Bus connector

A busbar connector, grounding wire technology, applied in the direction of connection, clamping/spring connection, protective grounding/shielding device of connecting parts, etc. To reliable guarantee, the size of the cabinet becomes larger, etc., to achieve the effect of miniaturization of cabinet design, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with a preferred embodiment and accompanying drawings.

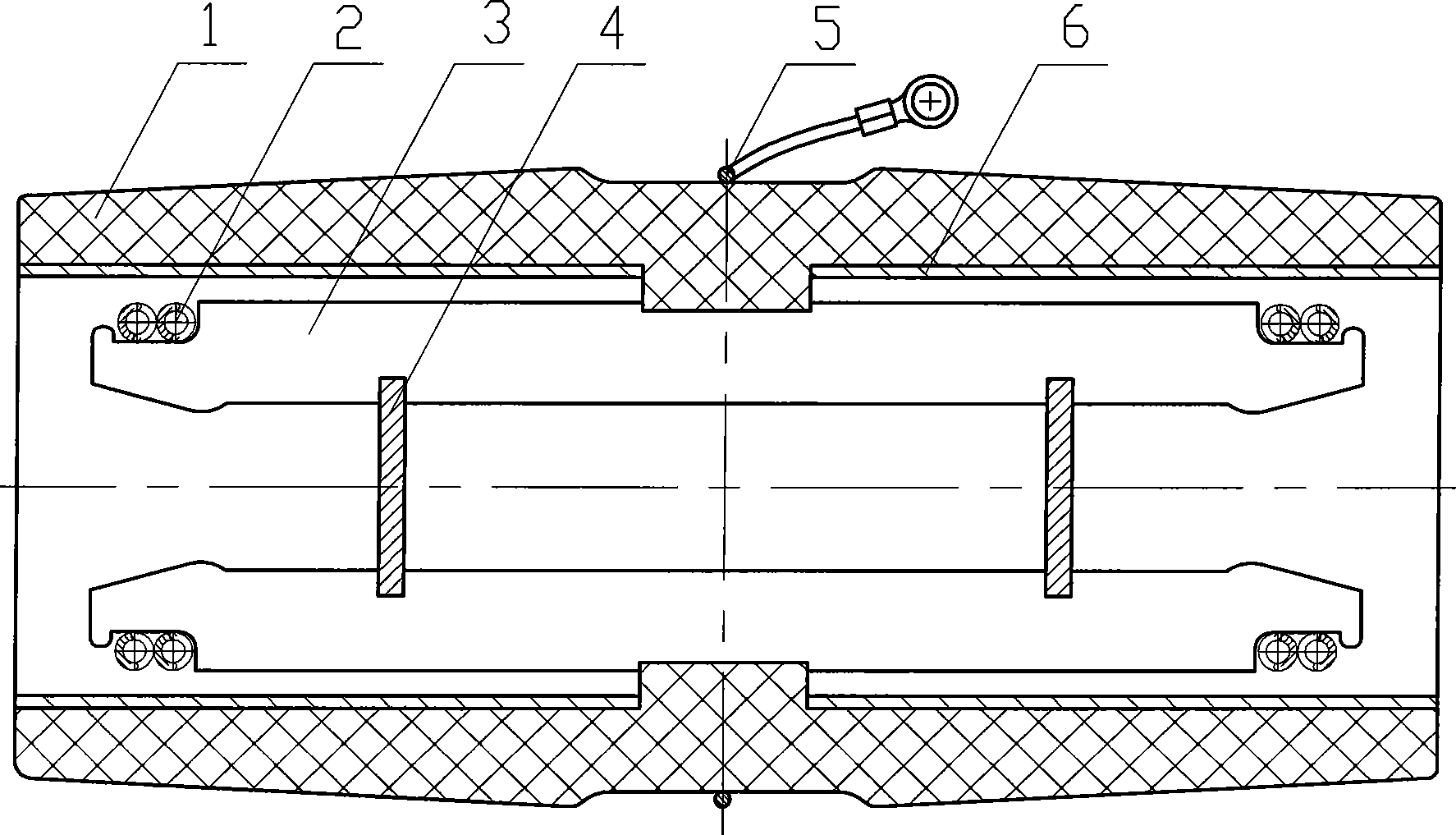

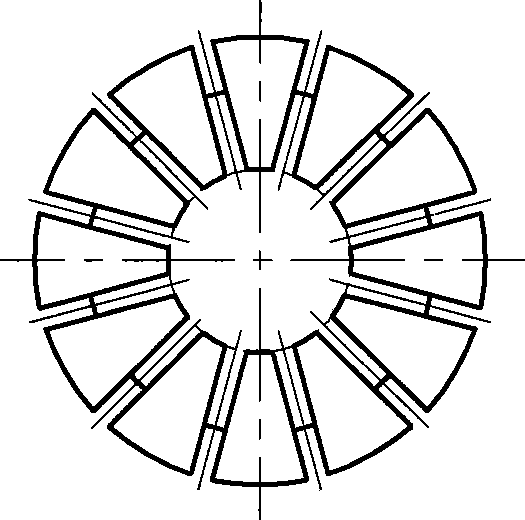

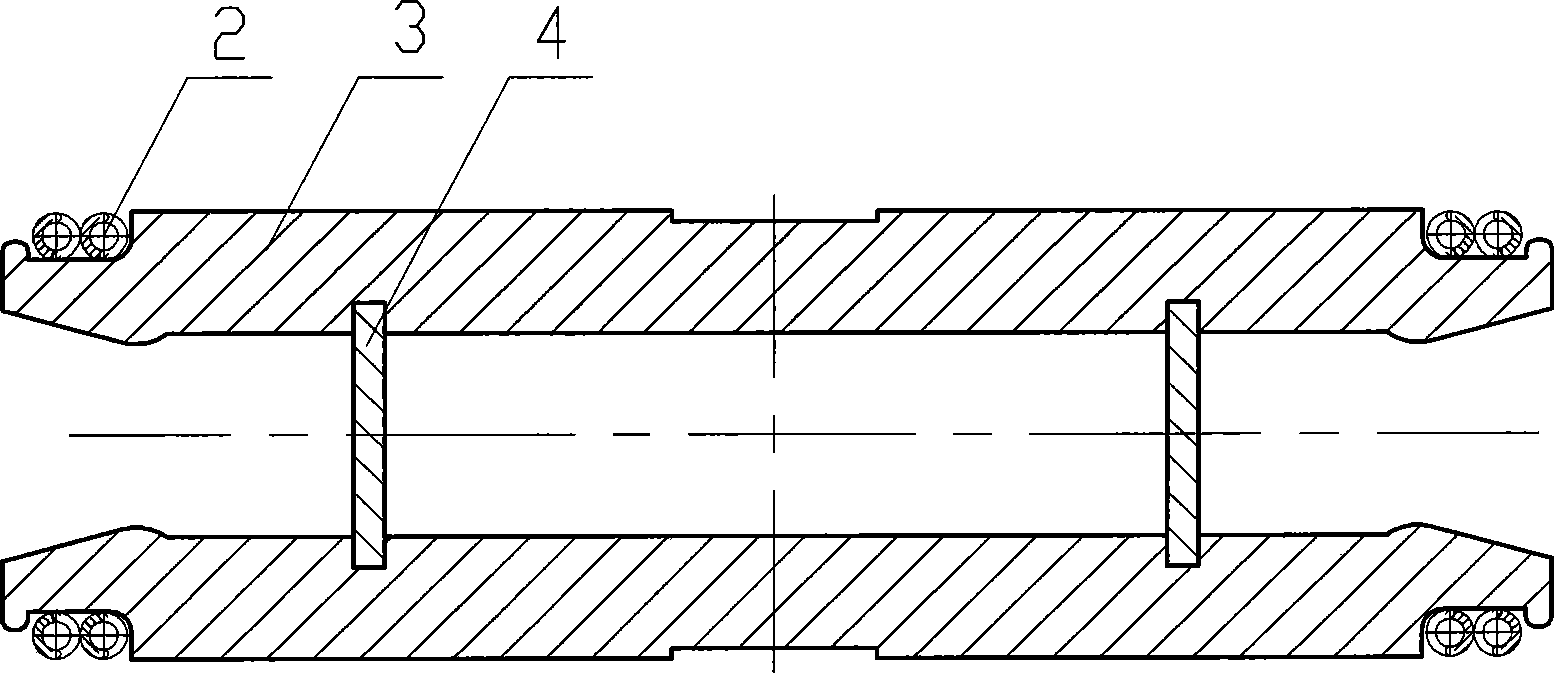

[0010] as attached figure 1 , attached Figure 2A , 2B As shown, this embodiment is mainly composed of a rubber sleeve 1, a spring 2, a fan-shaped contact piece 3, a grid piece 4, a ground wire group 5, and an aluminum tube 6. The fan-shaped contact piece 3 is installed in the slot of the grid piece 4, and then They are fixed together by a spring 2 to form a fan-shaped contact 7 . Install aluminum tubes 6 at both ends of the inner cavity of the rubber sheath 1, then insert sector contacts 7, and then install a ground wire group 5 in the middle of its outer surface to form a busbar connector. After the above-mentioned structure is adopted in the present invention, the busbar connector has a strong flow capacity, can meet the requirements of a switchgear with a rated current of 1250A when combining cabinets, and has a design use margin of 1.2 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com