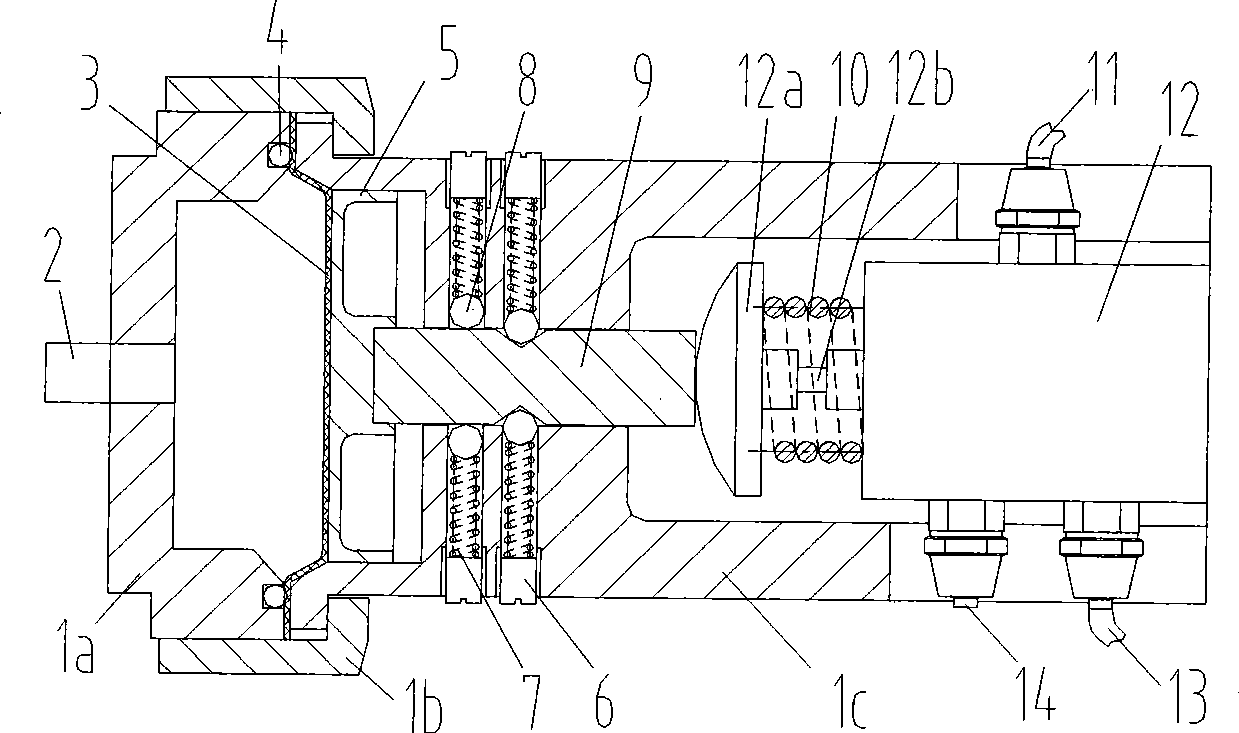

[0016] Such as figure 1 , figure 2 As shown, the water collection tank 17 collects and stores the sewage discharged by the user, the water collection tank inlet 15 is connected to the user's sewer pipe, the water collection tank outlet 19 is connected to the vacuum interface valve 20, and the air bag 18 is placed at the bottom of the water collection tank; the liquid level control valve 1 passes the liquid level sensor The pipe 16 communicates with the air bag 18, the interface valve joint 11 of the liquid level control valve 1 is connected to the interface valve control hole 20a, and the air source joint 13 is connected to the vacuum drainage pipe 21; the vacuum interface valve 20 is a normally closed negative pressure pneumatic valve, and its control hole 20a The vacuum interface valve 20 is opened when the negative pressure is connected, and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com