Hypergravity dust-removing or decoking technique for gas and device

A super-gravity, gas-fired technology, applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of dust removal, poor decoking effect, large floor space, and high input cost, and achieve an improved effective ratio. The effect of surface area, small footprint, and low equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

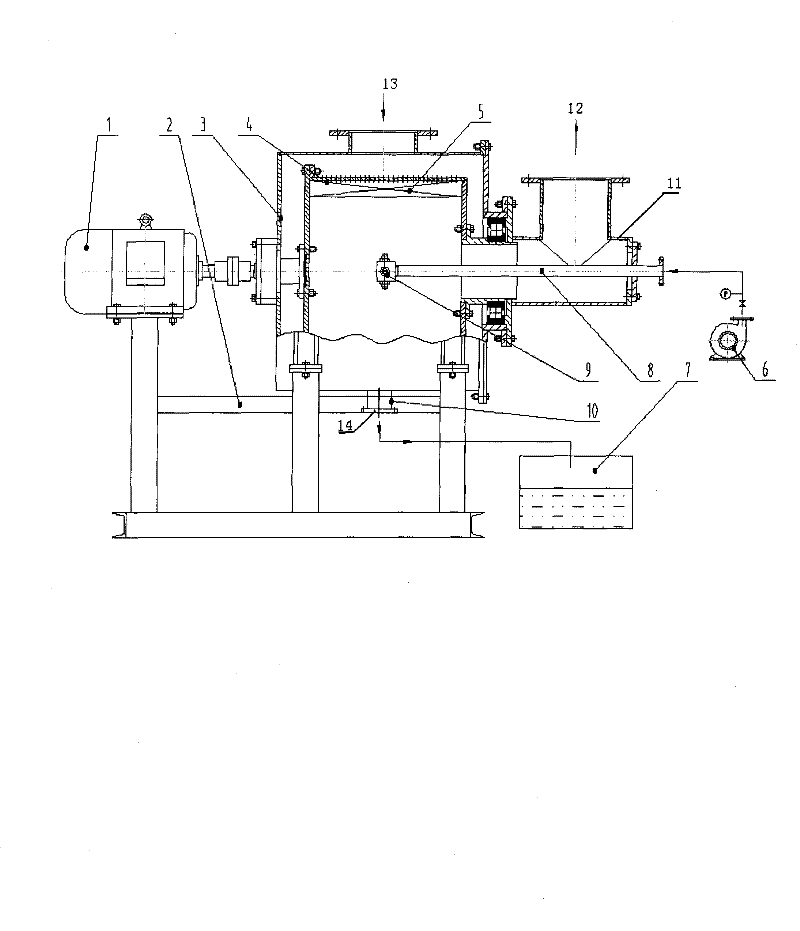

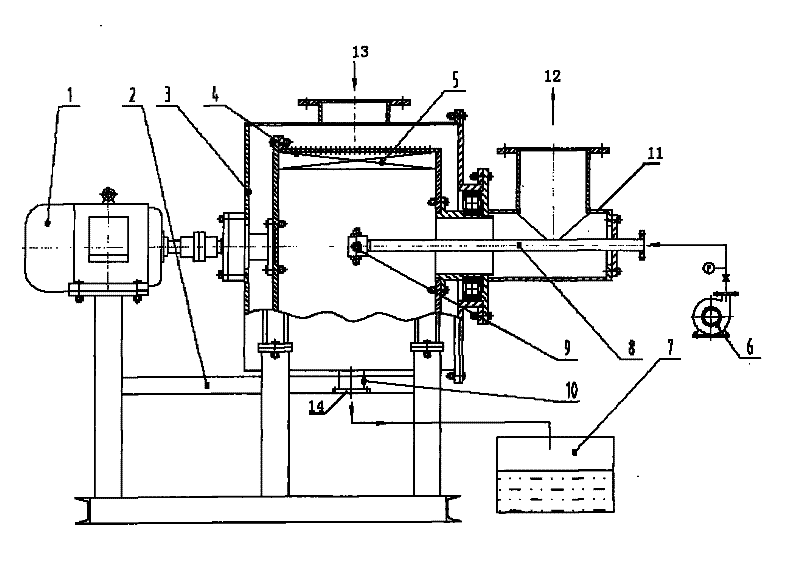

[0015] A gas supergravity dedusting or decoking process includes inputting gas and liquid into a supergravity dedusting or decoking device, and outputting after dedusting or decoking. The gas enters the inner cavity from the outer circumference of the rotating rotor 4 equipped with fillers or screens 5 in the supergravity dust removal or degumming device, flows from outside to inside through the fillers or screens 5, and flows out from the middle. The liquid flows in from the liquid inlet pipe 8, and is sprayed into the inner cavity of the rotating rotor 4 by the nozzle 9 in the center of the rotating rotor 4. Under centrifugal action, the gas is in the opposite direction from the inside to the outside, and passes through the filler or wire mesh 5 in the inner cavity of the rotor 4. Outflow from the bottom.

[0016] The gas and the liquid flow counter to each other under the high-speed rotation of the rotating rotor 4, and the liquid contacts the gas in the curved flow path at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com