Bullet shock testing method of coating layer-substrate interface binding performance

A technology of interface bonding and impact testing, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of inability to evaluate the bonding performance of the strongly bonded coating layer and the substrate interface, high production requirements, and low load level, etc., to achieve a clear model , strong operability and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

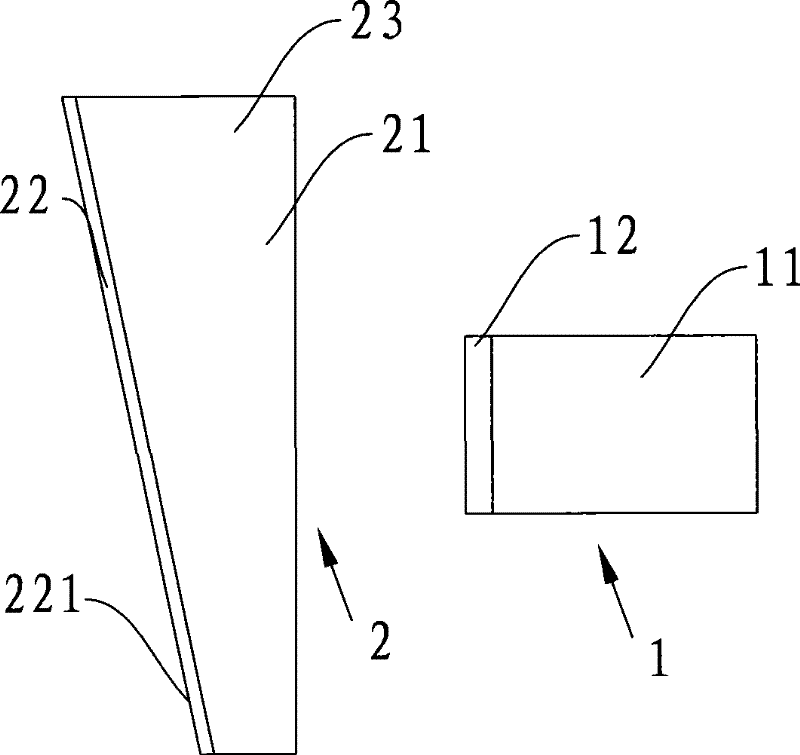

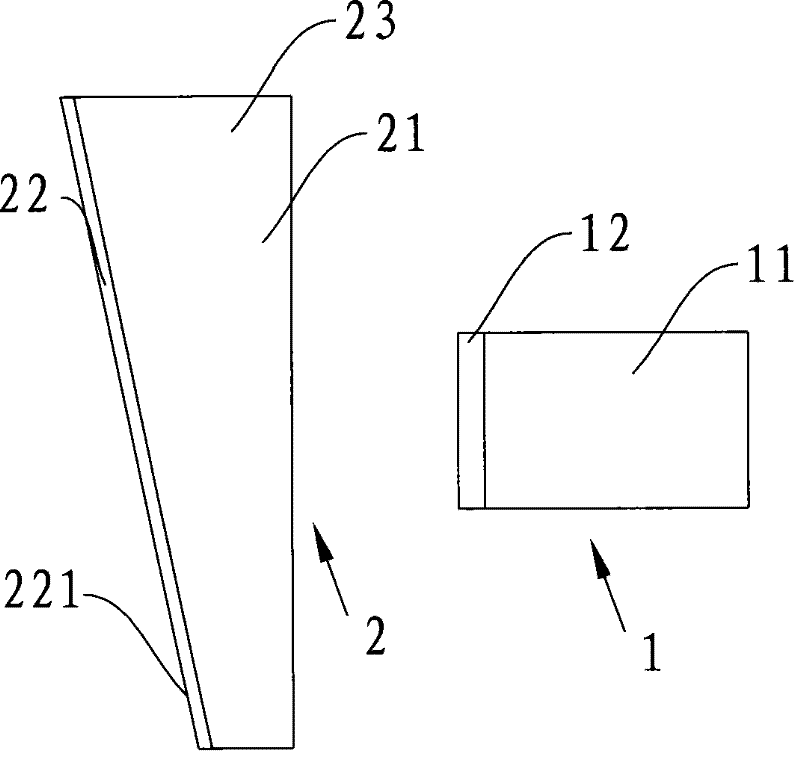

[0021] see figure 1 and figure 2 , the projectile impact method based on the spallation effect that the present invention proposes, basic principle is to use the lower material (such as plastics) of acoustic impedance as cylindrical projectile 1, by cylindrical projectile substrate 11 and plated on the front end face of projectile substrate 11 The shot coating 12 is composed of the shot coating 12, and the acoustic impedance of the shot coating 12 is close to that of the sample matrix 21.

[0022]

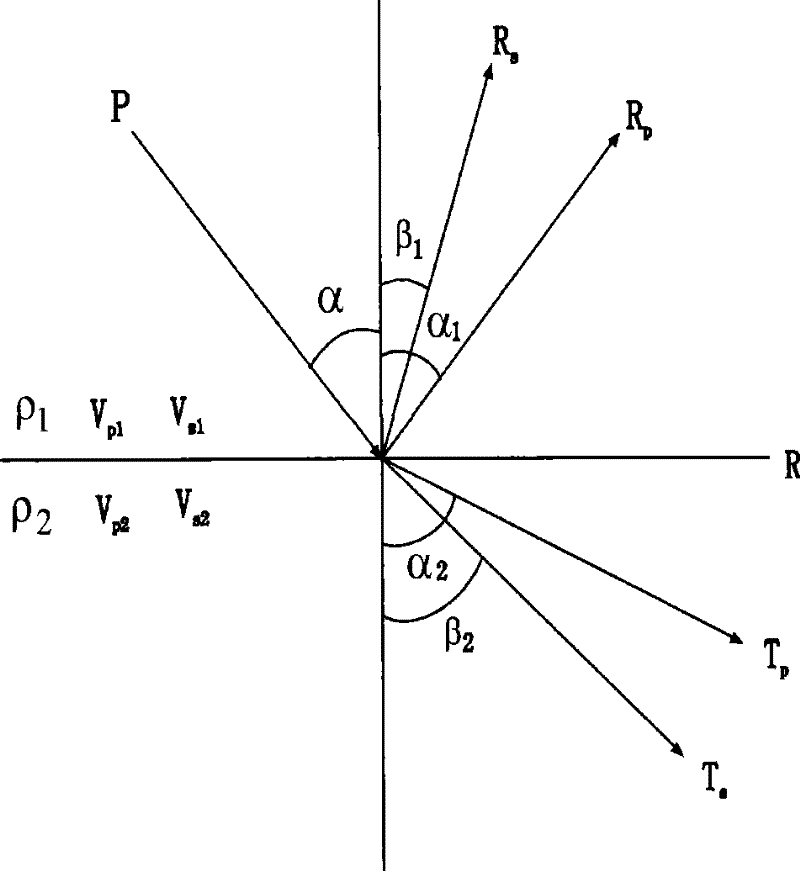

[0023] Sample 2 is fixed on the bracket, the surface of the substrate coated with coating on sample 2 forms an angle α with the horizontal plane, and the projectile 1 is launched by a projectile launching device, such as an air gun, ballistic gun or gas cannon, so that the projectile 1 moves along the vertical direction of the sample. direction at a certain velocity V 0 The free surface 21 of the substrate of the sample 2 is impacted, and a compressive stress wave P is genera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap