Ball bearing cage

A technology for ball bearings and races, applied in the direction of ball bearings, bearing elements, shafts and bearings, etc., can solve problems such as excessive wear of races, degradation of bearing lubrication, etc., to reduce wear of races and balls, reduce deformation, and lighten The effect of the axial part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

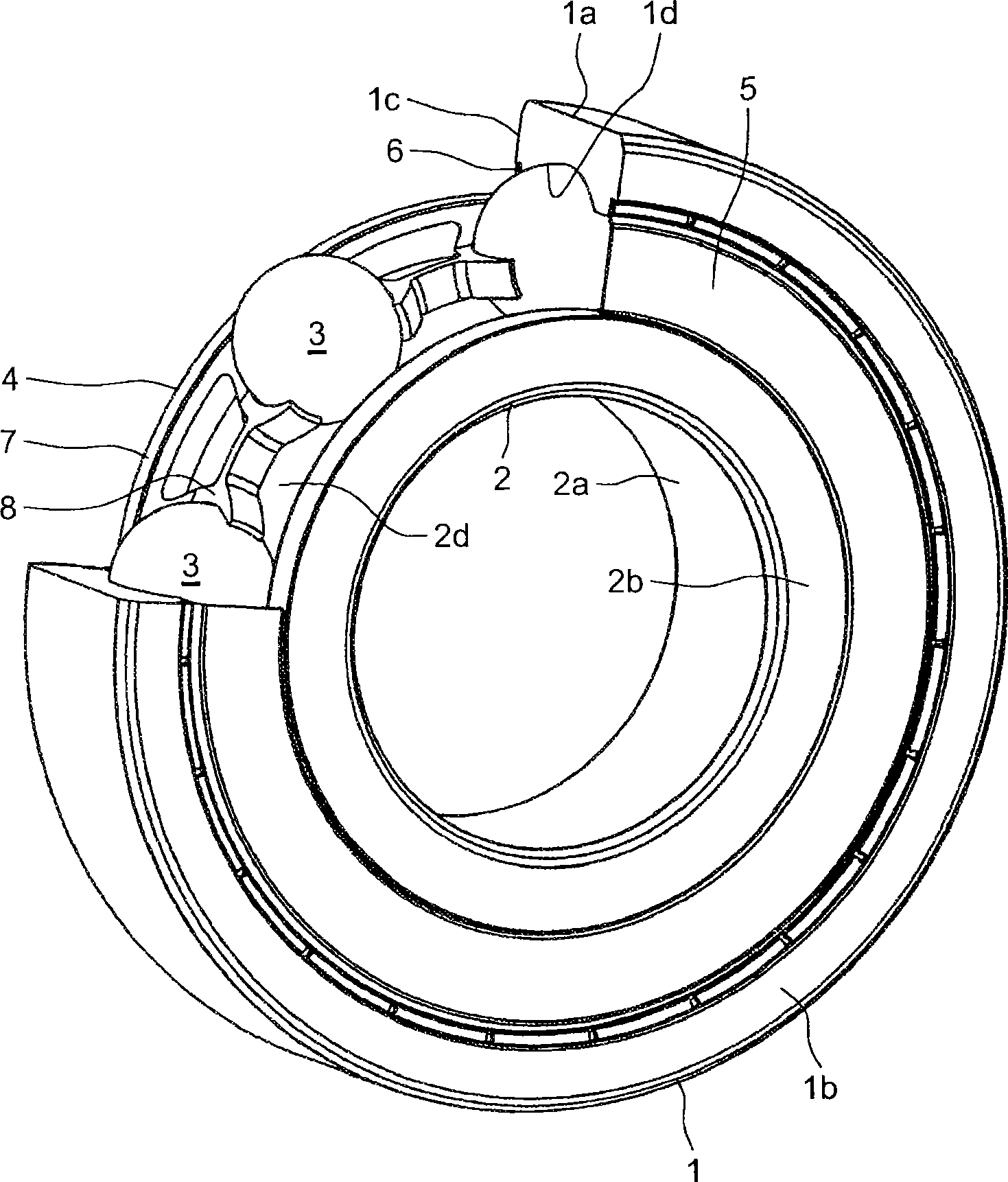

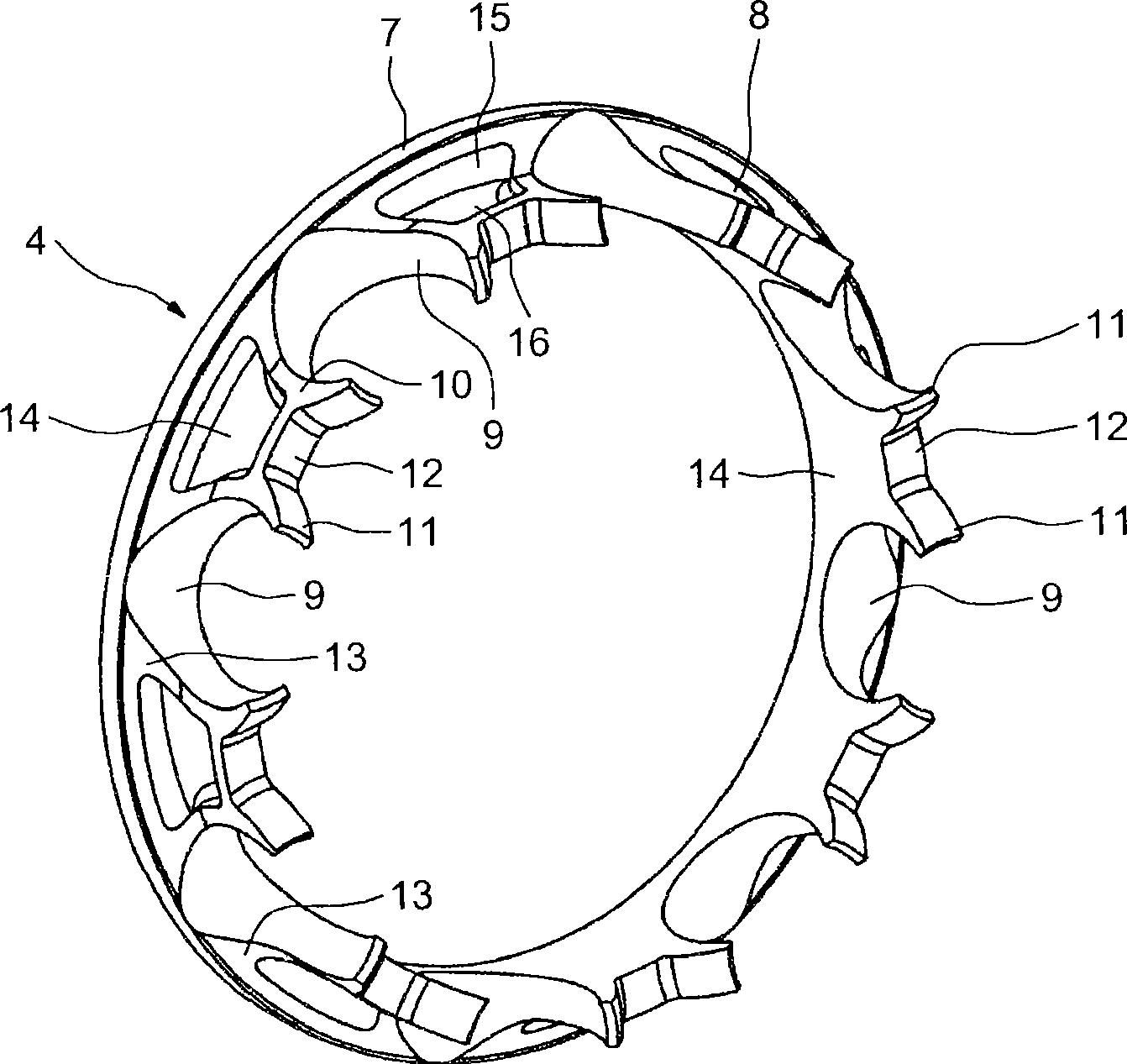

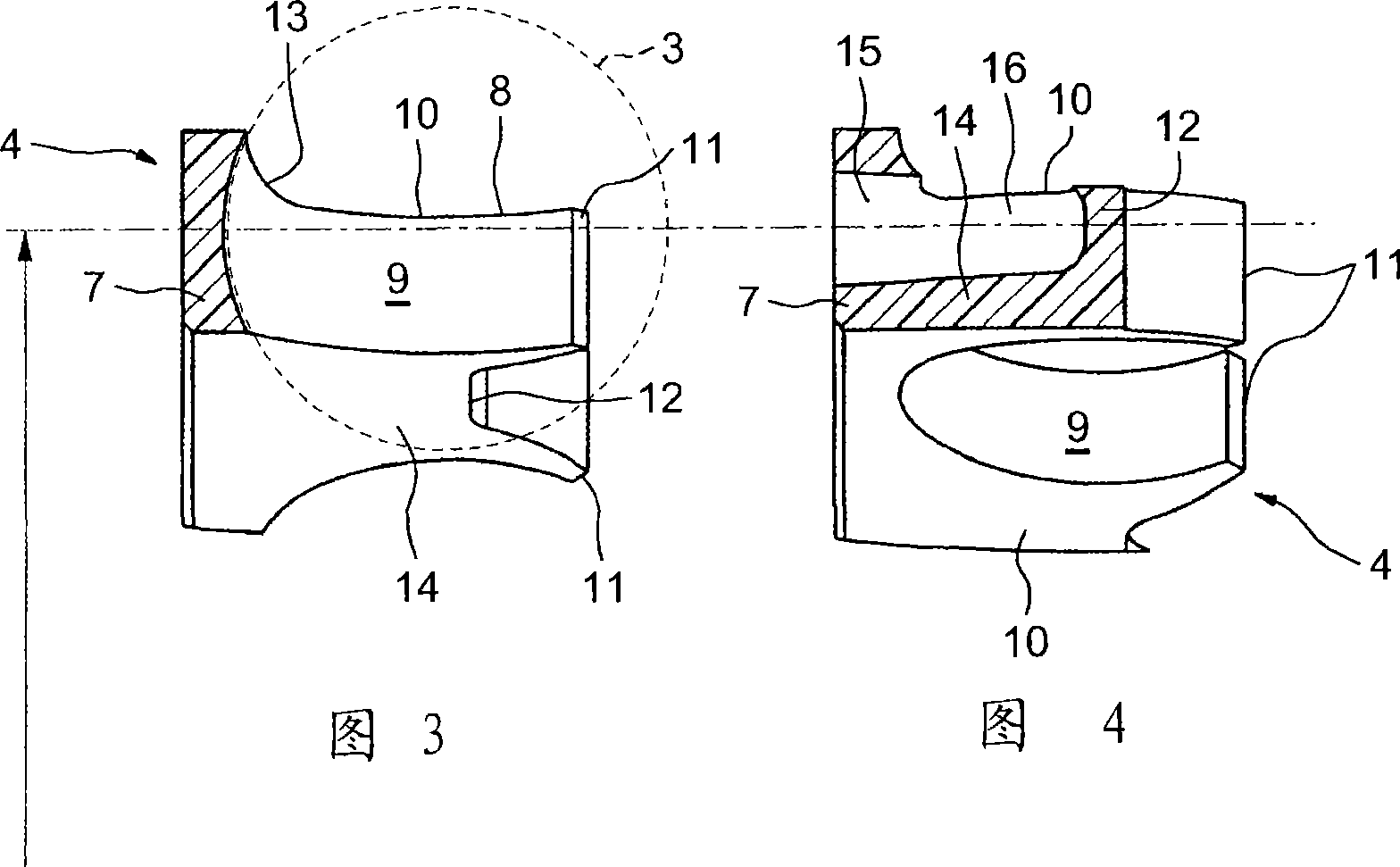

[0034] from figure 1 As can be seen in , the rolling bearing assembly includes an outer ring 1; an inner ring 2; a row of rolling elements 3, in this case balls; a race 4 for maintaining the circumferential spacing of the rolling elements 3; and sealing plates 5 and 6.

[0035] The outer ring 1 and the inner ring 2 are deep grooved, for example formed by machining a part of a pipe. The outer ring 1 comprises a cylindrical axially outer surface 1 a ; opposite radial front surfaces 1 b and 1 c ; and a bore forming a raceway 1 d for the rolling elements 3 . The inner ring 2 comprises a cylindrical bore 2 a ; two opposite radial front surfaces 2 b and 2 c ; and an outer surface forming a track 2 d for the rolling elements 3 . The outer ring 1 is equipped with two symmetrical sealing grooves into which sealing plates 5 and 6 fit respectively from the same side as the radial surface 1 b and the same side as the radial surface 1 c. The sealing plates 5 and 6 form narrow passages, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com