Process control method and device thereof

A process control and process technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of complex control process, low feasibility, complex calculation process, etc., to avoid process drift and reduce Calculation amount, the effect of reducing the amount of calculation

Active Publication Date: 2010-11-24

BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The exponential weighted moving average method is only suitable for single-input-single-output control systems. When performing multi-input single-output and multi-input multi-output system control, the calculation process is very complicated. If a small link in the control model is not handled properly, it may leading to high errors;

For nonlinear programming control methods, the difficulty lies in the complexity and uncertainty of the calculation process (not all nonlinear programming problems can be solved);

Model predictive control method, because the control process involved is too complicated, the feasibility of its application in actual process production is not very great

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

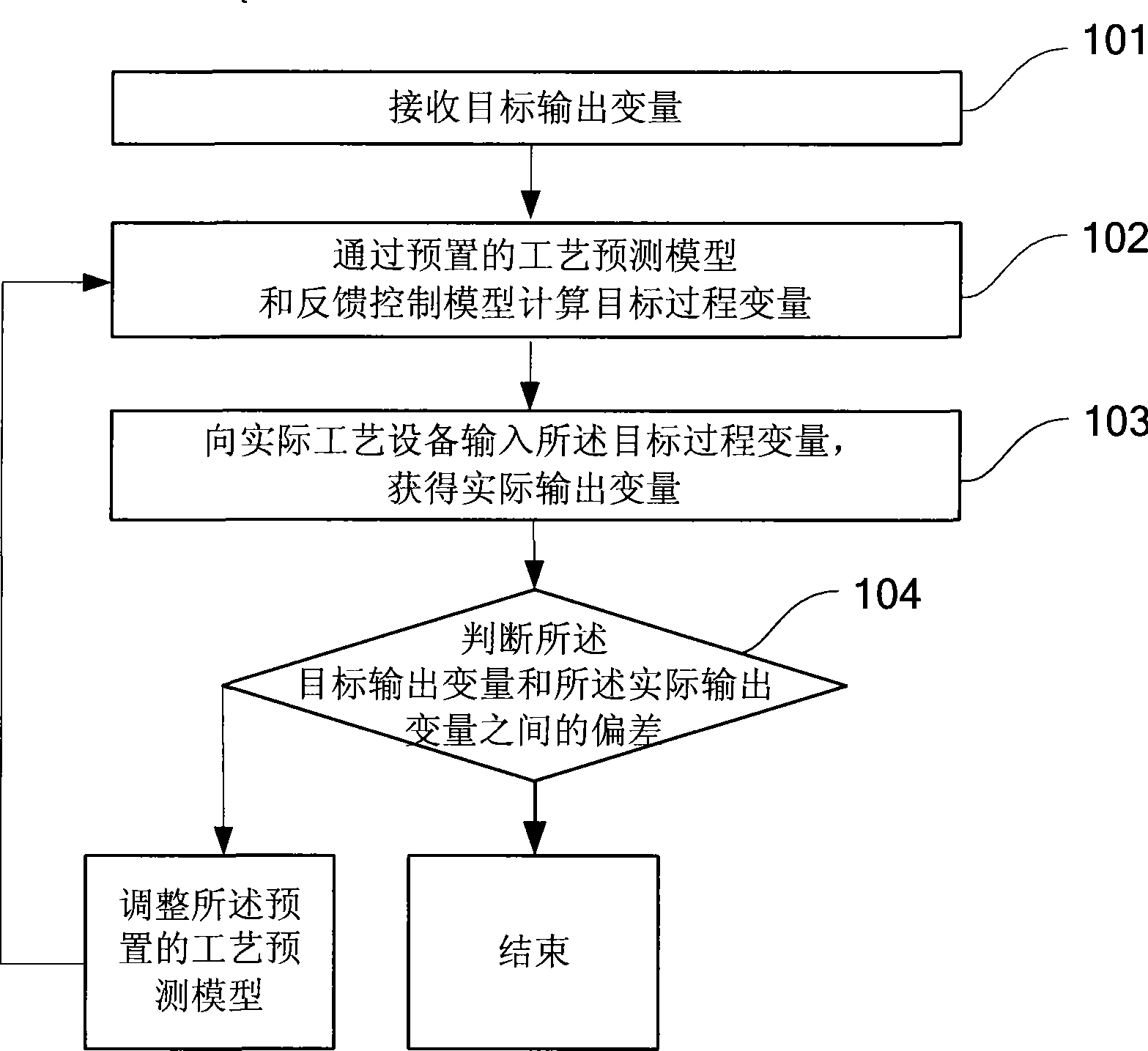

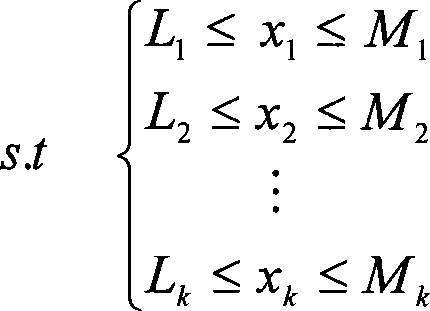

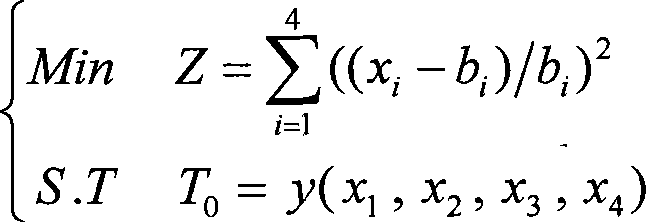

The invention provides a process control method which comprises the following steps: step a, receiving a target output variable; step b: computing a target procedure variable by a preset process prediction model and a feedback control model, wherein, the process prediction model is used for describing a functional relation between the procedure variable and the output variable, a target function of the feedback control model is used for solving the target procedure variable which has the minimum distance from a preset reference value, and a constraint condition of the feedback control model is that the target output variable and the target procedure variable correspond with the process prediction model; step c, inputting the target procedure variable to actual process equipment to obtain an actual output variable; and step d, judging the deviation between the target output variable and the actual output variable, adjusting the preset process prediction model and repeating the step b if the deviation does not meet a preset requirement, or ending the step if the deviation meets the preset requirement. The process control method has relatively obvious effect on reducing the computational complexity and improving the control precision.

Description

A process control method and device technical field The invention relates to the technical field of industrial process control, in particular to a process control method and device. Background technique Process feedback control, that is, control using feedback information. The actual working performance of the production system is measured by the sensing system or measuring system, and then compared with the required standard. If there is a difference, it will be explained by the control system, and the control system will give commands to the operating device in order to correct the work performance. Eliminate variance. This is the simplest feedback-based model. For example, in the semiconductor etching process, the feedback control technology of the process is a very critical technology. In recent years, with the continuous update of process etching technology, people have higher and higher requirements for etching equipment and silicon wafer quality control during t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B13/02

CPCG05B13/048

Inventor 张善贵

Owner BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com