Sintering composite alkaline brick for dry lime rotary kiln and method for producing the same

A rotary kiln and dry lime technology, applied in the field of dry lime rotary kiln, can solve problems such as unsuitability of composite bricks, and achieve the effects of high strength, excellent high temperature resistance and long service life

Inactive Publication Date: 2009-06-10

SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this composite brick is not suitable for use in the firing zone and transition zone of the lime rotary kiln

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0040] The preparation method of the dry lime rotary kiln for firing composite alkaline bricks comprises the following steps:

[0041] Steps of batching and mixing the working layer according to the ratio;

[0042] Steps of batching and mixing the heat insulation layer according to the proportioning ratio;

[0043] the step of co-molding the working layer and the insulating layer; and

[0044] The step of sintering the integrally molded working layer and heat insulating layer at 1550-1650°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

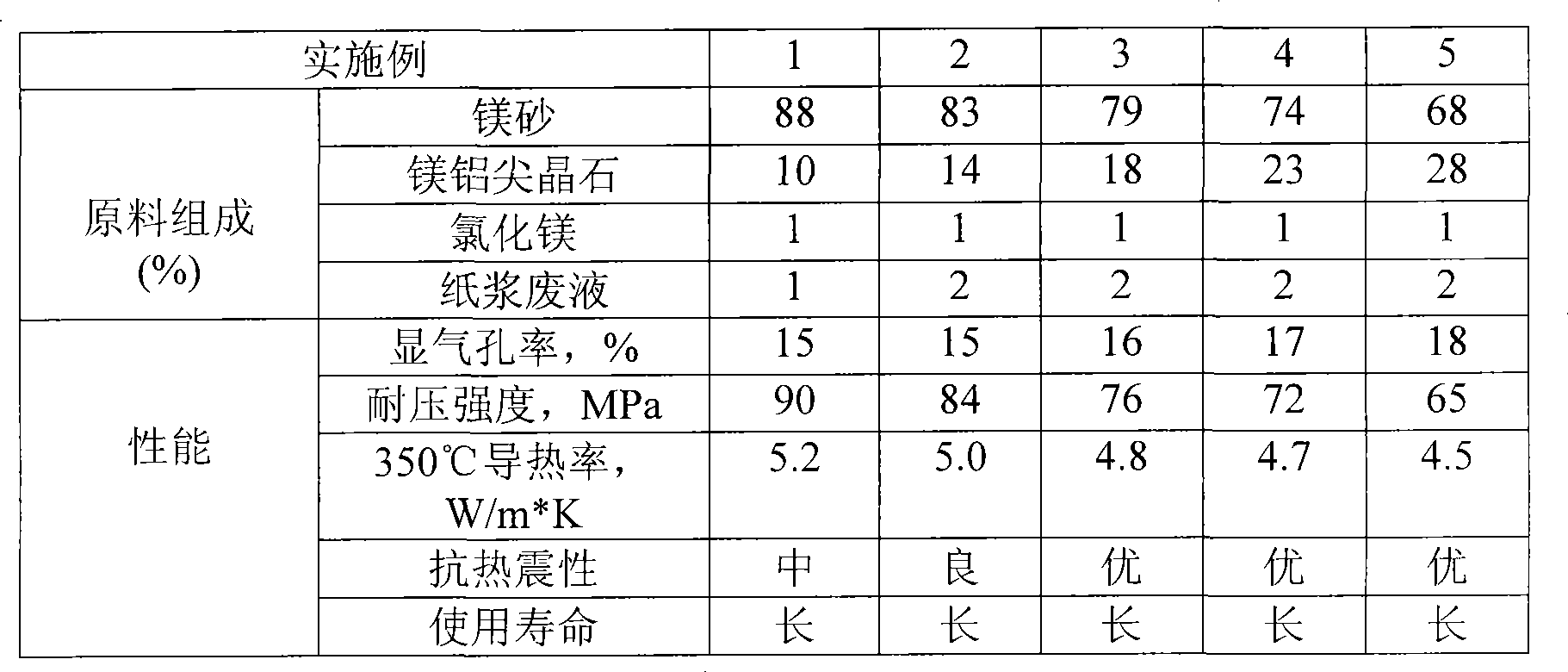

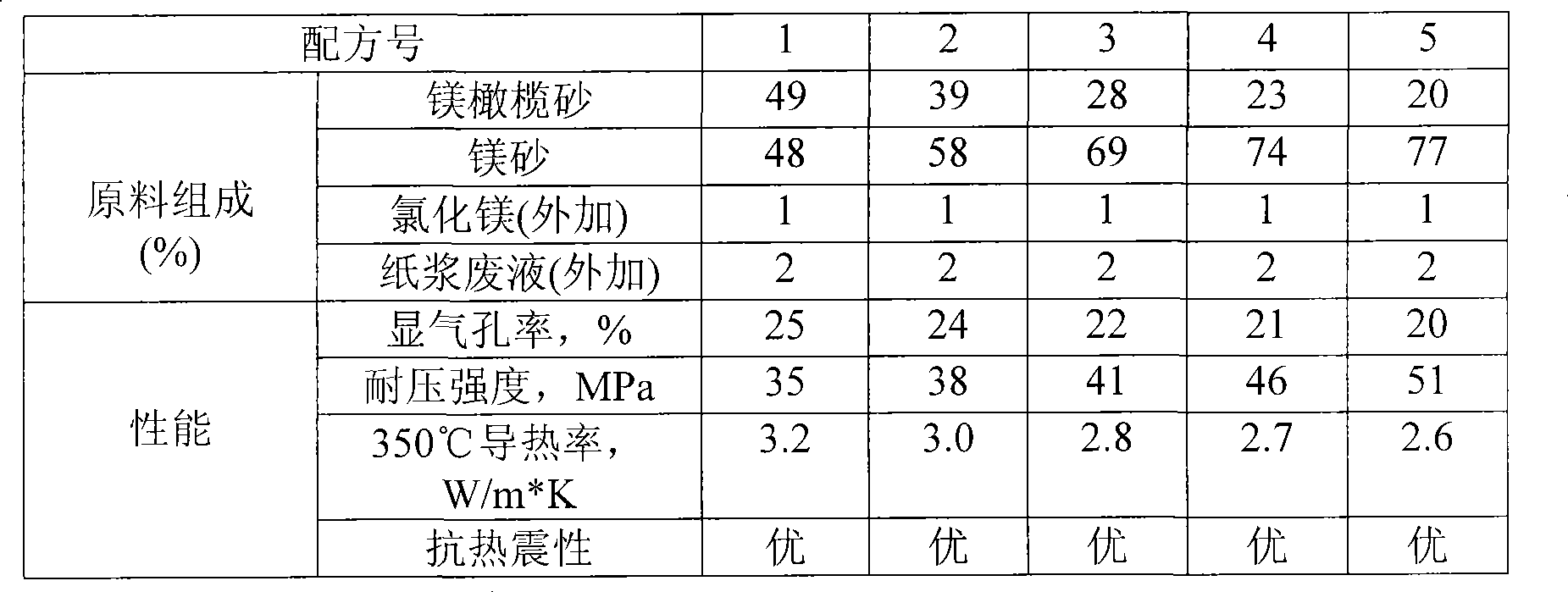

The invention relates to a dry lime rotary kiln, in particular to a composite brick for the dry lime rotary kiln. The sintered composite basic brick for the dry lime rotary kiln comprises a working layer and a heat-insulating layer, wherein the working layer mainly comprises the following compositions by weight percentage: 69 to 88 percent of magnesite with a magnesia content of more than 96 percent, and 10 to 28 percent of magnalium spinel with a magnesia content of more than 20 percent; and the heat-insulating layer mainly comprises the following compositions by weight percentage: 48 to 77 percent of magnesite with a magnesia content of more than 96 percent, and 20 to 49 percent of forsterite with a magnesia content of more than 20 percent. The sintered composite basic brick for the dry lime rotary kiln has the properties of high temperature resistance, alkali resistance, abrasion resistance and so on, can be used for calcining zones and transition zones of the lime kiln and a cement kiln, can realize the aims of energy conservation and consumption reduction, and has long service life.

Description

technical field [0001] The invention relates to a dry lime rotary kiln, in particular to a composite brick for a dry lime rotary kiln. Background technique [0002] Magnesia-spinel bricks and magnesia-chrome bricks are usually used in the firing zone of large lime kilns and cement kilns. Because of their high thermal conductivity, they often lead to overheating of the cylinder in this part. Overheating of the cylinder increases the probability of damage to mechanical equipment and accelerates the body deformation, and the deformation of the cylinder accelerates the mechanical damage of the inner lining, resulting in brick falling, kiln shutdown, and affecting the operating rate of the rotary kiln. [0003] Chinese patent CN96226710.4 proposes a low-carbon high-magnesium spinel composite brick. This utility model relates to a low-carbon high-magnesium spinel composite brick suitable for the firing zone of a cement rotary kiln. It consists of refractory materials. The main bo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66C04B35/04

Inventor 宋飞金从进陈金荣张斌李泽亚励军

Owner SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap