Magneto-resistive effect device of the cpp type, and magnetic disk system

A magneto-resistance effect element and magneto-resistance effect technology, applied to electrical components, measuring devices, and resistors controlled by a magnetic field, can solve problems such as characteristic changes, unstable pinning functions, and insufficient pinning functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

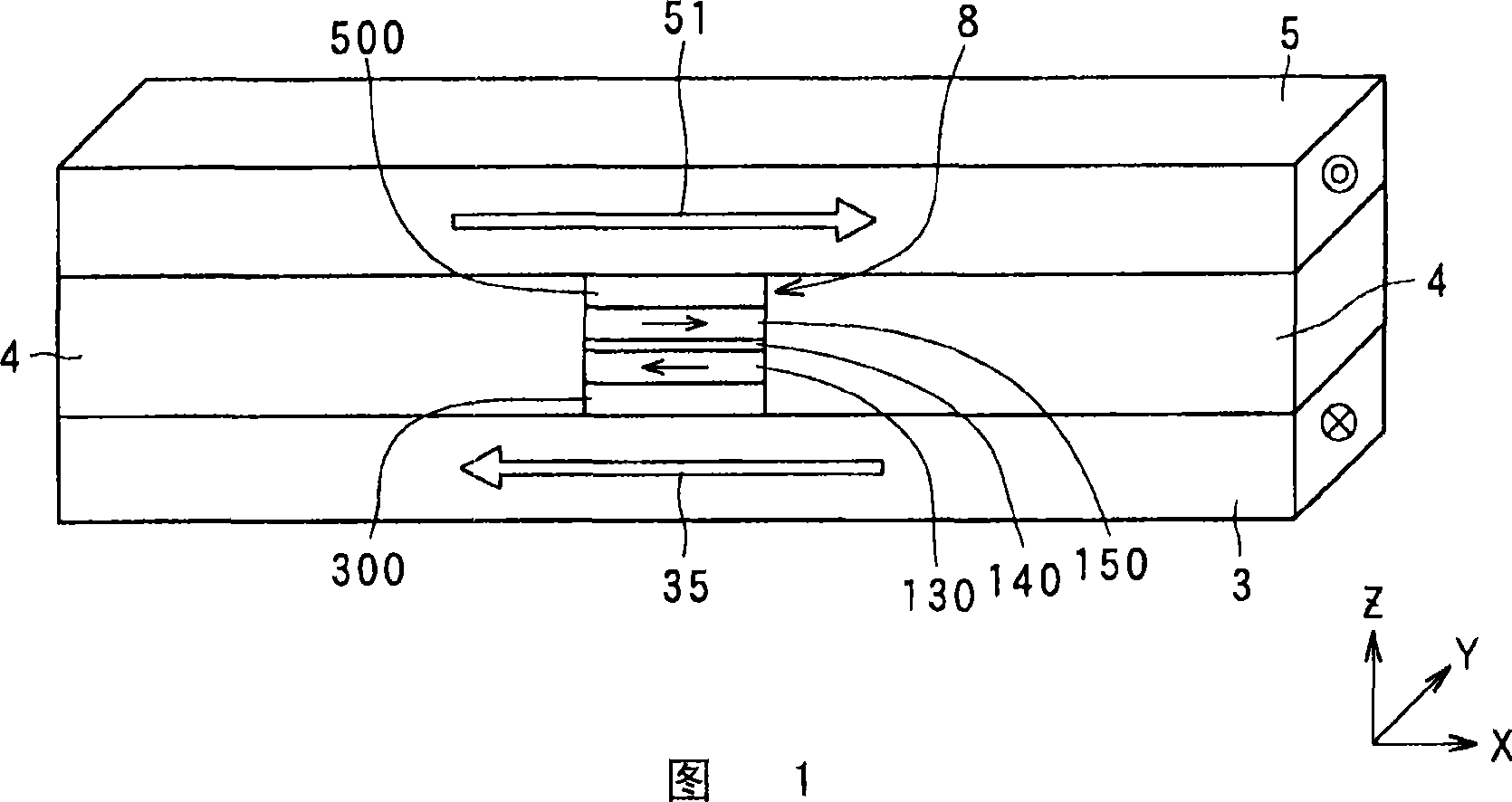

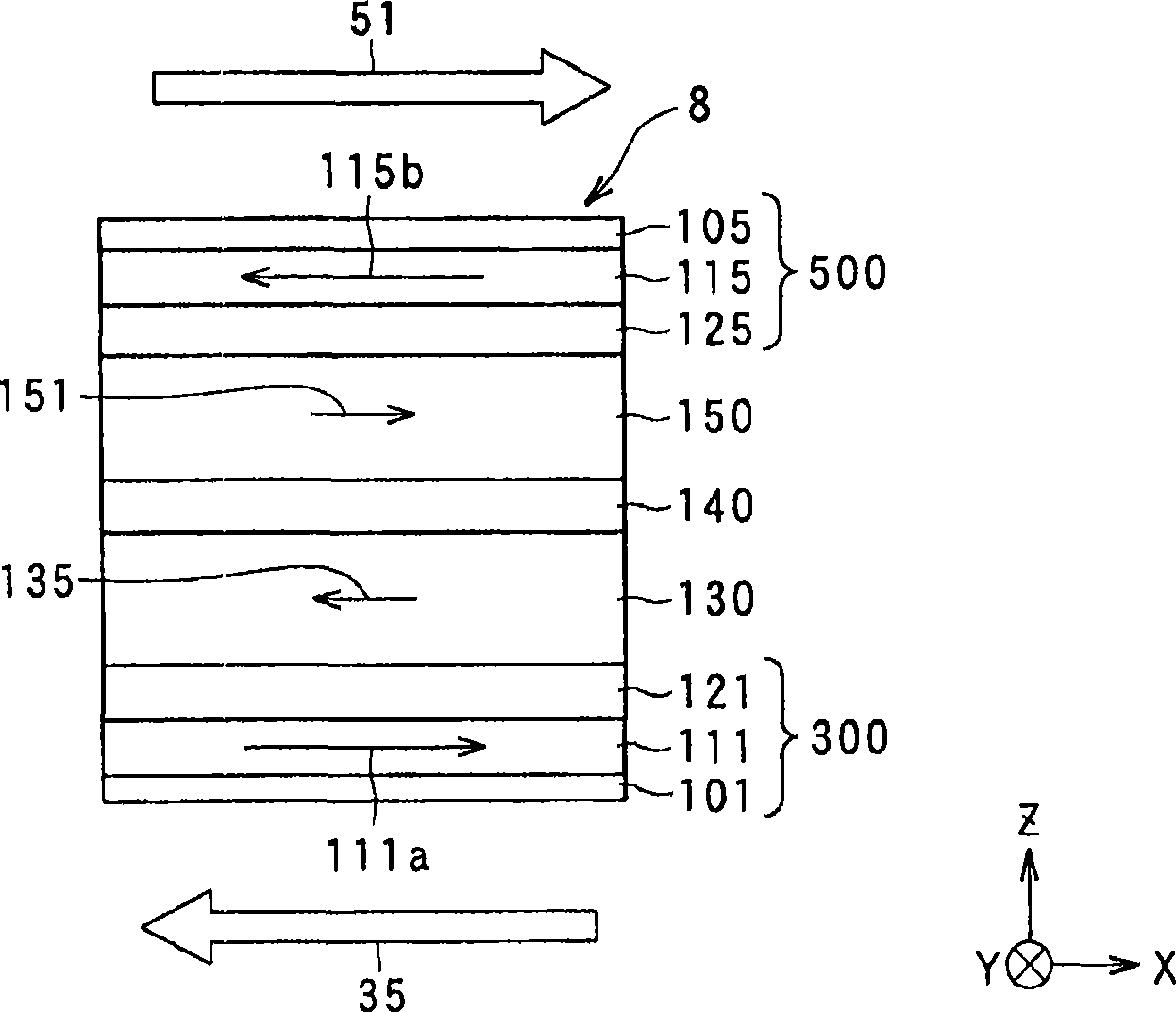

[0197] production including Figure 1 and figure 2 An experimental sample (sample of Example 1) of a magnetoresistance effect element having the structure shown.

[0198] That is, as shown in Table 1 below, on the first shield layer 3 made of NiFe with a width of 30 μm (dimensions in the X-axis direction), a length of 3 μm (dimensions in the Y-axis direction), and a thickness of 100 nm (dimensions in the Z-axis direction), A magnetoresistance effect portion 8 having a stacked structure shown in Table 1 was formed, and on this magnetoresistance effect portion 8, a width of 30 μm (dimension in the X-axis direction), a length of 3 μm (dimension in the Y-axis direction), and a thickness of 100 nm (Z The second shielding layer 5 made of NiFe. Both sides of the magnetoresistance effect part 8 are insulated by alumina.

[0199] The first shielding layer 3 and the second shielding layer 5 respectively utilize the shape anisotropy caused by the above-mentioned dimensions to form a si...

experiment example 2

[0205] In the experimental example 1 sample of the above-mentioned experimental example 1, the material of the nonmagnetic intermediate layer 140 constituting the sensor region was changed from a three-layer laminated body of Cu (thickness 0.5 nm) / ZnO (thickness 1.8 nm) / Cu (thickness 0.5 nm) Change to MgO (thickness 0.8nm).

[0206] Except for this, an experimental sample (sample of Example 2) of a magnetoresistance effect element was produced in the same manner as in Example 1 above.

[0207] Using the magnetoresistance effect of the sample of Example 2 formed in this way, a signal magnetic field from a medium corresponding to -400Oe to 400Oe was detected, and it was confirmed that a practical magnetoresistance change was obtained.

experiment example 3

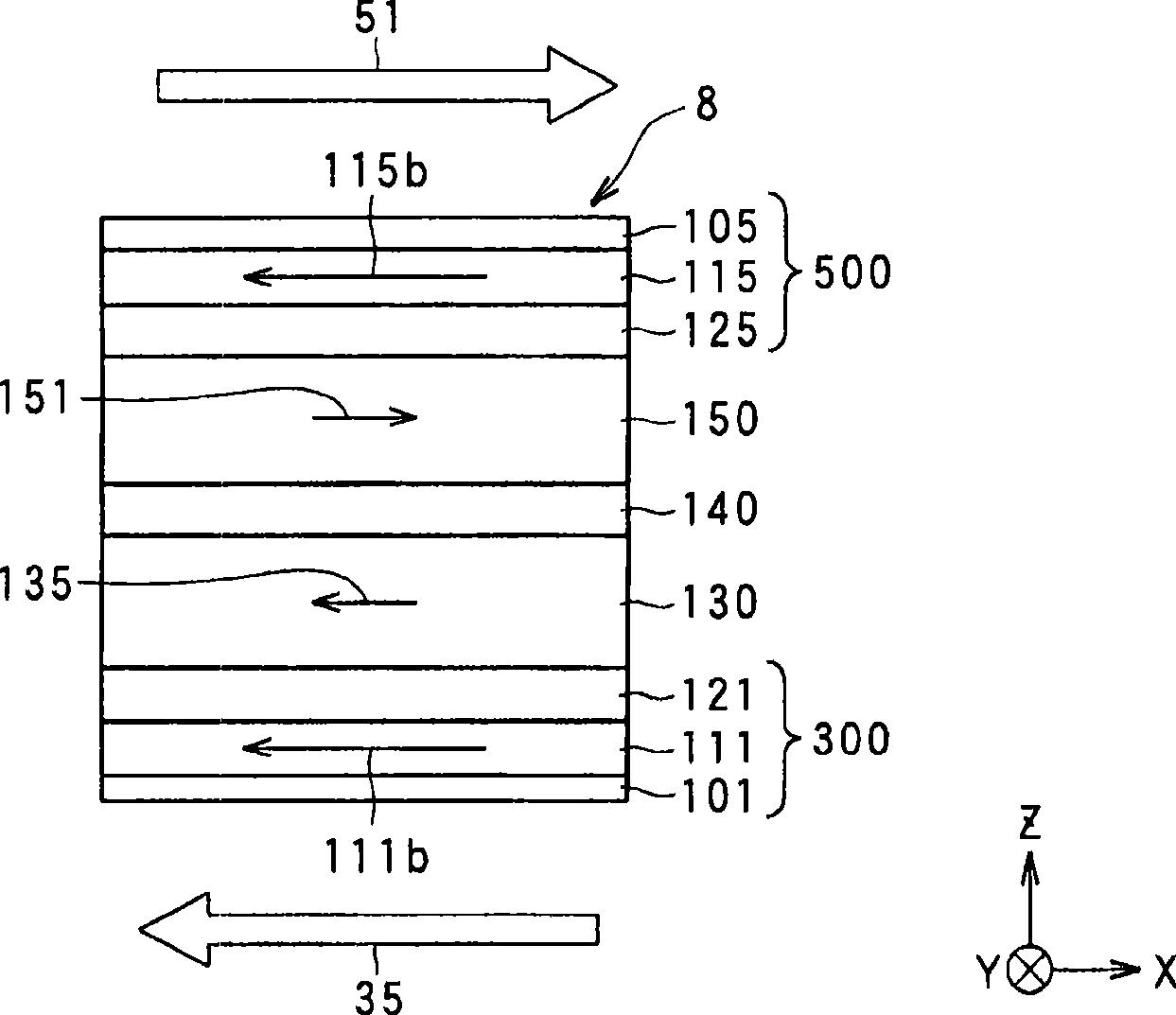

[0209] In the example 1 sample of the above-mentioned experimental example 1, the lamination structure of the first exchange coupling gap layer 300 and the second exchange coupling gap layer 500 was changed to the mode shown in the following Table 2 to produce Figure 10 Experimental sample (sample of Example 3) of the magnetoresistance effect element of the embodiment shown.

[0210] In the structure shown in Table 2, like Figure 10 As shown, the magnetization 35 of the first shielding layer 3 is antiferromagnetically coupled to the magnetization 111a of the gap adjustment layer 111, the magnetization 111a of the gap adjustment layer 111 is antiferromagnetically coupled to the magnetization 112b of the gap adjustment layer 112, and the magnetization 112b of the gap adjustment layer 112 is antiferromagnetically coupled. The magnetization 112b is antiferromagnetically coupled to the magnetization 135 of the first ferromagnetic layer 130 . Similarly, the magnetization 51 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com