Method for preparing dielectric tunable complex-phase microwave ceramic material by hydrothermal method through in-situ synthesis

A technology of microwave ceramics and in-situ compounding, which is applied in the direction of circuits, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of low interface bonding strength, coarse particles, thermodynamic instability, etc., and achieve easy Effect of grain size, low production cost, and improved microwave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

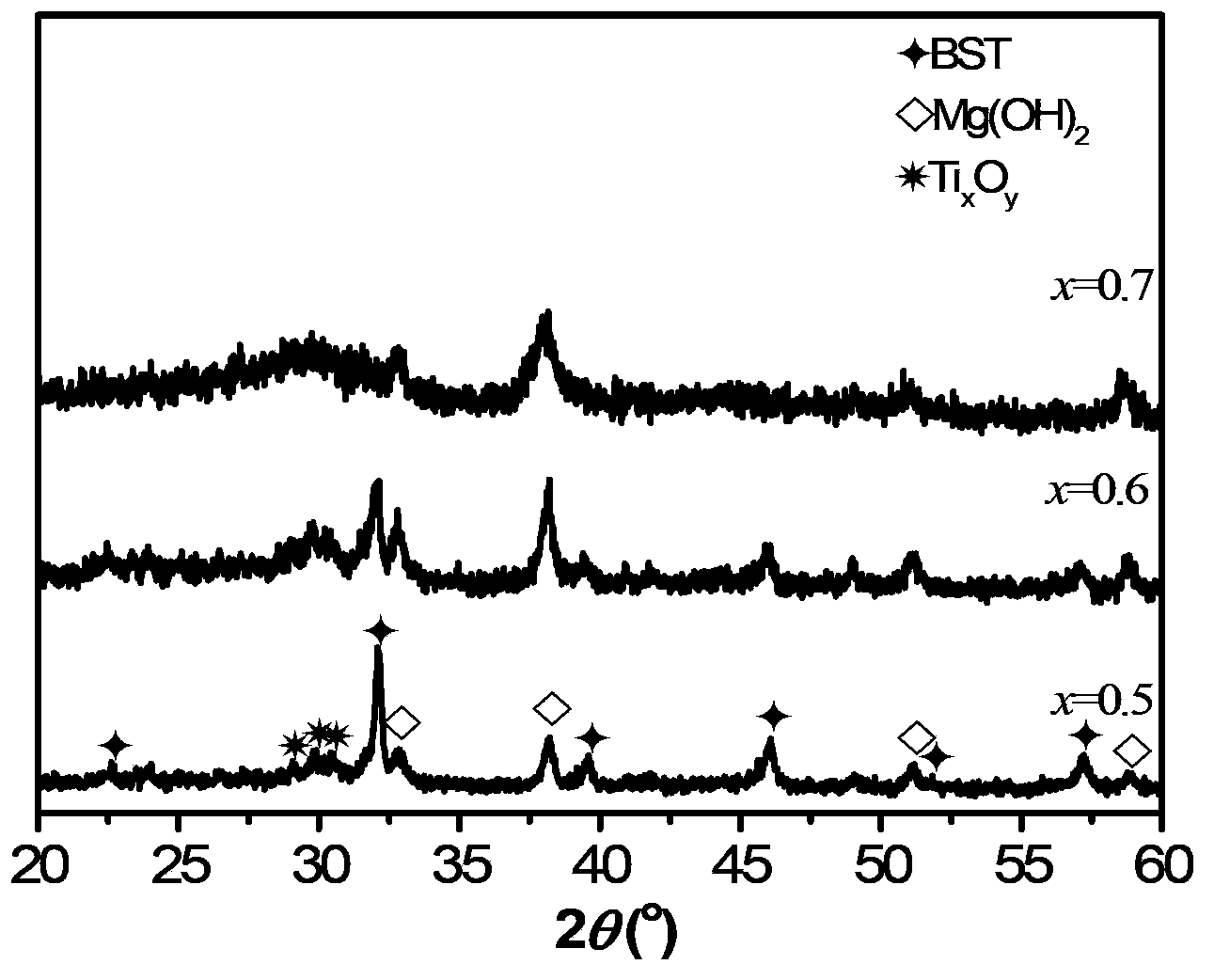

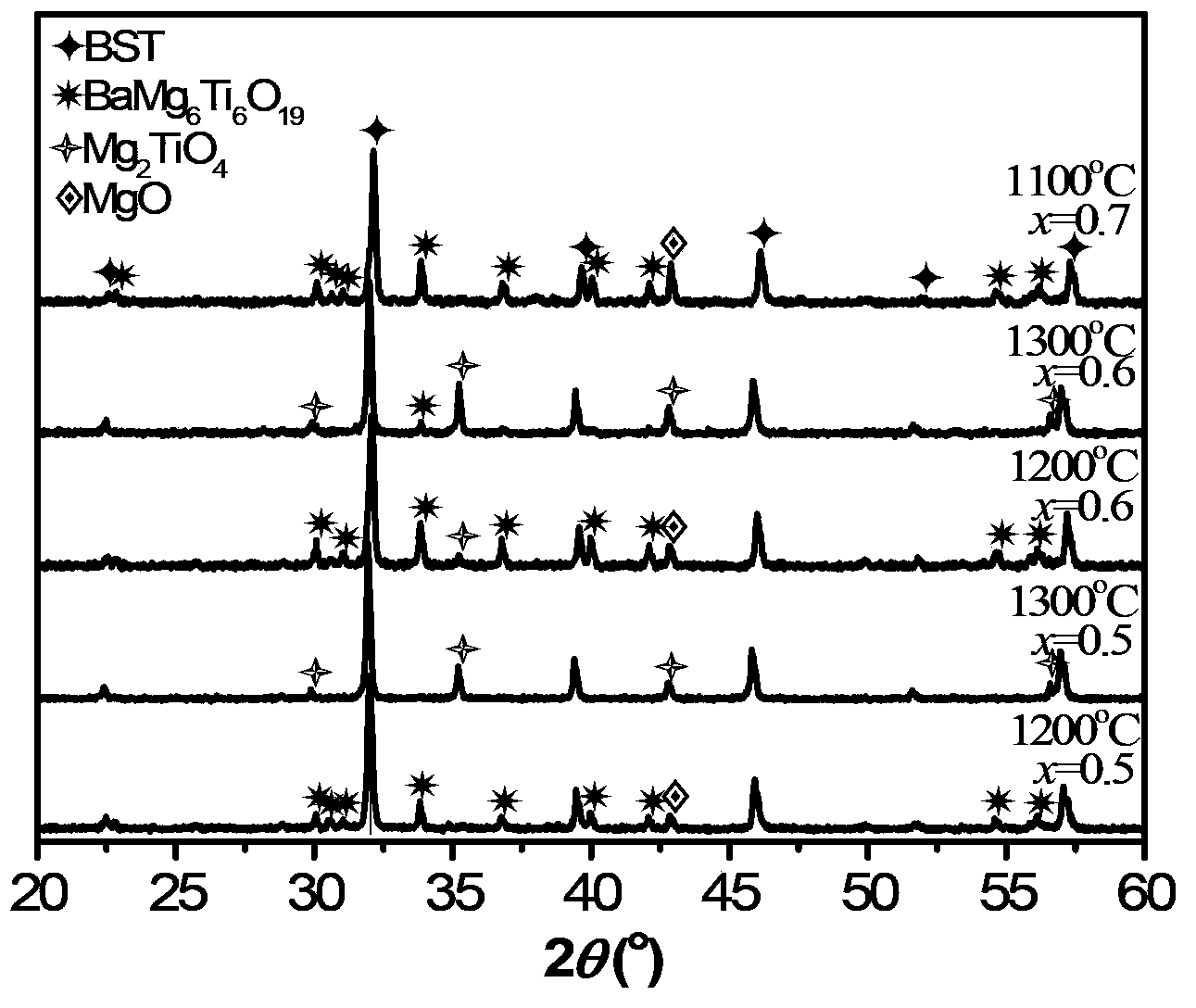

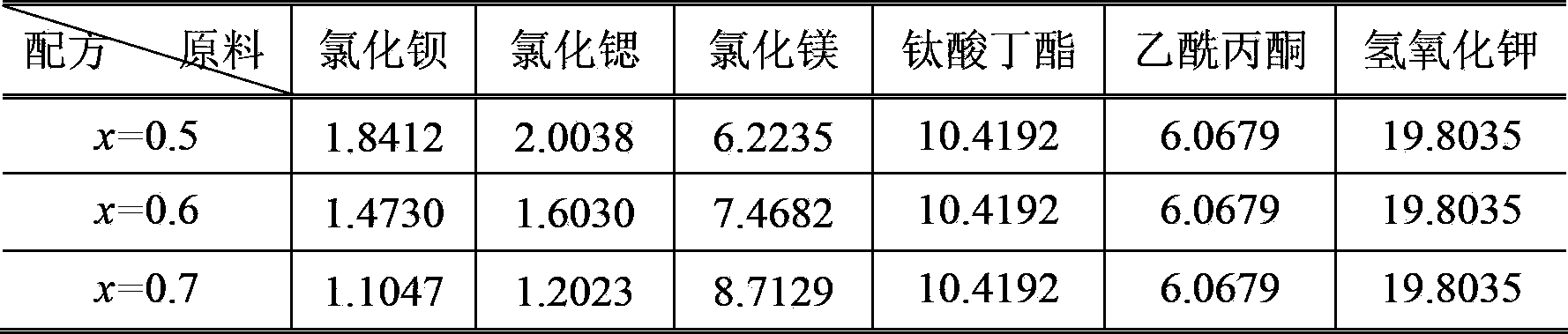

[0039] One part of 0.0075mol of BaCl 2 and SrCl 2 , 0.0300mol of MgCl 2 , a part of 0.0060mol of BaCl 2 and SrCl 2 , 0.0360mol of MgCl 2 , a part of 0.0045mol BaCl 2 and SrCl 2 , 0.0420mol of MgCl 2 , were dissolved in 30ml deionized water to prepare Ba, Sr, Mg solutions; 0.0300molC 16 h 36 o 4 Ti is dissolved in 0.0600molC 5 h 8 o 2 Form the Ti solution in the middle; Mix the three kinds of Ba, Sr and Mg solutions prepared above with the Ti solution respectively, stir evenly, and prepare (1-x)Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution; then the KOH solution formed by dissolving 0.3000mol KOH in 100ml deionized water was dropped into (1-x) Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution, mixed and stirred to prepare 160ml, poured into a 200ml hydrothermal kettle and reacted hydrothermally at a temperature of 180°C for 24 hours, washed and filtered to obtain powder;

[0040] BaCl 2 , SrCl 2 , MgCl 2 、C ...

Embodiment 2

[0044] A portion of 0.0075mol of Ba(NO) 2 and Sr(NO) 2 , 0.0300mol of Mg(NO) 2 , a 0.0060mol Ba(NO) 2 and Sr(NO) 2 , 0.0360mol of Mg(NO) 2 , a 0.0045mol Ba(NO) 2 and Sr(NO) 2 , 0.0420mol of Mg(NO) 2 , were dissolved in 30ml deionized water to prepare Ba, Sr, Mg solutions; 0.0300molC 16 h 36 o 4 Ti is dissolved in 0.0600molC 5 h 8 o 2 Form the Ti solution in the middle; Mix the three kinds of Ba, Sr and Mg solutions prepared above with the Ti solution respectively, stir evenly, and prepare (1-x)Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution; then the KOH solution formed by dissolving 0.3000mol KOH in 100ml deionized water was dropped into (1-x) Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution, mixed and stirred to prepare 160ml, poured into a 200ml hydrothermal kettle and reacted hydrothermally at a temperature of 180°C for 24 hours, washed and filtered to obtain powder;

[0045] Ba(NO 3 ) 2 , Sr(NO 3 ) 2 ,...

Embodiment 3

[0049] A part of 0.0075mol of Ba(CH 3 COO) 2 and Sr(CH 3 COO) 2 , 0.0300mol of Mg(CH 3 COO) 2 , a part of 0.0060mol of Ba(CH 3 COO) 2 and Sr(CH 3 COO) 2 , 0.0360mol of Mg(CH 3 COO) 2 , a part of 0.0045mol of Ba(CH 3 COO) 2 and Sr(CH 3 COO) 2 , 0.0420mol of Mg(CH 3 COO) 2 , were dissolved in 30ml deionized water to prepare Ba, Sr, Mg solutions; 0.0300molC 16 h 36 o 4 Ti is dissolved in 0.0600molC 5 h 8 o 2 Form the Ti solution in the middle; Mix the three kinds of Ba, Sr and Mg solutions prepared above with the Ti solution respectively, stir evenly, and prepare (1-x)Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution; then the KOH solution formed by dissolving 0.3000mol KOH in 100ml deionized water was dropped into (1-x) Ba 1-n Sr n TiO 3 -xMg 2 TiO 4 (x=0.5, 0.6 and 0.7) precursor solution, mixed and stirred to prepare 160ml, poured into a 200ml hydrothermal kettle and reacted hydrothermally at a temperature of 180°C for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com