Flame proof cable winding drum

An explosion-proof cable reel and reel technology, which is applied to circuits, current collectors, electrical components and other directions, can solve the problems such as the aging and looseness of the electric brush clamping device, the easy wear of the electric brush, and the burning out of the slip ring, etc. The effect of ensuring the contact area and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

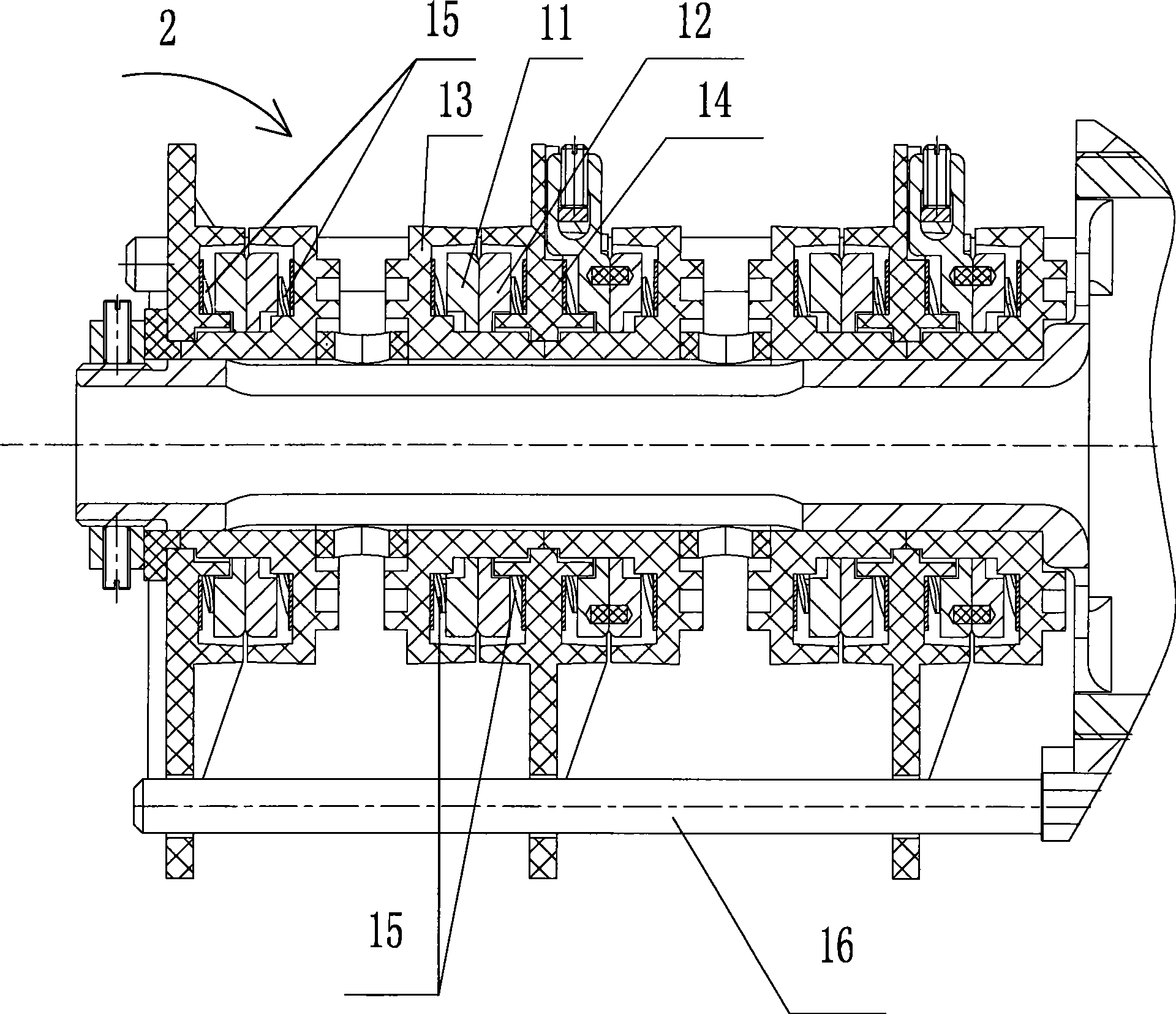

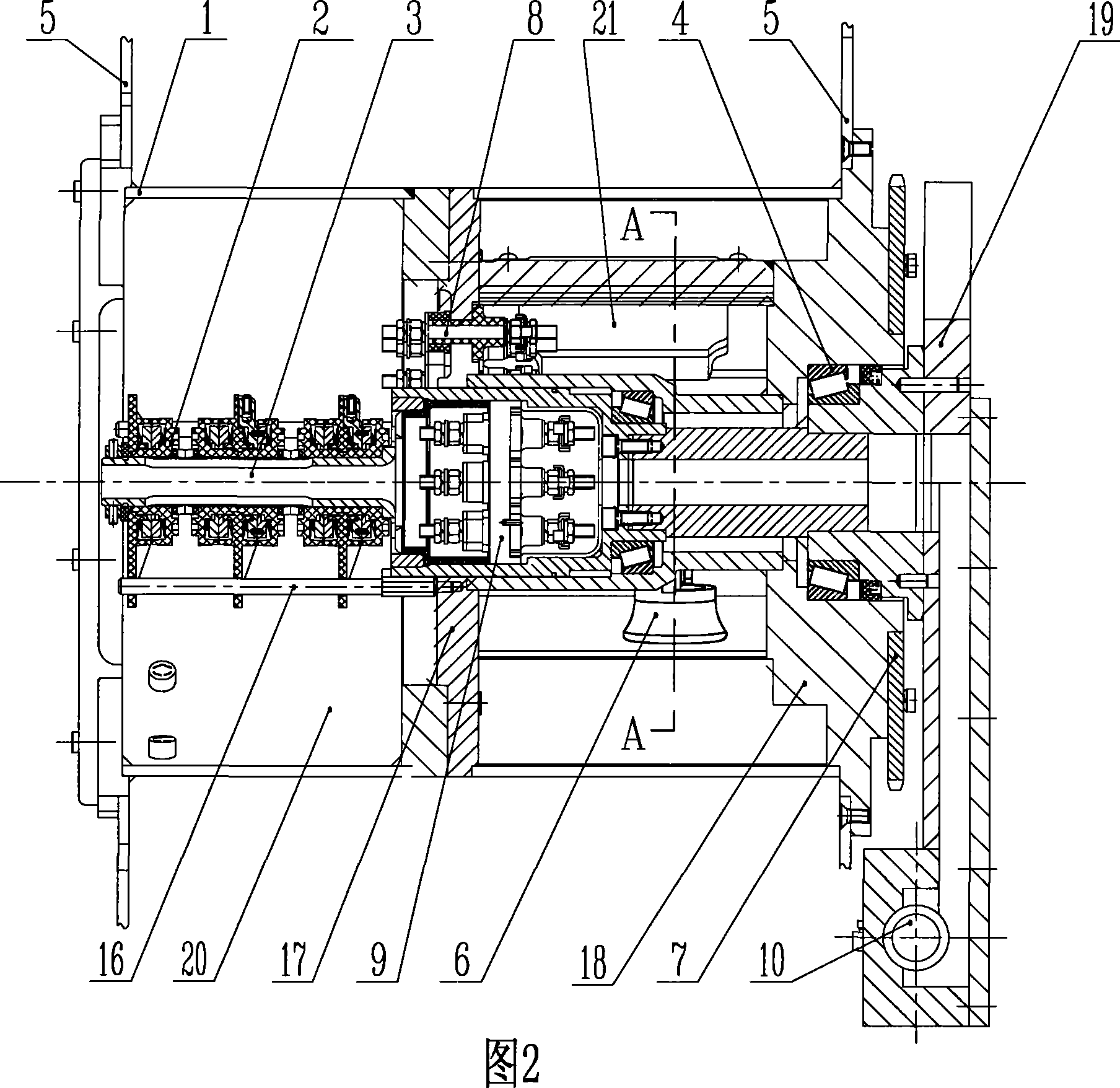

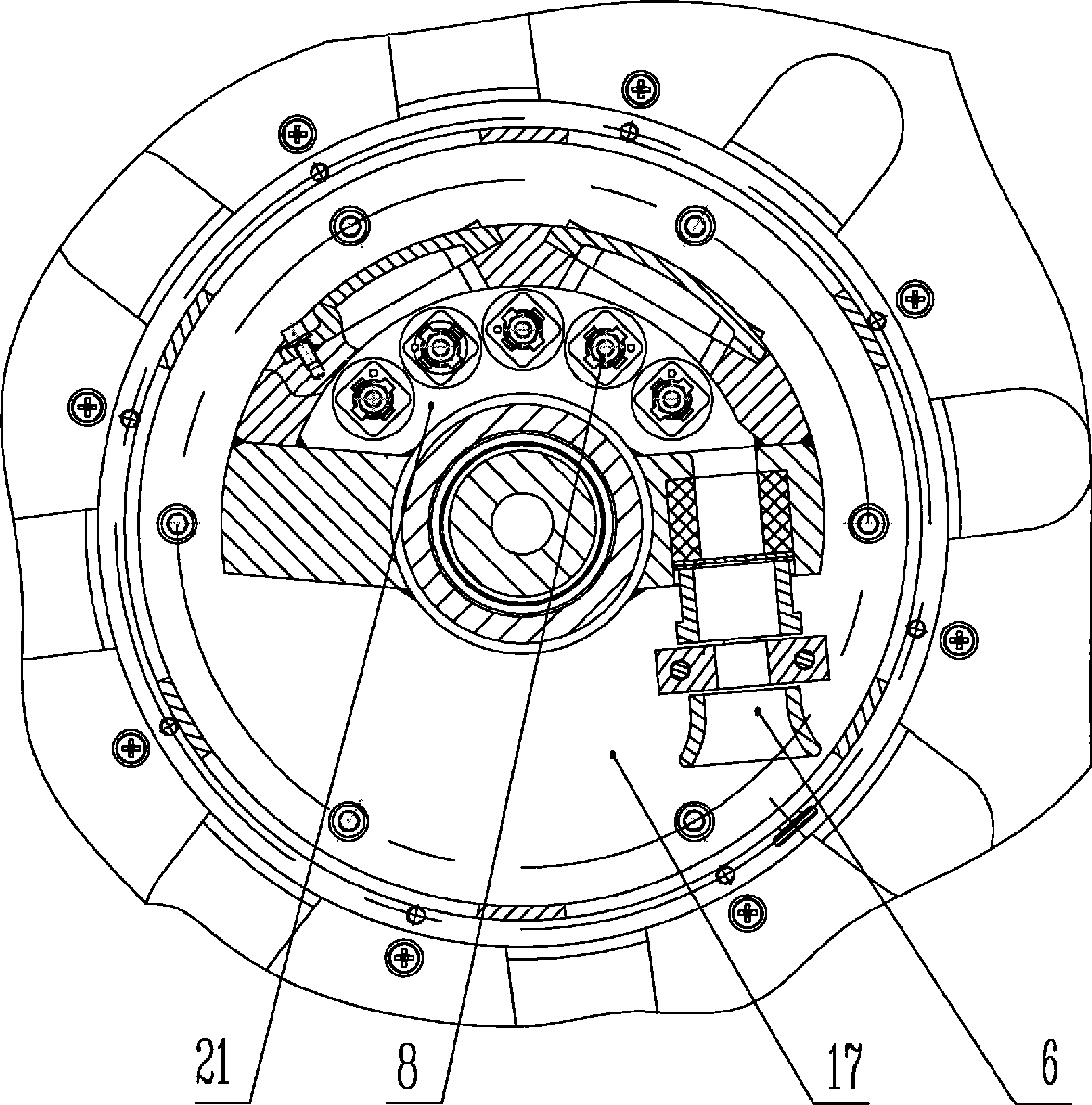

[0017] Such as Figure 1-Figure 3 As shown, the collector slip ring 2 of the present invention is provided with two slip rings, one is a static slip ring 11, and the other is a dynamic slip ring 12, and the static slip ring 11 is in contact with the end surface of the dynamic slip ring 12; the static slip ring 11 passes through The static slip ring seat 13 is fixed on the hollow shaft 3 and is relatively stationary; the moving slip ring 12 is set on the hollow shaft 3 through the moving slip ring seat 14, and the outer edge of the moving slip ring seat 14 is provided with a The cantilever shaft 16 on the middle flange 17, three cantilever shafts 16 are evenly distributed, so that the movable slip ring 12 is driven by the drum shell 1 to rotate relative to the hollow shaft 3, and the rotational angular speed is the same as that of the drum shell 1 , can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com