Floating wave power machine

A wave power machine and floating technology, applied in the field of floating wave power machine, can solve the problems of easy damage, difficulty in mooring, undeveloped wave power generation, etc., and achieve the effect of high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

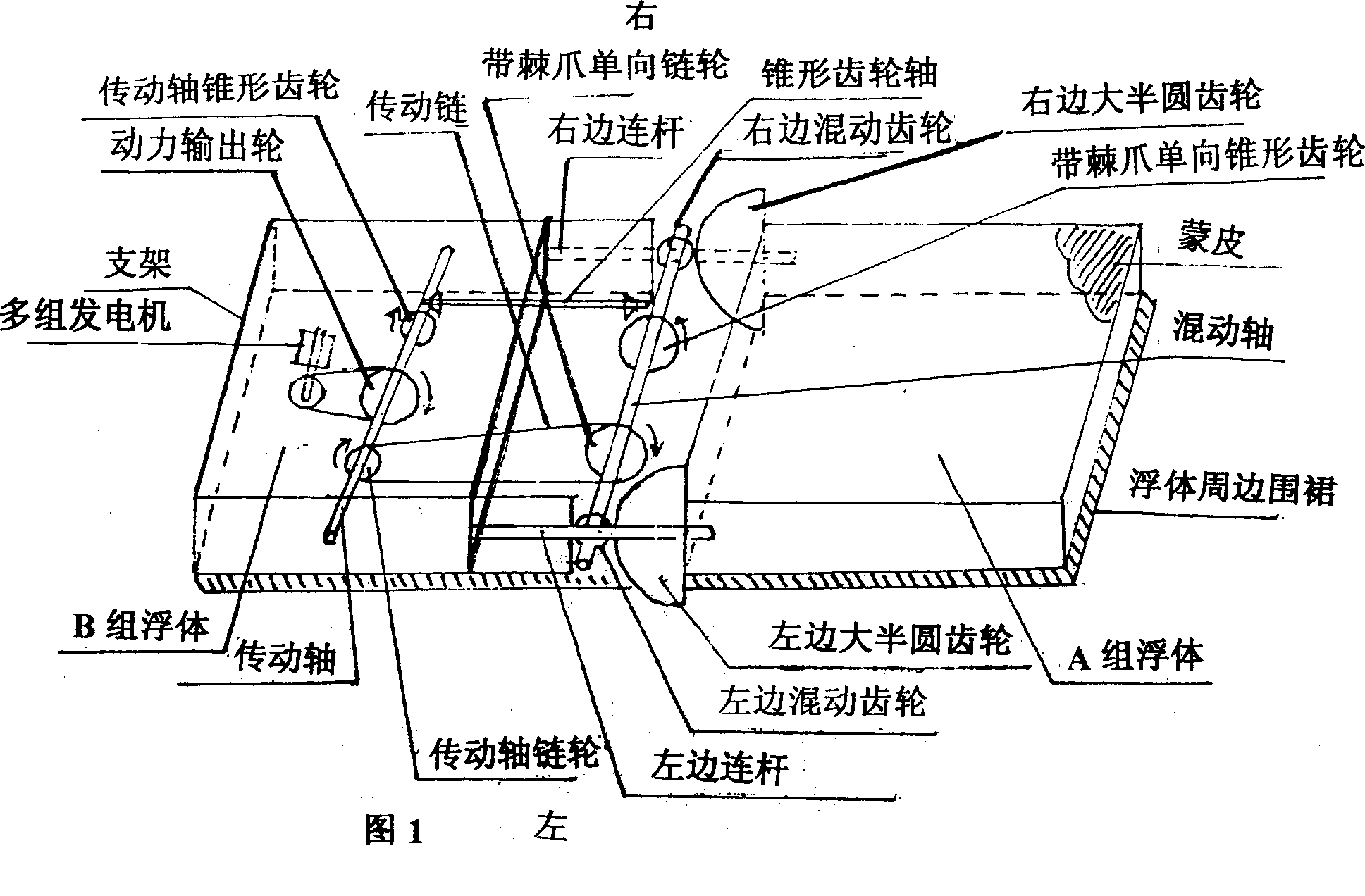

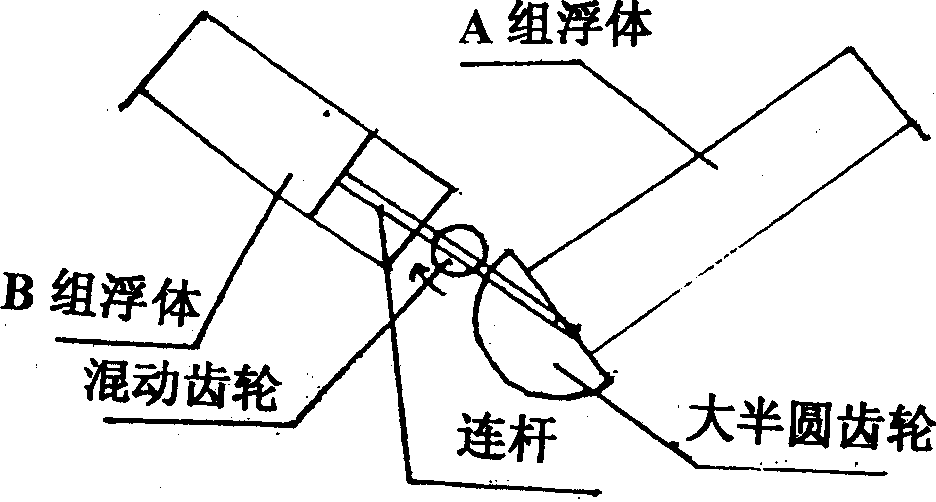

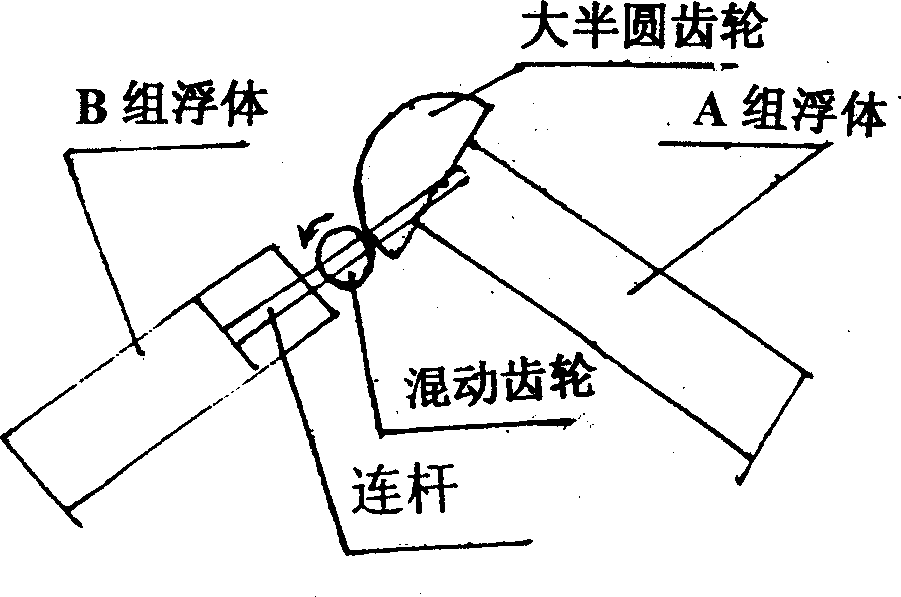

[0012] See Figure 1- figure 2 one image 3 , the floating wave force machine has a flat square structure, large semicircular gears, hybrid gears, connecting rods are installed on both sides of the two sets of floating bodies, hybrid shafts, one-way gears, transmission shafts, transmission couplings, and bevel gear shafts , power output wheel, and multiple sets of generators are installed in the buoyant support of group B, and the apron is installed under the periphery of the floating body. The two groups of floating bodies are uplifted or collapsed by waves to form a ∧ or ∨ shape, so that the hybrid gear moves back and forth along the large semicircular gear To obtain positive and negative rotation, drive two sets of one-way gears and a transmission chain, and the bevel gear shaft through the hybrid shaft to obtain one-way rotation of the transmission shaft to output power for power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com