Test modal analysis method based on reduced-basis method

A technology of test mode and analysis method, which is used in the testing of machine/structural components, vibration testing, measuring devices, etc., and can solve the problems of low iterative convergence speed, large amount of calculation, and low convergence speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

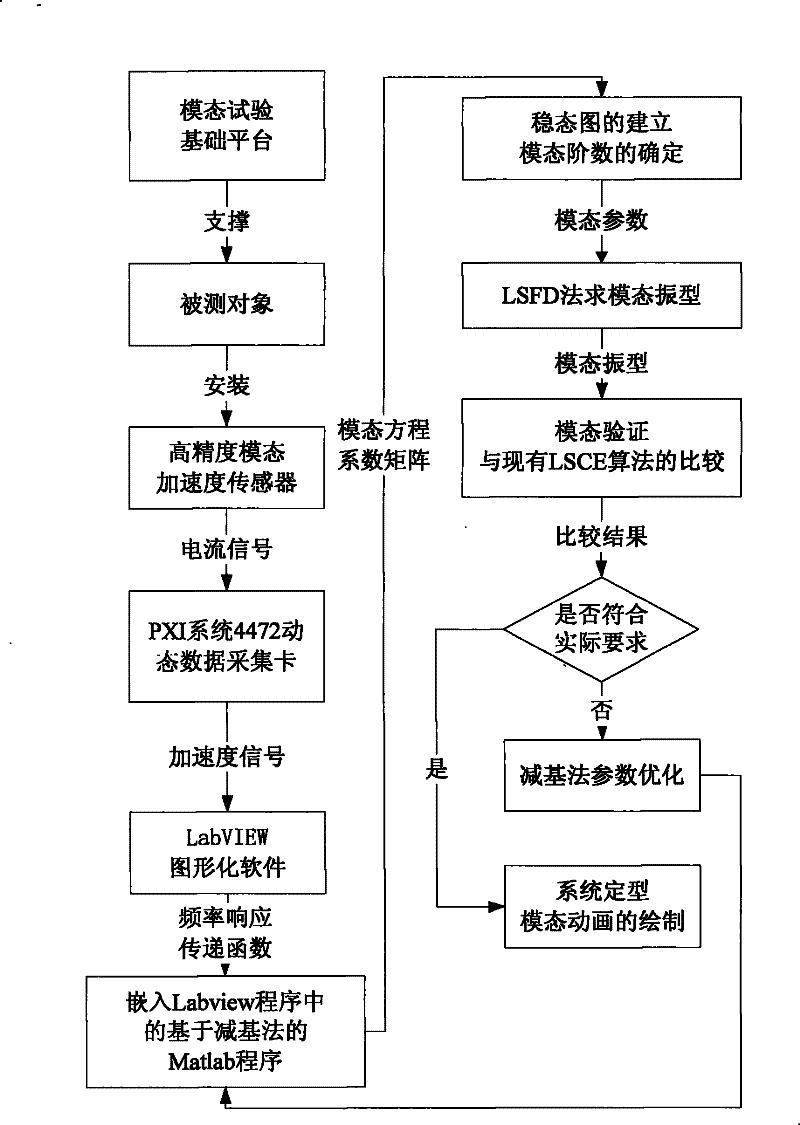

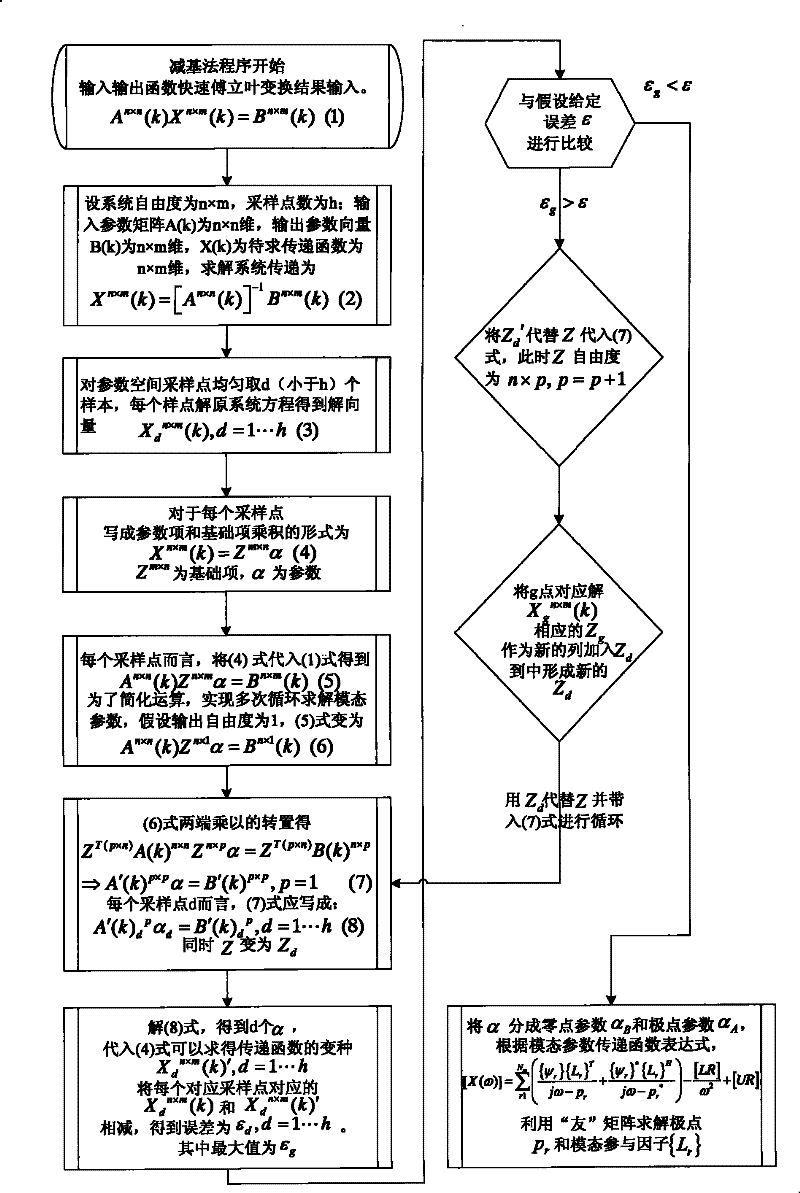

[0033] Such as figure 1 and figure 2 Shown, the present invention discloses a kind of test modal analysis method based on subtraction method, and its steps are:

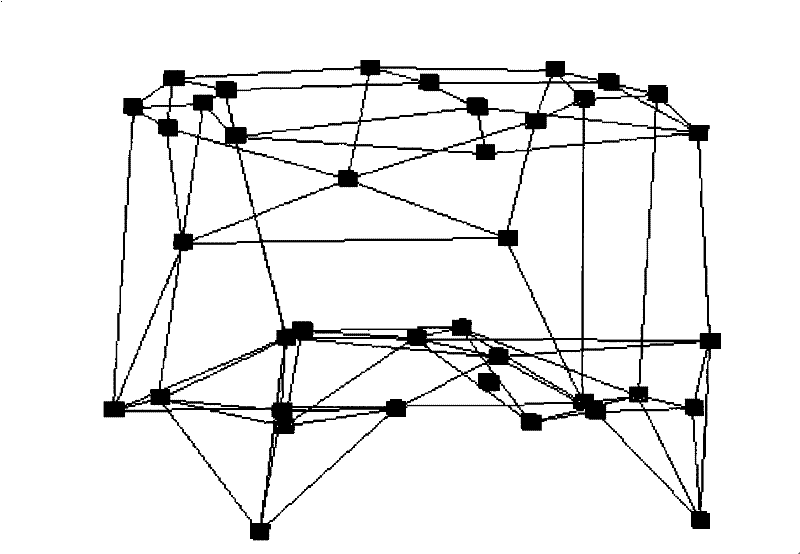

[0034] (1) The preparation process of the test modal analysis, including checking whether the measured object meets the necessary conditions of the test, namely linear time invariance, observability and Maxwell reciprocity principle, installation of the test platform, hoisting of the test product, test The drawing of the geometric dimensions of the product, the determination of the test method include the use of the exciter vibration method or the hammer method (we use the hammer method here), the selection of the sensor layout, the installation and initialization of the sensor, etc.

[0035] (2), dynamic acceleration signal acquisition, and use LabVIEW graphical software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com