Manufacture method of natto food without strange taste

A manufacturing method and technology for flavoring natto, which are applied in food preparation, food science, application and other directions, can solve the problems of not completely strange taste, affecting the widespread application of natto food, etc., and achieve adjustment and recovery of the gastrointestinal tract. Function, the effect of overcoming unpleasant smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

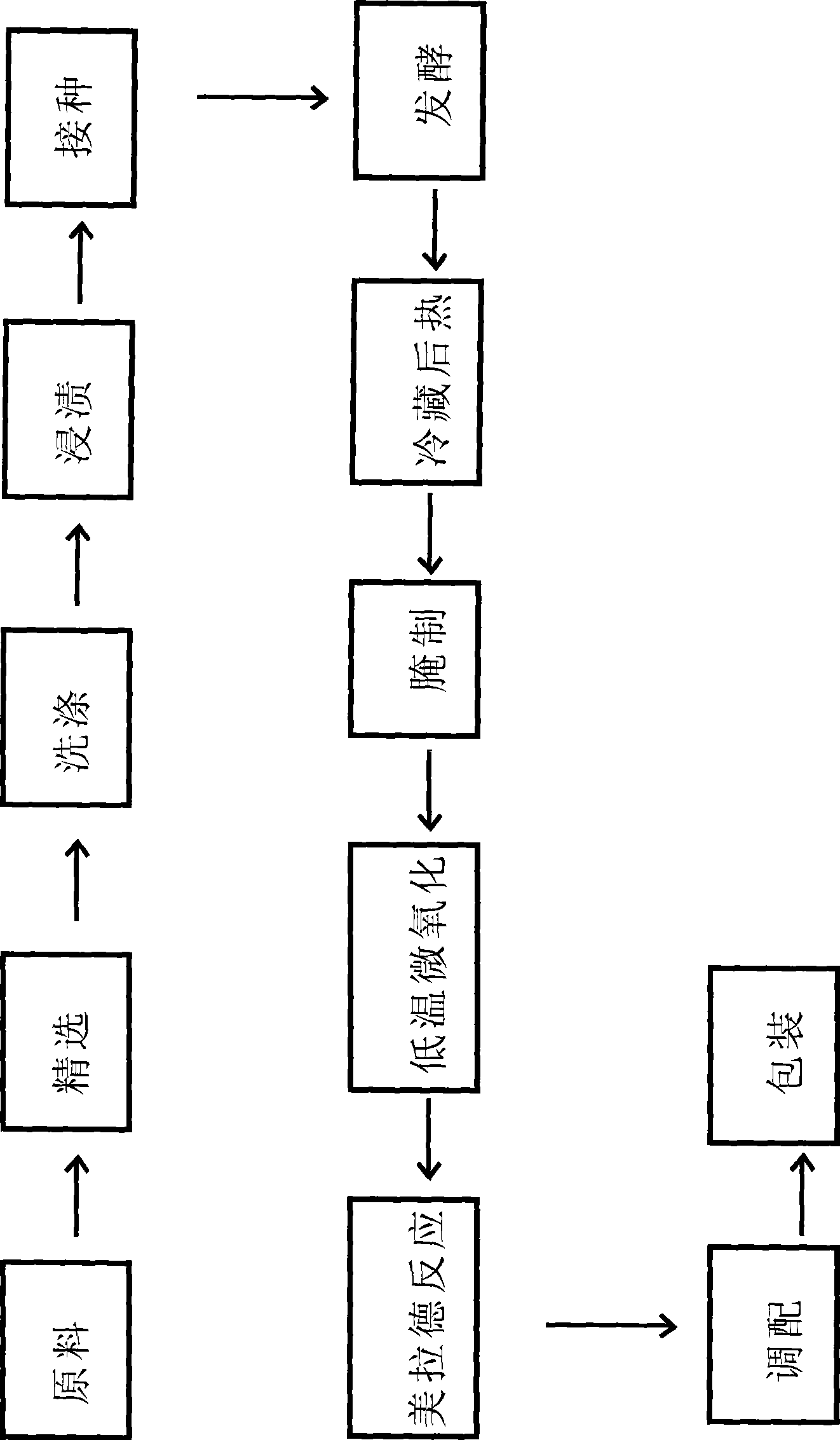

Image

Examples

Embodiment Construction

[0014] In the present invention, natto is prepared by inoculating natto bacillus with soybean and water.

[0015] The technical scheme of the invention is further described below by specific examples:

[0016] a. Using Northeast high-quality small-grain soybeans as raw materials, according to conventional techniques, after selection and washing, soak in water for 8-16 hours, remove and cook for 0.5-1.0 hours;

[0017] b. Use high-efficiency active natto strains for inoculation and fermentation, and control the fermentation time within 10-18 hours to avoid excessive fermentation and reduce the formation of odorous substances from the source;

[0018] c. After 10-20 hours, the fermented natto is cooked at a low temperature of 0-4°C to facilitate the release of odorous substances;

[0019] d, the released natto is soaked for 10-15 hours in the seasoning formula of 8-10% soy sauce, 1-3% sugar and 1-3% salt (calculated as fresh natto), and further marinated to achieve the flavor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com