Rubber liner with lubricating oil and manufacturing method thereof

A technology for a rubber bushing and a manufacturing method, applied in non-rotational vibration suppression, devices for applying liquid to surfaces, interconnection systems, etc. Excellent mass productivity, simple manufacturing quality, effect of achieving target adhesion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, in order to clarify the present invention more specifically, embodiments of the present invention will be described in detail with reference to the drawings.

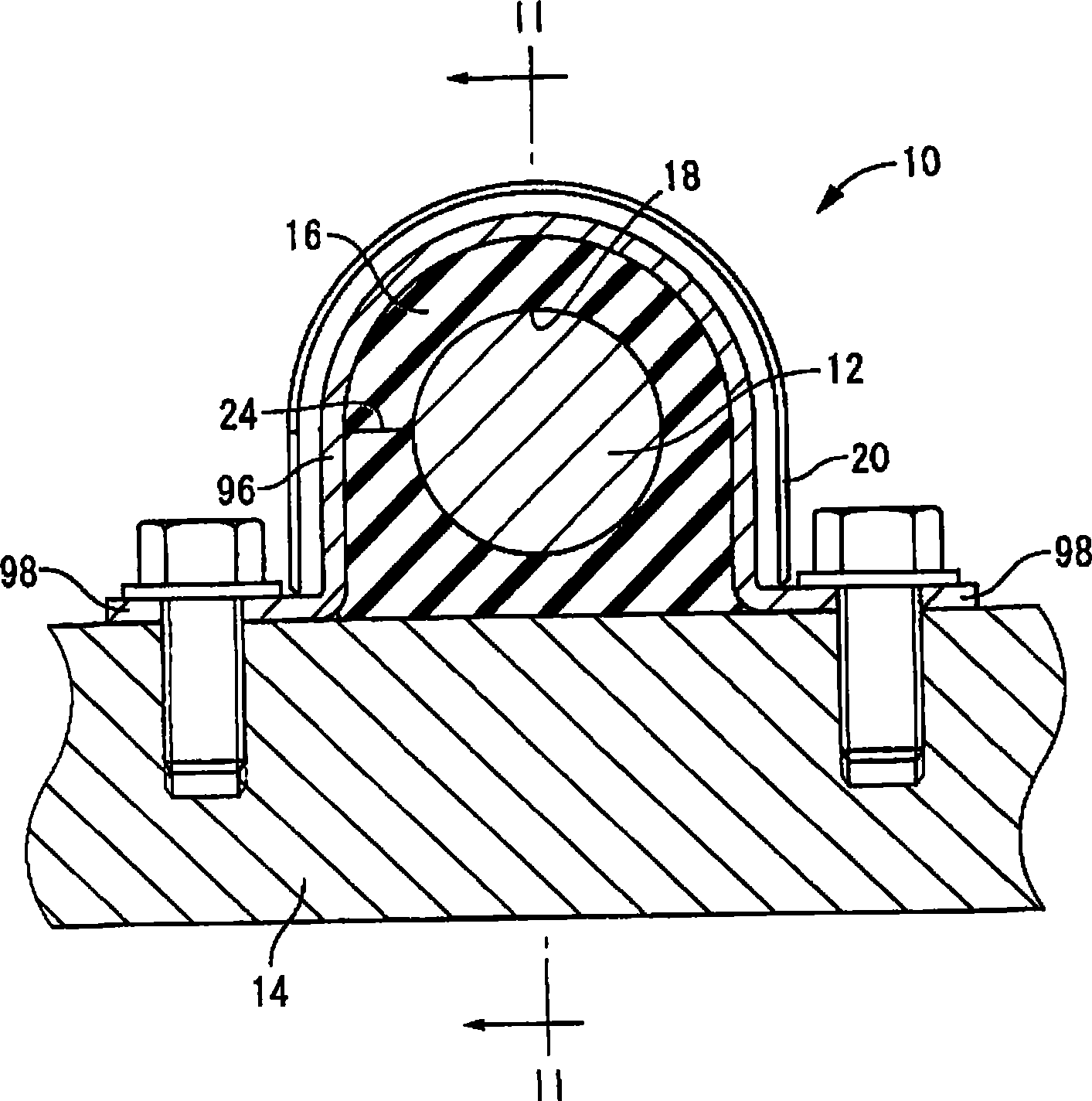

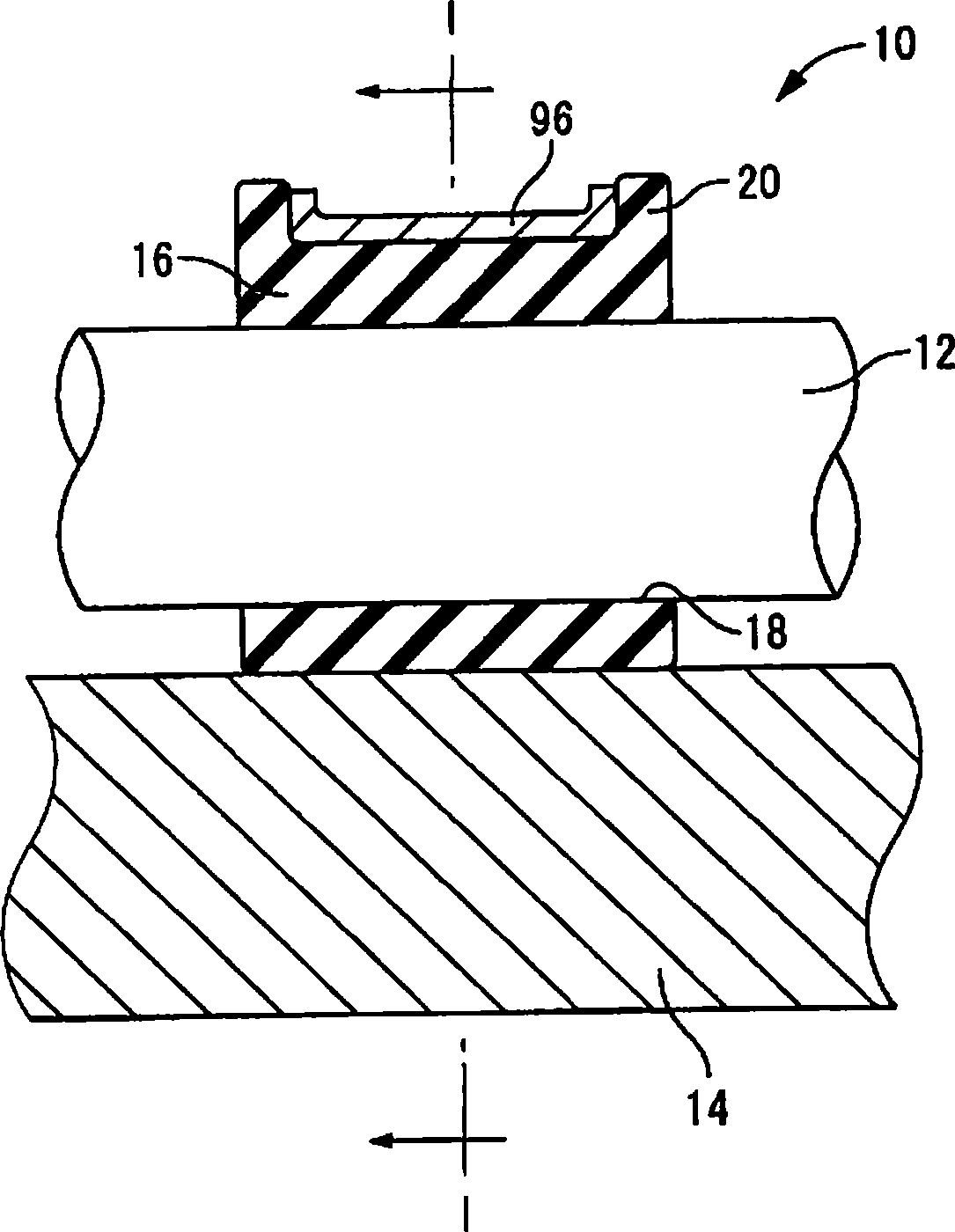

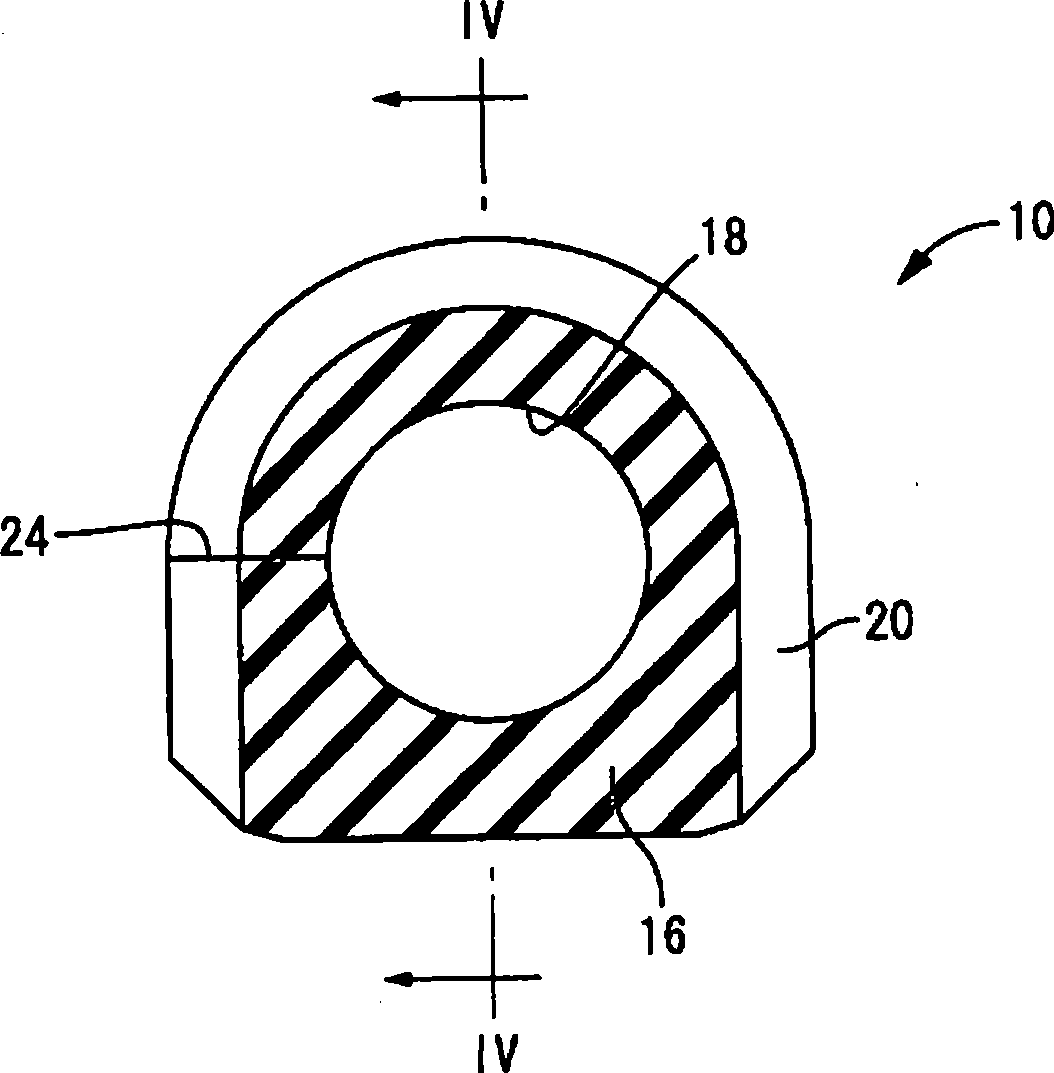

[0056] first, figure 1 , 2 It is an example of a lubricant-carrying rubber bush having a structure according to the present invention, and shows a state in which a stabilizer bush 10 for an automobile is mounted on a vehicle. The stabilizer bush 10 has a cylindrical shape as a whole, and is fitted over the stabilizer bar 12 as a member elastically connected, that is, a rod-shaped member. The inner peripheral surface of the stabilizer bush 10 can slide relative to the outer peripheral surface of the stabilizer bar 12. The outer peripheral surface of the stabilizer bar 12 overlaps with the outer peripheral surface of the stabilizer bush 12, and the vehicle body 14, which is another member elastically connected, is fixedly attached to the outer peripheral surface of the stabilizer bush 10. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com