Engine with high-efficient output

An engine and high-efficiency technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as the inability to efficiently use high-pressure gas kinetic energy, and achieve the effects of simple and practical structure, improved efficiency, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

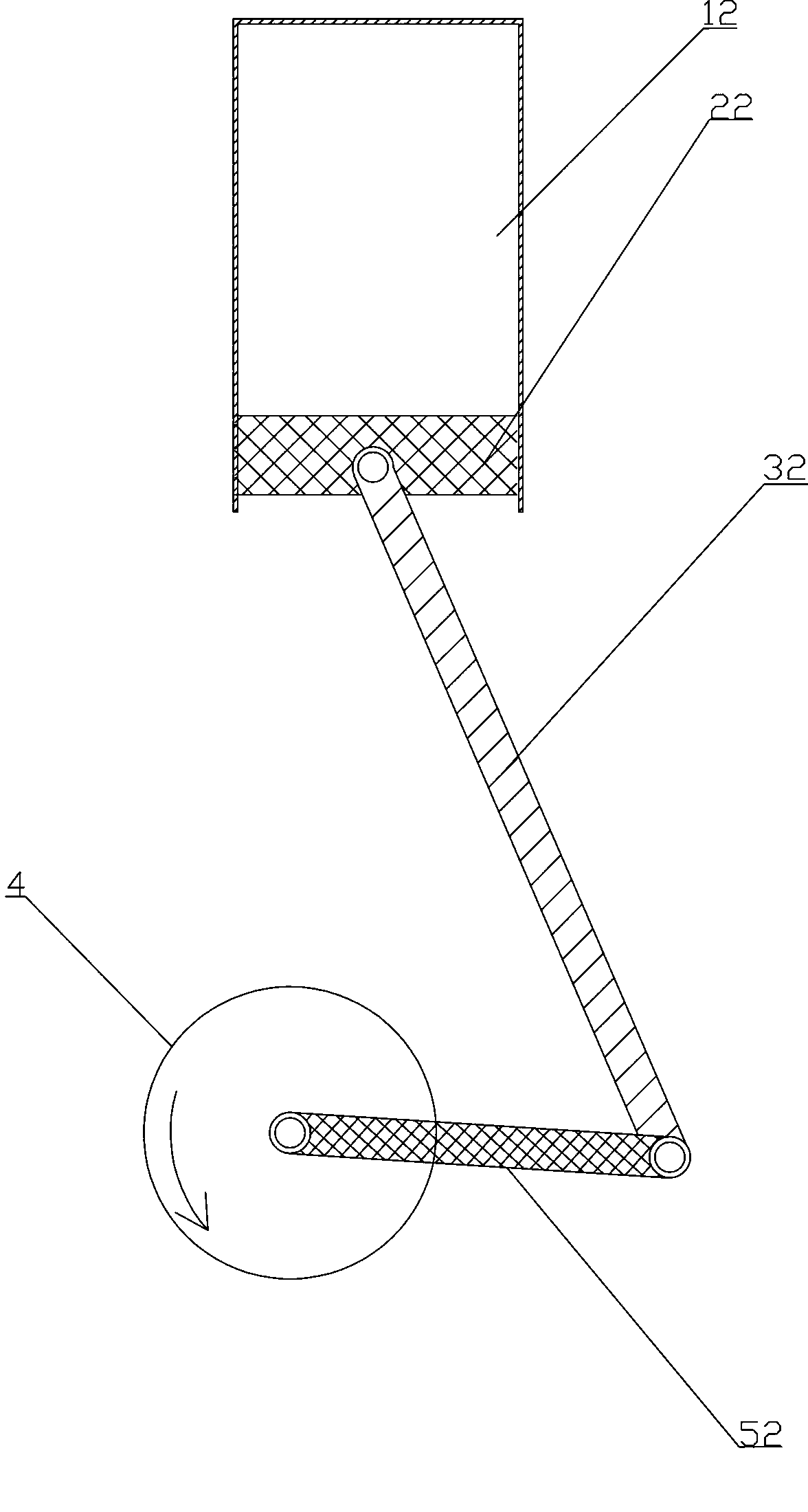

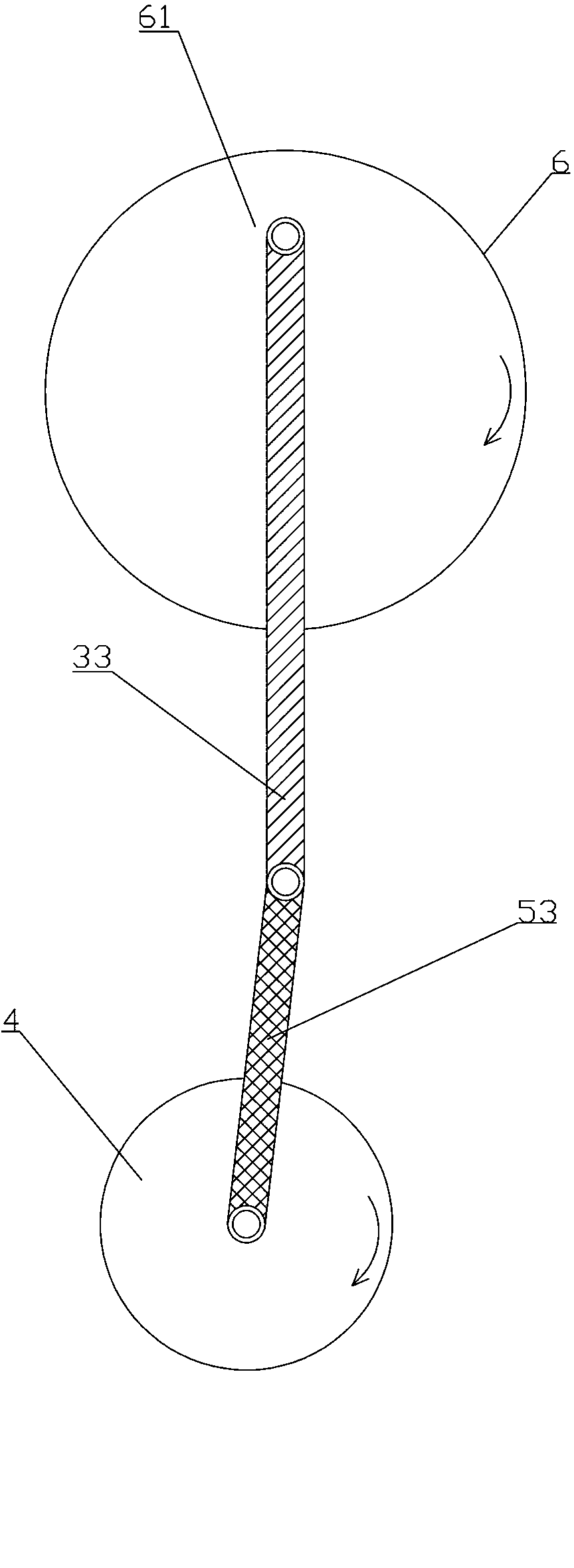

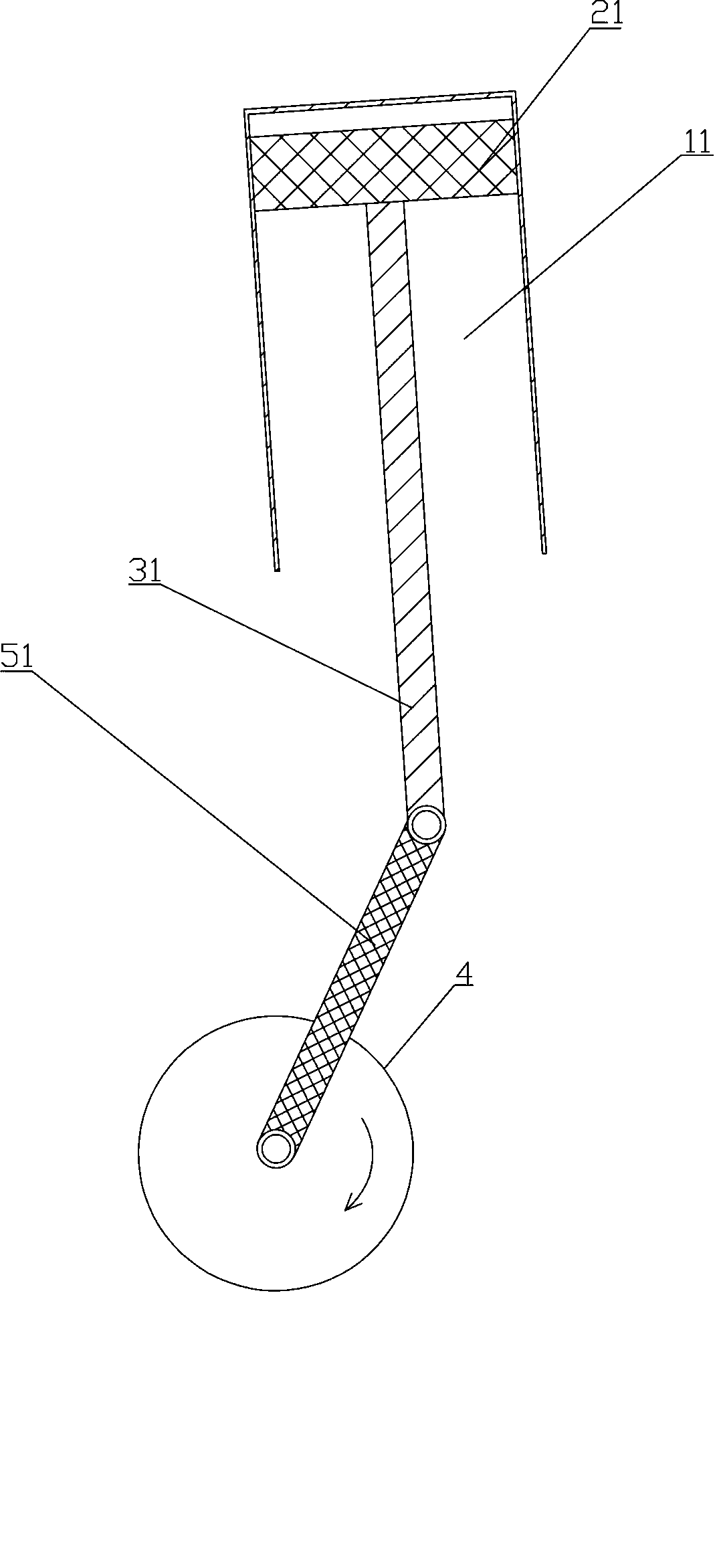

[0023] Such as figure 1 , figure 2 , Figure 5 As shown, a high-efficiency output engine includes two groups of cylinders, two groups of pistons, two groups of connecting rods and crankshaft 4, wherein the cylinders, pistons and connecting rods are respectively the first cylinder 11 and the second cylinder 12, the first piston 21 and the second piston 22, the first connecting rod 31 and the second connecting rod 32, the crankshaft 4 is provided with three interlocking first crank 51, second crank 52 and third crank 53, the first connecting rod 31 and one end of the second connecting rod 32 are respectively rotatably connected to the above-mentioned first piston 21 and the second piston 22, and the other ends are respectively rotatably connected to the above-mentioned first crank 51 and the second crank 52, the first piston 21 and the second piston 22 are respectively arranged in the above-mentioned first cylinder 11 and the second cylinder 12; the crankshaft 4 is provided w...

Embodiment 2

[0026] Such as Figure 6 , Figure 7 As shown, the difference between this embodiment and the first embodiment is that in the second embodiment, the movement direction of all the pistons is the same as the movement direction of the connecting rods connected thereto, and all the cylinders can be biased to swing with the movement of the connecting rods The other structures and principles are exactly the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com