Load unit for compression bearing test of angle iron component

A technology of loading device and bearing capacity, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems such as the inability to realize the compression of angle steel and simulate various end constraints, and achieve clear force transmission, easy installation and disassembly of components, and application of Load accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

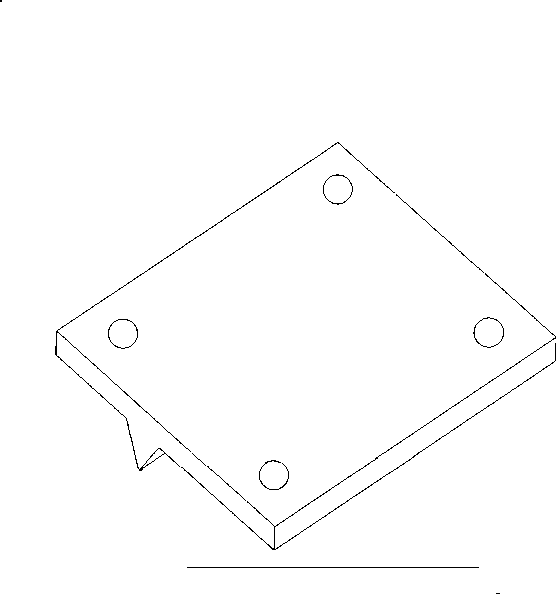

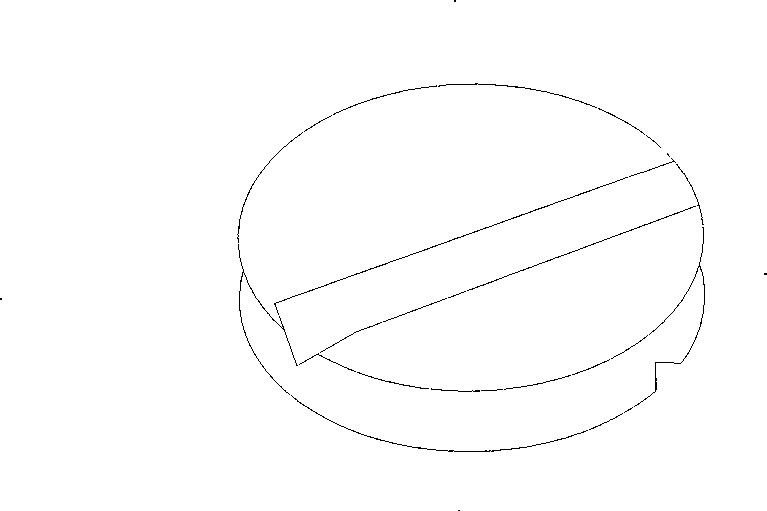

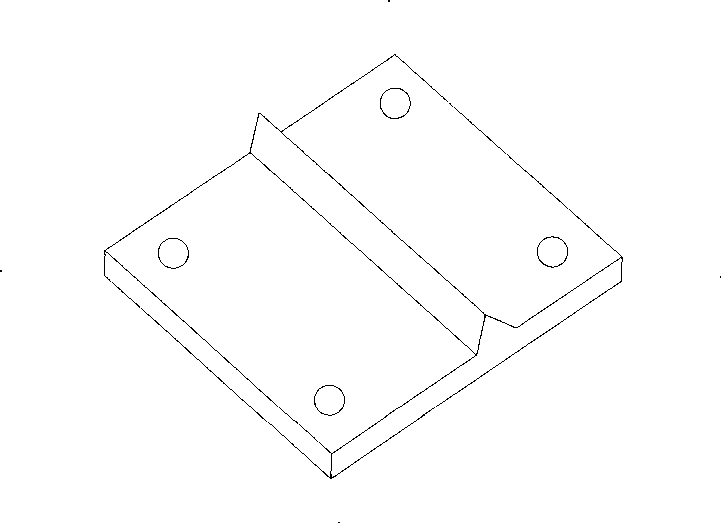

[0024] in figure 2 The embodiment is a schematic diagram of simulating a situation where an angle steel member is loaded under compression. figure 2 The hydraulic press, sensor, ball head and ball head seat shown are on the same plumb line, Figure 5 It is the structural drawing of the bottom ball seat. Install the two ends of the angle steel member to be tested to Figure 3 and Figure 4 The top clamp and bottom clamp are shown.

[0025] The specific description in combination with the reference numerals has been described in detail in the content of the invention, and will not be repeated here. When installing, rotate the top screw rod and the bottom screw rod to make the top pressure block and the bottom pressure block press and fix the two ends of the angle steel. The axial compression and eccentric compression of the angle steel member are realized by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com