Bismuth-based dielectric material for microwave tuning and preparation thereof

A dielectric material, bismuth-based technology, applied in the field of microelectronic materials, can solve the problems of increased dielectric loss, etc., and achieve the effect of low dielectric loss and high dielectric tuning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

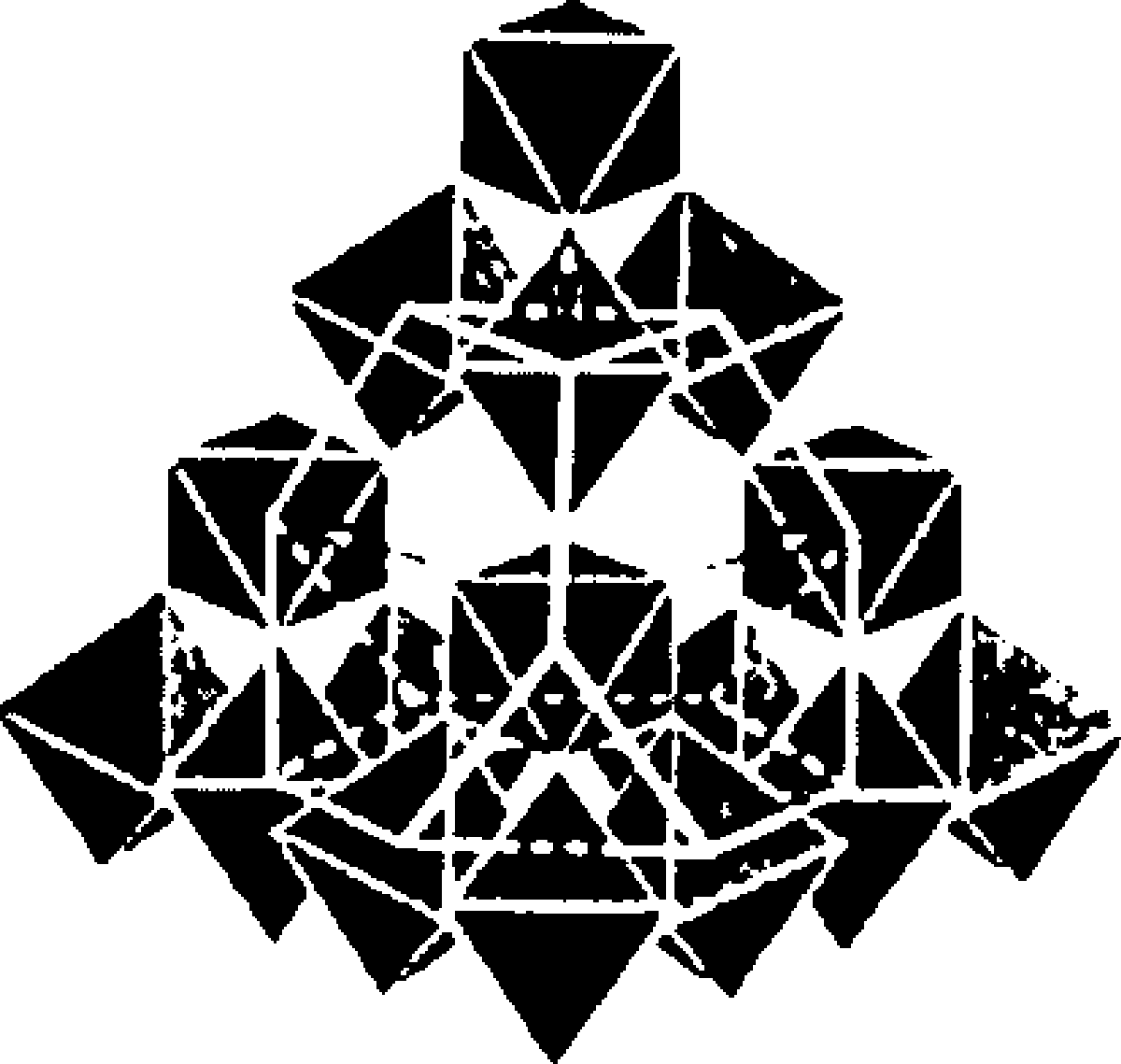

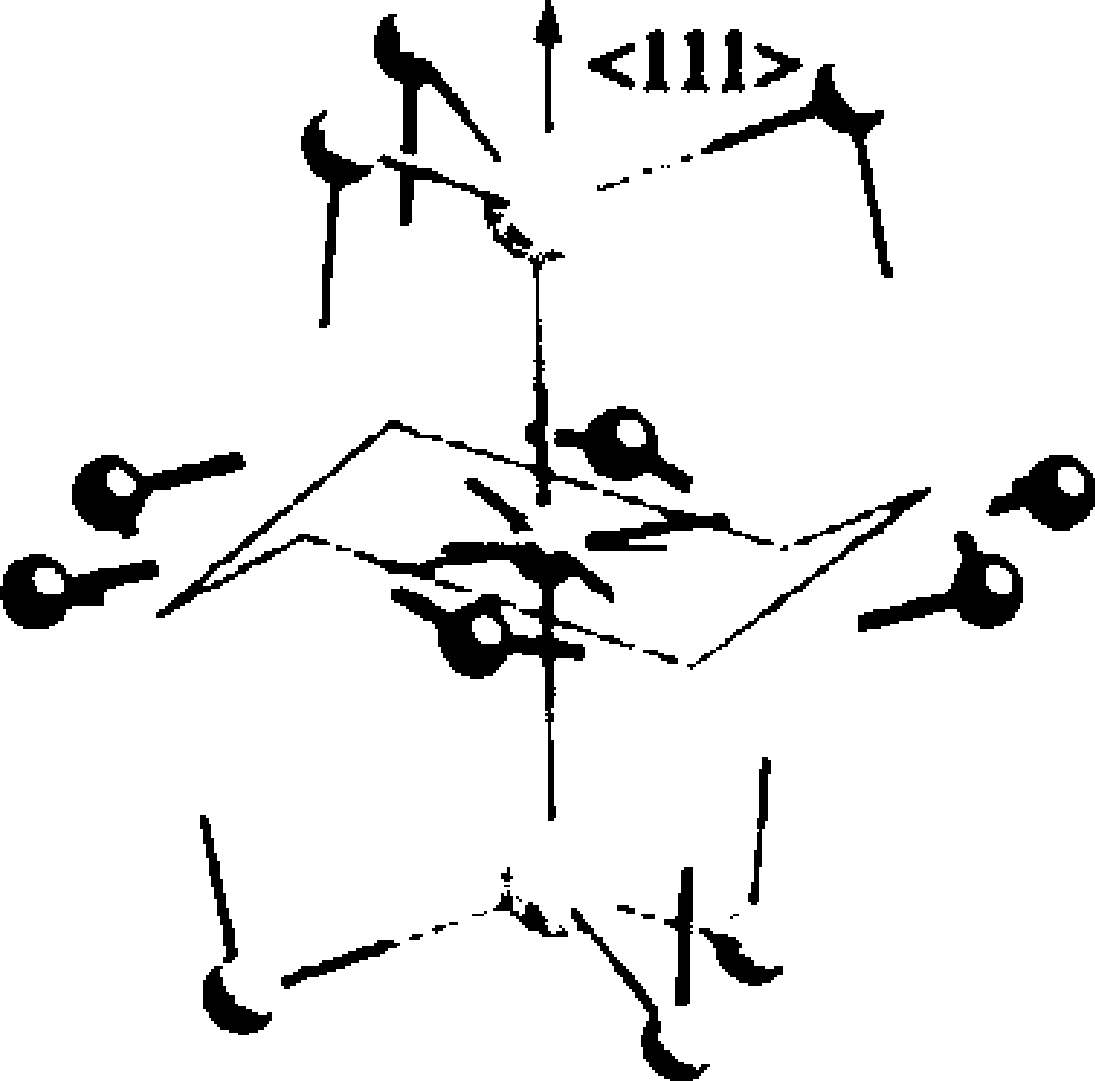

Image

Examples

Embodiment

[0030] In this example, Mg is used to replace Zn in the bismuth zinc niobate (BZN) material, and the chemical composition is Bi 1.5 MgNb 1.5 o 7 (BMN) bismuth magnesium niobate material. Mg in this material 2+ Ions have a higher ratio than Zn 2+ The smaller the radius, it is inferred that the material should have a higher dielectric tuning rate than the BZN material. The BMN thin film was prepared by radio frequency magnetron sputtering, and the dielectric properties of the BMN thin film were studied. It was found that the BMN thin film material has the characteristics of high dielectric tuning rate and low dielectric loss, and is suitable for voltage-controlled microwave frequency. An excellent dielectric material for components.

[0031] The dielectric film preparation process is as follows:

[0032] 1. Preparation of bismuth magnesium niobate ceramic materials.

[0033] Preparation of Bi 1.5 MgNb 1.5 o 7 Ceramic materials use a solid-state reaction method. Analyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com