Drying apparatus of granule type preparation

A granular and preparation technology, which is applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of not being able to improve the appearance and density of disposal objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

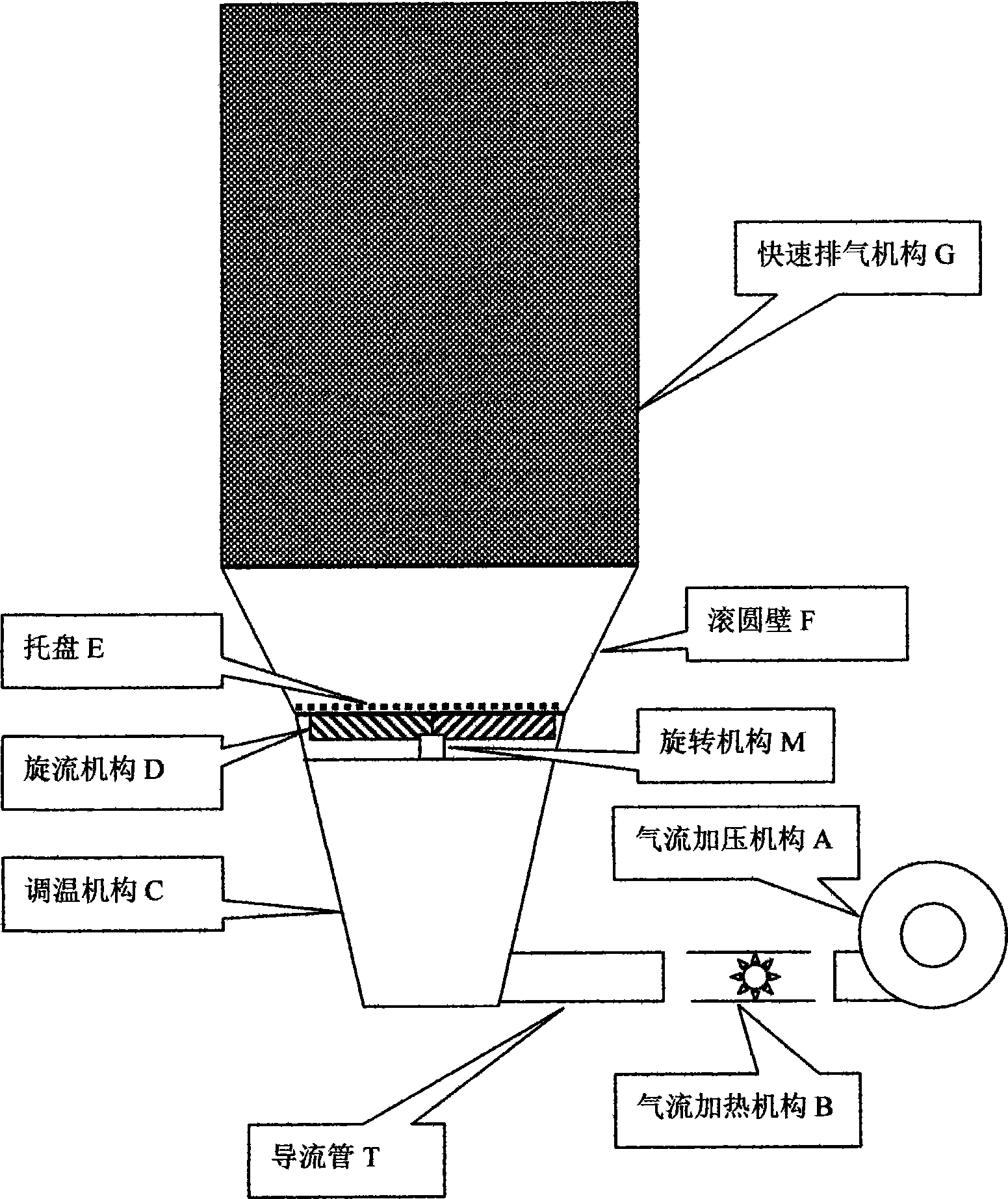

[0017] Embodiment Example 1. Drying of starch blank granules

[0018] Add 20 kilograms of 20-80 mesh starch blank granules that have been granulated into the present invention.

[0019] Disposals are placed on the disposal tray E.

[0020] A 1500W medium pressure fan is used to blow air into the equipment.

[0021] Heat the airflow to 40 °C with a 4 kW electric airflow heating mechanism B.

[0022] The ventilation holes in the swirl mechanism D form an included angle of 40 degrees with the horizontal direction.

[0023] Adjust the rotation speed of the rotating mechanism M to 60r / min, which is consistent with the direction of the vent hole.

[0024] The fast exhaust mechanism G selects a single-layer material with a pore size of 100 mesh.

[0025] Under the temperature of 30 degrees Celsius and relative humidity of 70%, the disposal can be dried to a water content of less than 7% in 35 minutes, and the particles are approximately spherical.

[0026] Embodiment example two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com